••• 4 •••

A

C

B

VENT PLUG OIL FILL LOCATION IS APPLICABLE

TO THE 1.5, 2.5, GALLON RESERVOIRS

3.0 TECHNICAL SPECIFICATIONS

G5 Air Torque Series

Operating Pressure 10,000 PSI (700kg/cm

2

)

Motor Rating Rotary Air Valve, 3 hp Motor (3,000 rpm)

90 psi / 50 cfm

Flow Rate 700 cu. in./ min. @ 1,100 psi, 55 cu. in / min. @ 10,000 psi

Maximum Operating Temperature 170F - (65C)

4.0 WORKING PRESSURE

The pump’s maximum working pressure is 10,000 PSI (700kg/cm

2

). Make sure that all hydraulic equipment such as

rams, hoses, etc. used with this pump are rated at 10,000 PSI (700kg/cm

2

) operating pressure.

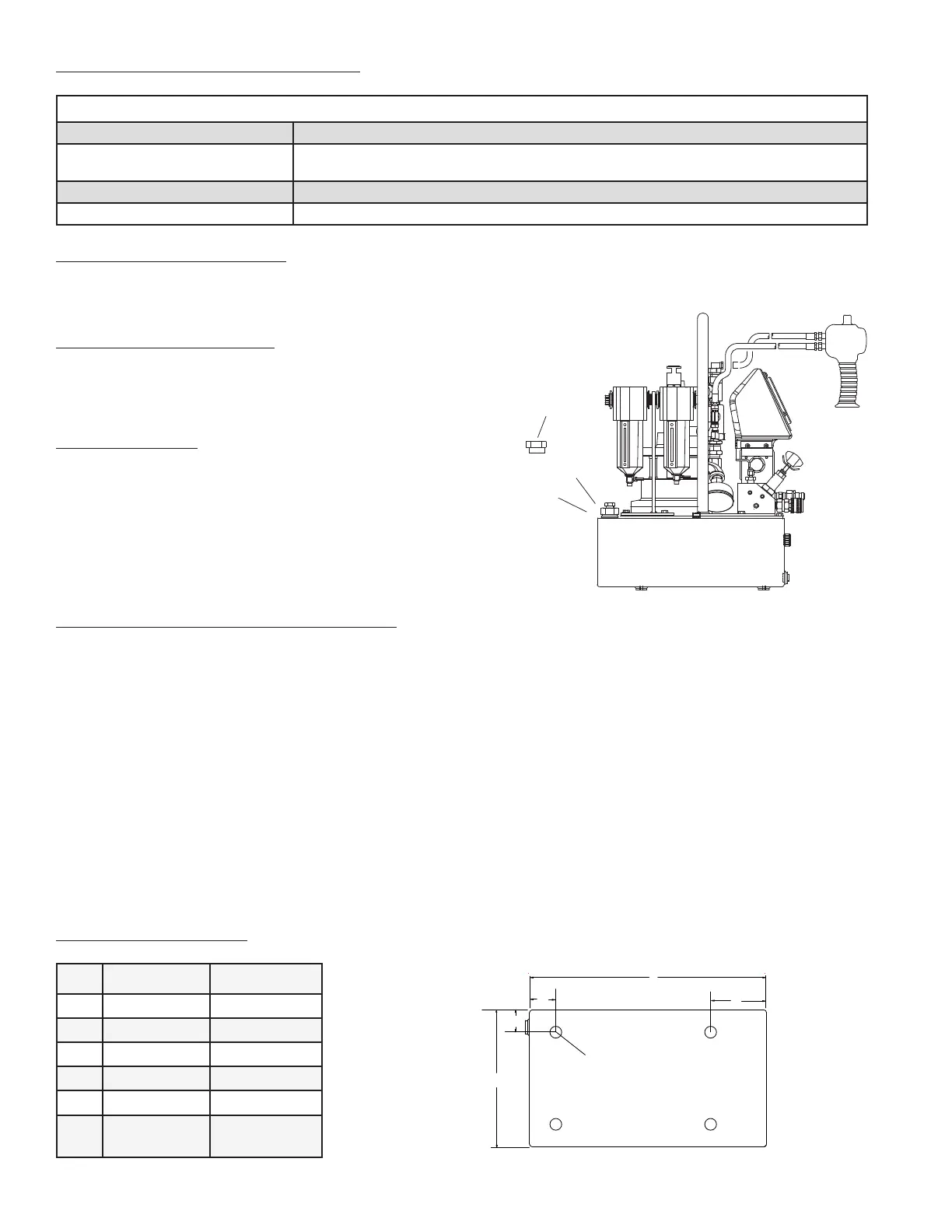

4.1 INSTALL VENT PLUG

Remove SHIPPING PLUG (A) and install VENT PLUG (B) into cover

plate.

4.2 ADDING OIL

Remove OIL FILLER CAP (C) and add SIMPLEX Hydraulic Oil into

reservoir. Oil level should not exceed 1” from the reservoir cover.

As a “rule of thumb” oil should be visual in site window when the

unit is powered down and all connected tools or cylinders are

retracted.

