74

Regulation of the external sensor (fig.

26/a)

If an external sensor is installed, the value

of the output temperature is automatically

chosen by the system, which quickly adjusts

the environmental temperature on the ba-

sis of the external temperature. If you wish

to change the value of the temperature, in-

creasing or decreasing that calculated au-

tomatically by the electronic card, proceed

as indicated in the preceding paragraph.

The level of various correction of a value of

temperature proportional calculated. The di-

splay will be as shown in fig. 26/a.

REGULATION OF THE D.H.W.

TEMPERATURE (fig. 27)

To set the desired temperature D.H.W.,

press the key of the controls (pos. 2).

The display will be as shown in the figure.

Change the values with the key

and

.

The display will return to the standard

visualisation by pressing the key again,

or after 10 seconds if no key is pressed.

TO SWITCH OFF THE BOILER

(fig. 25)

In the case of a short absence, press the

key of the controls (pos. 2). The display

will be as shown in the figure 25. In this way,

leaving the electricity and the fuel supply

connected, the boiler is protected from frost

and from the pump becoming blocked. If the

boiler is not used for a prolonged period, it

is advisable to disconnect the electricity sup-

ply, by switching off the main switch of the

system, and to close the gas tap and, if low

temperatures are expected, to completely

empty the hydraulic circuits to avoid pipes

being broken by the formation of ice in the

pipes.

ANOMALIES AND SOLUTIONS

When there is a functioning anomaly, the di-

splay shows an alarm and the blue luminous

bar becomes red. Descriptions of the ano-

malies with the relative alarms and solutions

are given below:

