106

NOTE: the inside of the upper door of the

boiler panel has a label with the values

that have to be set for PAR 1 and PAR 2

(fig. 19).

3.3.2 Warning

Should the boiler operation not be optimal

but no alarm sets off, press the button

until info 70 and the warning code

associated to the ongoing event are

displayed.

Once optimal operation is restored, info 70

will display: “- -”.

Below is the table of warning codes:

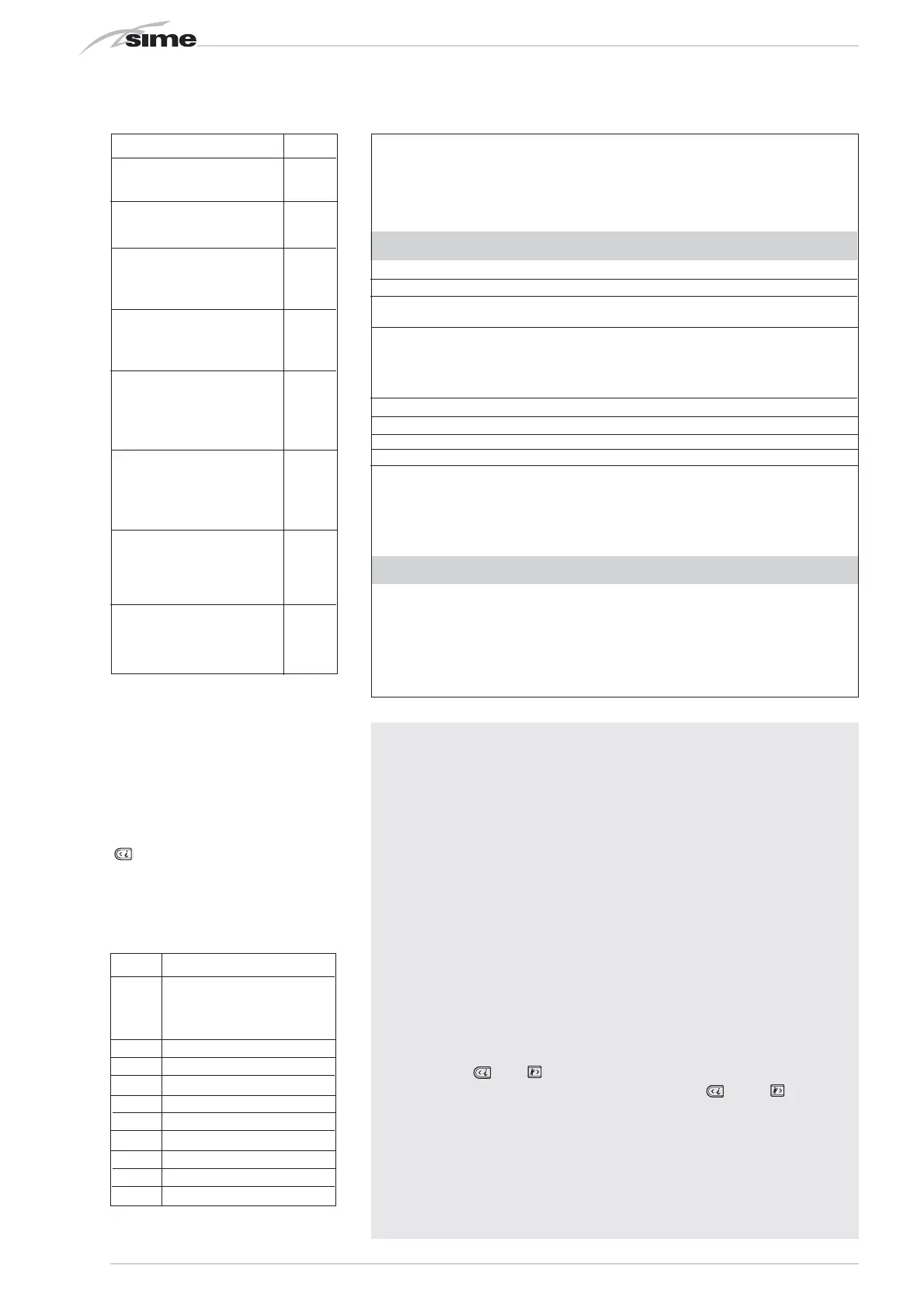

PARAMETERS INSTALLER

EXPANSION CARD

PAR DESCRIPTION RANGE UNIT OF INC/DEC DEFAULT

MEASUREMENT UNIT SETTING

40 Number of expansion boards 0 ... 3 = 1 0

41 Mix valve stroke time 0 ... 199 10 sec. 1 12

42

Priority of D.H.W. over mixed zone

0 = Paralle = = 1

1 = Absolute

43 Floor drying 0 = No activated = = 0

1 = Curve A

2 = Curve B

3 = Curve A+B

44 Type of solar system 1 ... 8 = 1 1

45

∆

t solar collector pump 1 PAR 74 OEM - 1... 50 °C 1 8

46 Solar integration delay “--”, 0 ... 199 Min. 1 0

47 Tmin solar collector “--”, -30 ... 0 °C 1 - 10

48 Tmax solar collector “--”, 80 ... 199 °C 1 120