4.3 CONNECTING HYDRAULIC TOOLS

Use only tools, hoses and accessories rated at 10,000 PSI (700kg/cm

2

). When making connections with quick dis-

connect couplings, make sure the couplings are fully engaged. Threaded connections such as ttings, gauges, etc.

must be securely tightened and leak free. Use 1.5 wraps of Teon tape (or suitable thread sealant) on all threads,

leaving the rst complete thread free of tape to ensure no foreign matter enters the hydraulic circuit.

WARNING: Loose or improperly threaded ttings can be potentially

dangerous if pressurized; however, severe over tightening can cause premature thread failure. Fittings need to be

tightened secure & leak free. Never hold or stand directly in line with any hydraulic connections while pressurizing.

Never grab, touch or in any way come in contact with a hydraulic pressure leak.

Escaping oil can penetrate the skin and a serious injury can result.

CAUTION: Do not subject the hose to potential hazards such as sharp surfaces, extreme heat or heavy impact.

Do not allow the hose to kink or twist. Inspect each hose for wear before it is used.

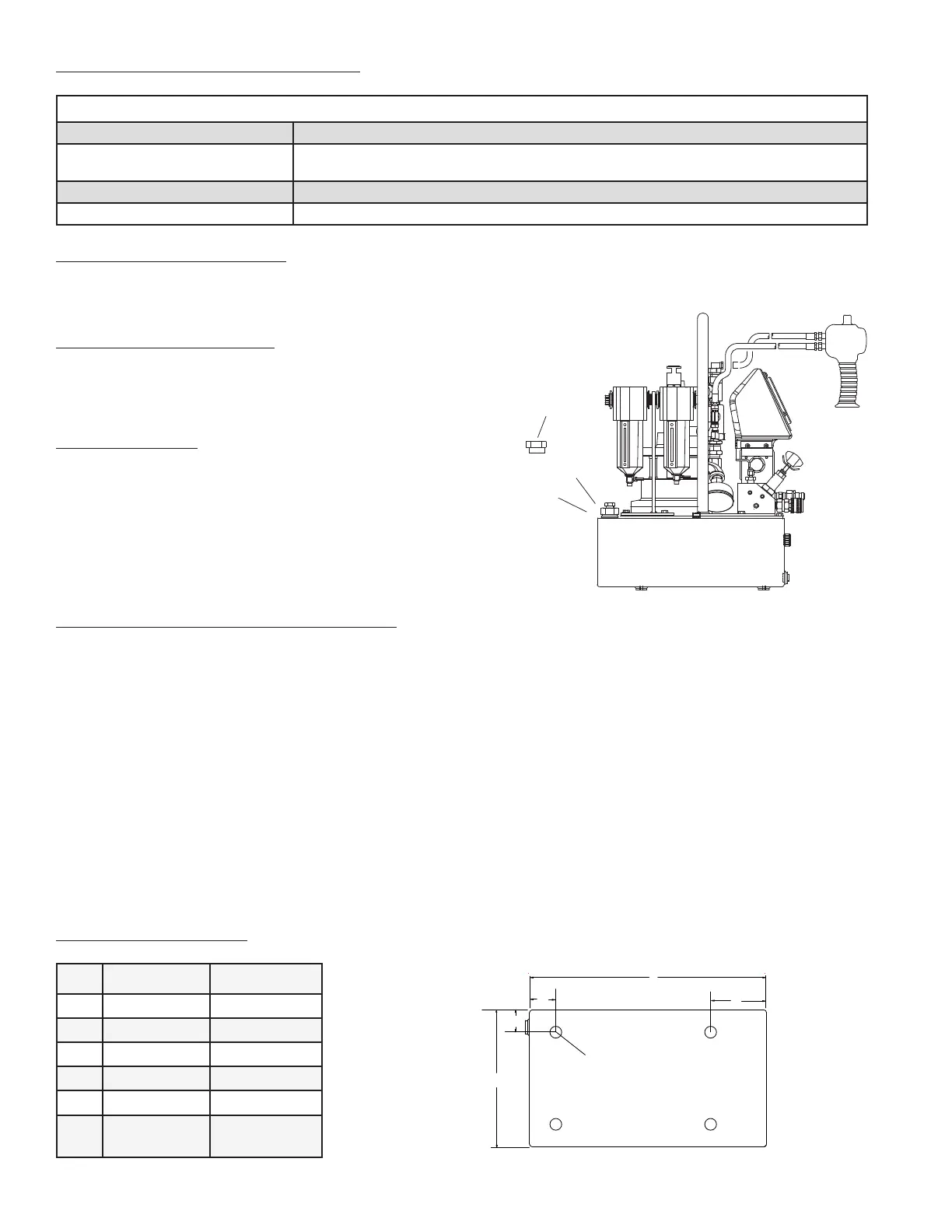

4.4 PUMP MOUNTING Refer to the chart for mounting dimensions to secure the pump to a xed surface.

1.5 gal.(6L) 2.5 gal.(10L)

A

15.13 17

B

3.68 4.75

C

1.57 2.37

D

1.43 1.93

E

8.75 9.75

F

1/4-20unc

(4 places)

1/4-20unc

(4 places)

A

B

C

D

E

F

Loading...

Loading...