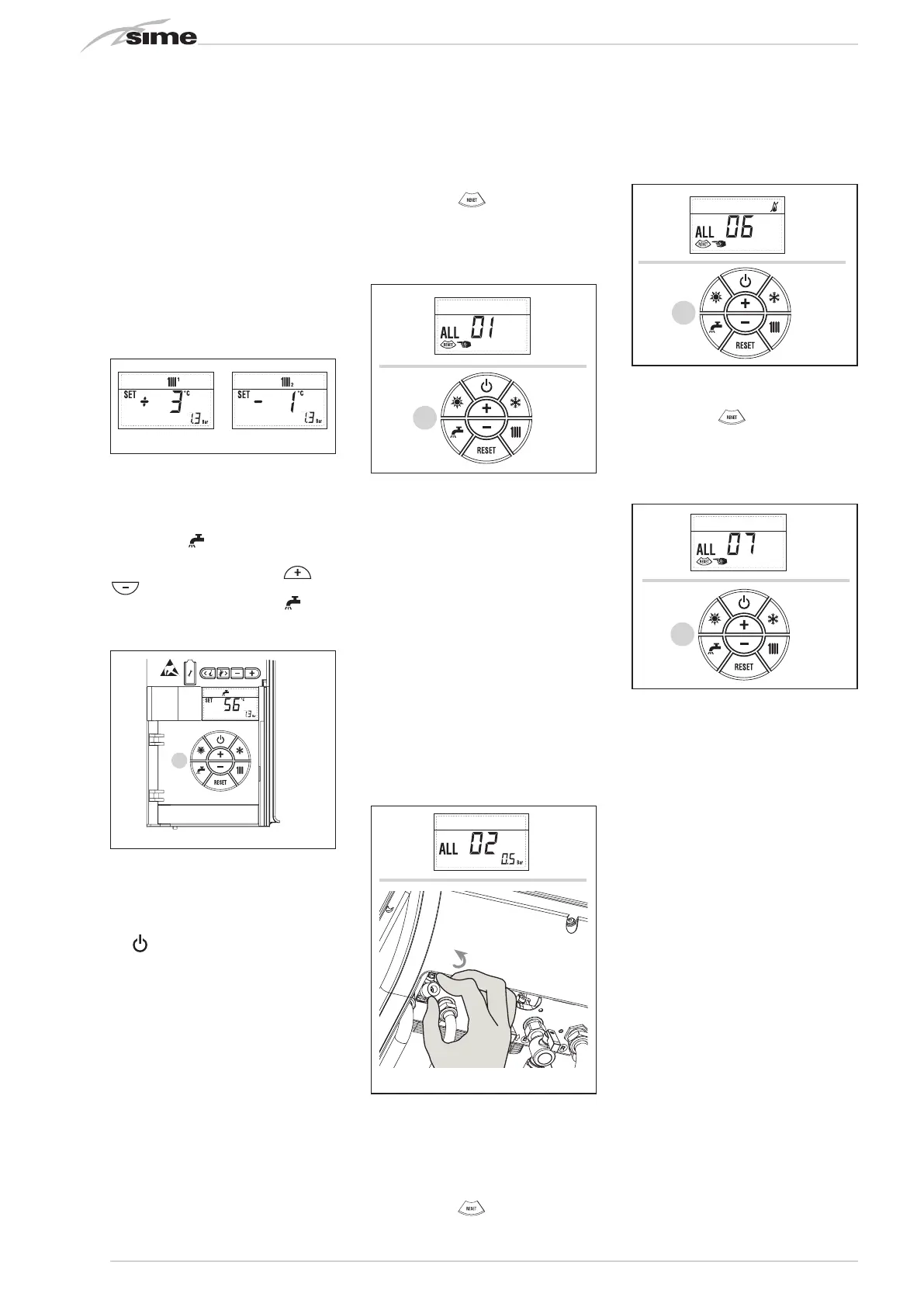

– ALL 01 (fig. 28)

Press the key

of the controls (2) to

re-start the boiler.

If the anomaly persists, request the in-

tervention of qualified technical person-

nel.