PARAMETERS RESTORATION

PAR DESCRIPTION RANGE UNIT OF INC/DEC DEFAULT

MEASUREMENT UNIT SETTING

49 * Reset default parameters -- , 1 = = =

(par 01 - par 02 = “-“)

* In case of difficulty in understanding the current setting or in case of an anomalous or

incomprehensible conduct of the boiler, we suggest to restore the initial values of the parameters

setting PAR 49 = 1 and the PAR 1 and PAR 2 as specified at point 3.3.1.

BOILER PAR 2

Instant with deviator valve 1

and flowmeter

Instant with deviator valve, 2

flowmeter and solar combination

D.H.W. tank with

deviator valve and boiler sensor 3

vers. T (LOW INERTIA)

On board D.H.W. tank with

deviator valve and D.H.W. sensor 4

(LOW INERTIA)

Remote D.H.W. tank with deviator

valve and D.H.W. thermostat 5

or heating only vers. T/R boiler

(LOW INERTIA)

On board D.H.W. tank with

double pump and D.H.W. sensor 6

vers. T/R boiler

(LOW INERTIA)

On board D.H.W. tank with

double pump and D.H.W.

thermostat vers. T/R boiler 8

(LOW INERTIA)

Only heating with

antifreeze sensor

9

(LOW INERTIA)

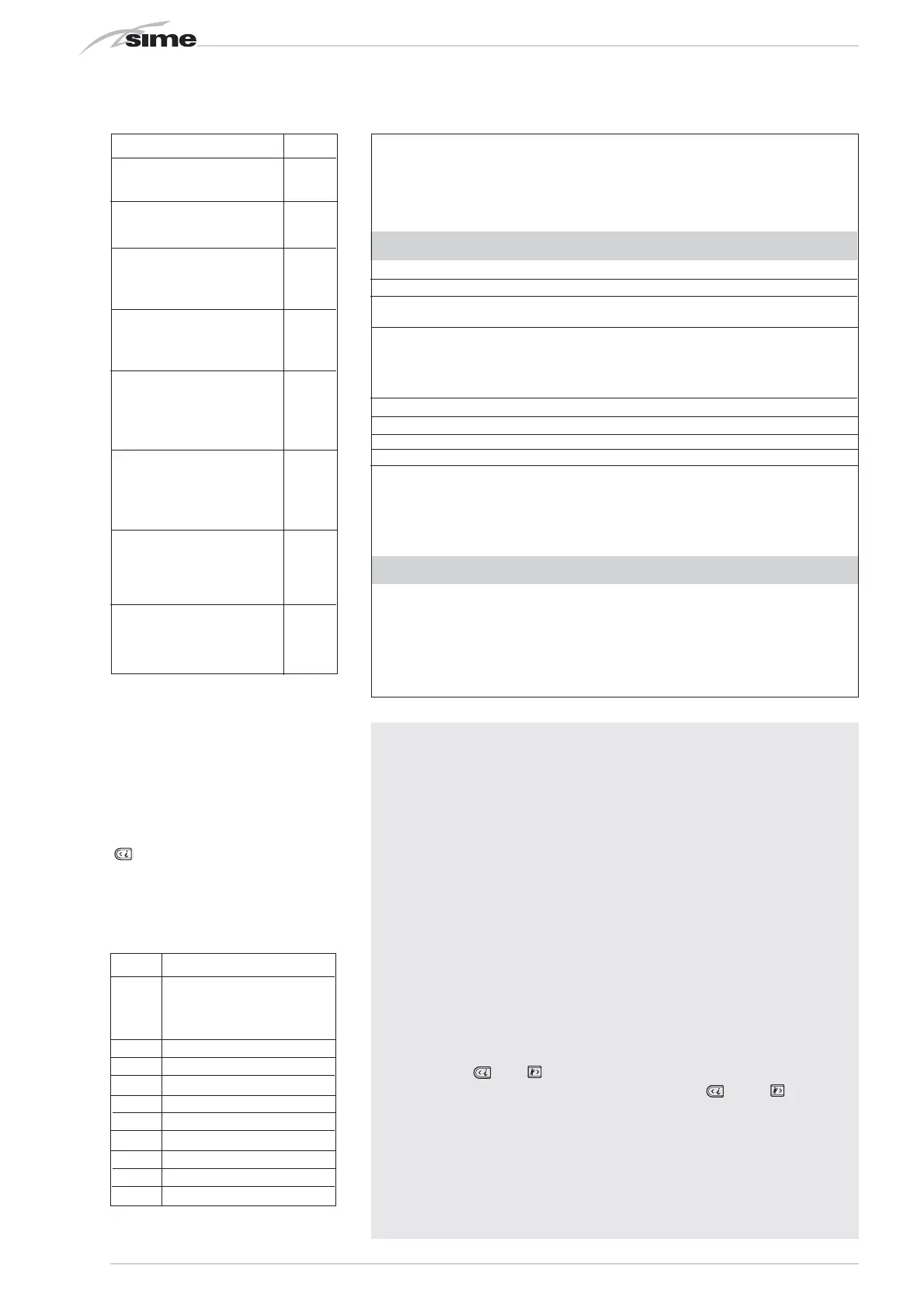

CODE DESCRIPTION

E0 Reduced capacity operation

(

∆

t between delivery and return

over 40°C)

E1 Shorted external sensor (SE)

E2 Preheating function active

E3 TBD

E4 TBD

E5 TBD

E6 TBD

E7 TBD

E8 TBD

E9 TBD

CASCADE CONNECTION PARAMETERS

When the unit is installed in sequence / cascade (modular

system with multiple generators) must be changed on the

first boiler and the other in succession of the following para-

meter INST:

PAR 15 = 0 for the first boiler (MASTER)

1 .... 7 for the other boilers (SLAVE)

(Avoid assigning the same number to SLAVE

boilers)

In addition, when the number of boilers in cascade is more

than two, configure the parameters OEM A1 of the MASTER

boiler.

To access the OEM parameters press simultaneously the

buttons ( and ) for 2 seconds. Entered in the INST level

again press simultaneously he buttons ( and ) for

another 2 seconds. At this point insert the access code for-

med by this sequence of INSTALLATOR BUTTONS:

“ + / - / < / > / < “.

Set the parameter:

PAR A1 = Number of cascade generators (3 ... 8)

Loading...

Loading...