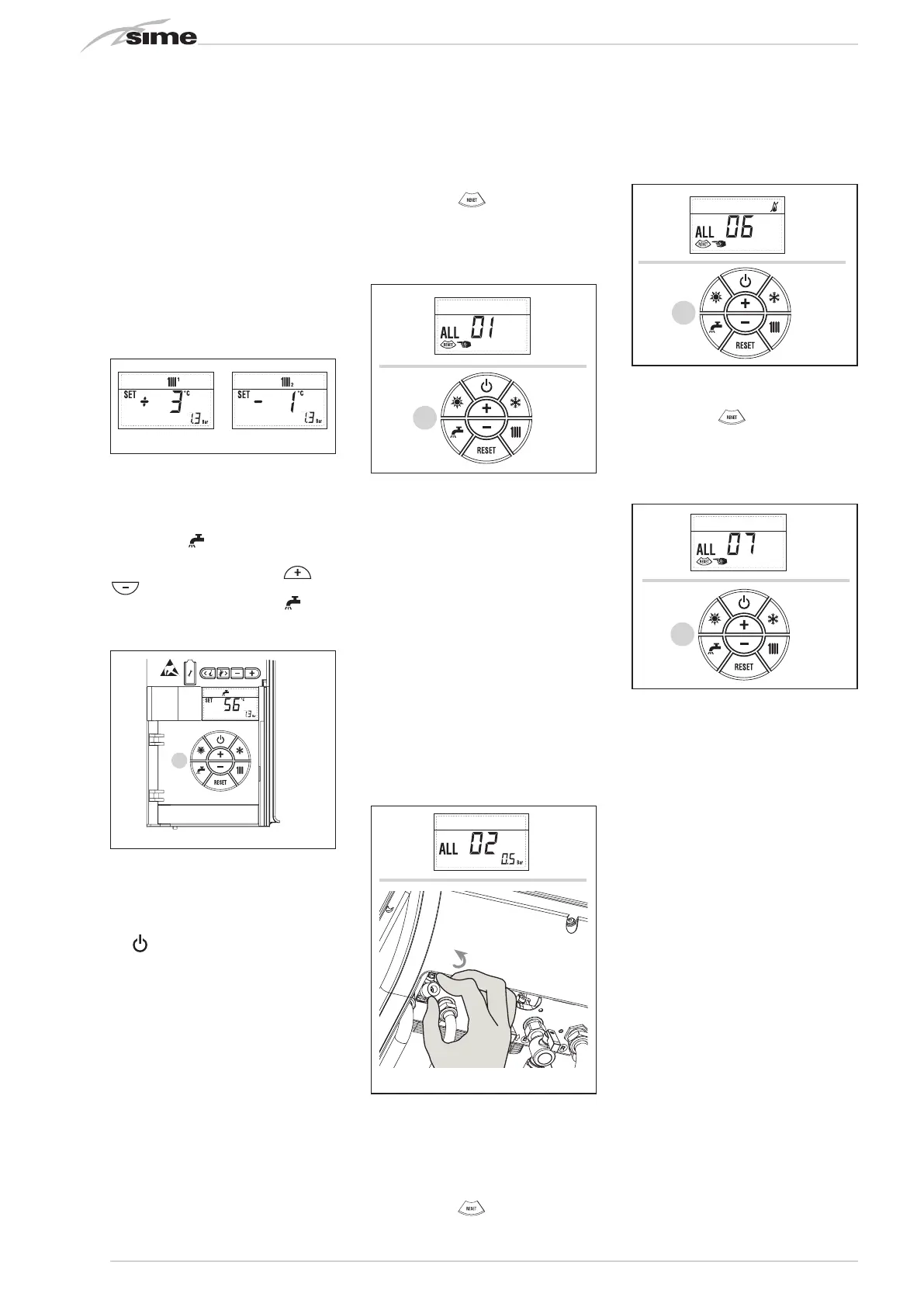

– ALL 02 (fig. 28/a)

If the water pressure detected is lower

than 0.5 bar, the boiler will stop and the

display will show “ALL 02”.

Bring the pressure back to normal by ac-

ting on the loading knob. Lower the knob

and turn it anti-clockwise to open until

the pressure indicated by the display is

between 1 and 1.5 bars.

WHEN FILLING HAS BEEN COMPLE-

TED, CLOSE THE KNOB BY TURNING IT

CLOCKWISE.

If it is necessary to repeat the system

loading procedure, it is advisable to

contact qualified technical personnel to

check the seal of the heating system (to

check whether there are any leaks).

– ALL 03/ALL 04/ALL 05

Request assistance from qualified tech-

nical personnel.

– ALL 06 (fig. 28/c)

Press the key

of the controls (2) to

re-start the boiler.

If the anomaly persists, request assistan-

ce from qualified technical personnel.

– ALL 07 (fig. 28/d)

Press the key

of the controls (2) to

re-start the boiler.

If the anomaly persists, request assi-

stance from qualified technical person-

nel.

– From “ALL 08” to “ALL 29”

Request assistance from qualified tech-

nical personnel.

GAS CONVERSION

If it is necessary to change to a different

type of gas, request assistance only from

authorised technical personnel.

MAINTENANCE

Annual maintenance of the appliance

should be planned sufficiently in advance,

requesting the assistance of authorised

technical personnel.

DISPOSAL OF THE EQUIPMENT

(EUROPEAN DIRECTIVE 2002/96/CE)

Once it reaches the end of its operating life,

the equipment MUST BE RECYCLED in line

with current legislation.

IT MUST NOT be disposed of together with

urban waste.

It can be handed over to recycling centres, if

there are any, or to retailers that offer this

service.

Recycling prevents potential damage to the

environment and health. It allows to reco-

ver a number of recyclable materials, with

considerable savings in terms of money and

energy.

Apre

2

2

2

Circuito

riscaldamento 2

Circuito

riscaldamento 3

(impianto tre

zone)

Fig. 26/a

2

Circuito

riscaldamento 2

Circuito

riscaldamento 3

(impianto tre

zone)

Fig. 27

Apre

2

2

2

Circuito

riscaldamento 2

Circuito

riscaldamento 3

(impianto tre

zone)

APRE

Fig. 28/a

OPEN

Apre

2

2

2

Circuito

riscaldamento 2

Circuito

riscaldamento 3

(impianto tre

zone)

2

2

Circuito

riscaldamento 2

Circuito

riscaldamento 3

(impianto tre

zone)

Fig. 28

Apre

2

2

2

Circuito

riscaldamento 2

Circuito

riscaldamento 3

(impianto tre

zone)

2

2

Circuito

riscaldamento 2

Circuito

riscaldamento 3

(impianto tre

zone)

Fig. 28/d

Apre

2

2

2

Circuito

riscaldamento 2

Circuito

riscaldamento 3

(impianto tre

zone)

2

2

Circuito

riscaldamento 2

Circuito

riscaldamento 3

(impianto tre

zone)

Fig. 28/c

Loading...

Loading...