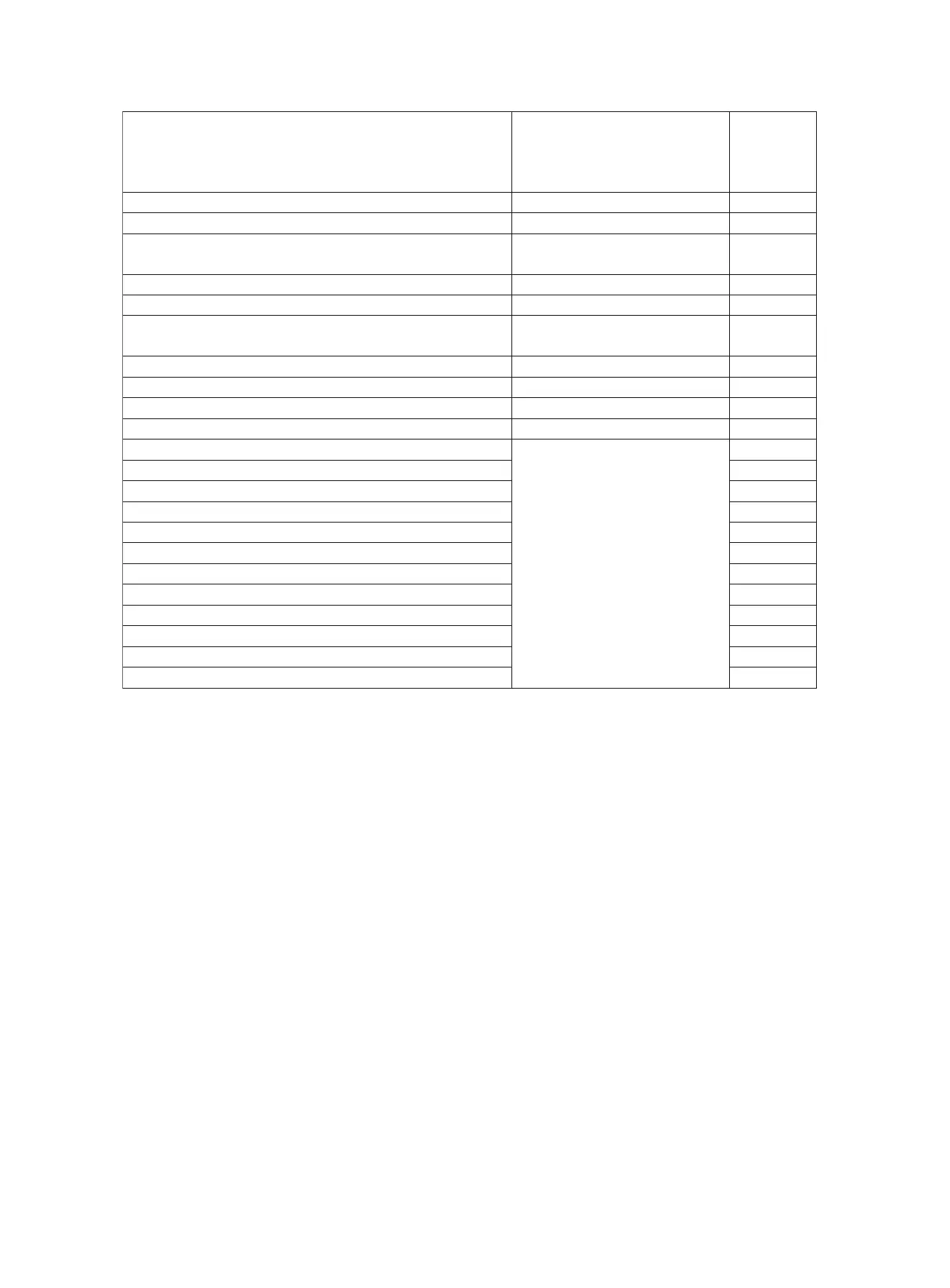

26

14/18K: 24/28K:

43 Communication failure with Unit A

● Ƽ ● ●

44 Communication failure with Unit B Ƽ Ƽ ● ●

45 Communication failure with Unit C ○ ○ Ƽ ●

46 Communication failure with Unit D ● ○ Ƽ ●

47 Unit A freeze protection Ƽ ○ Ƽ ●

48 Unit B freeze protection ○ ● Ƽ ●

49 Unit C freeze protection ● ● Ƽ ●

50 Unit D freeze protection Ƽ ● Ƽ ●

51 Unit A overheating prevention protection ○ Ƽ Ƽ ●

52 Unit B overheating prevention protection ● Ƽ Ƽ ●

53 Unit C overheating prevention protection Ƽ Ƽ Ƽ ●

54 Unit D overheating prevention protection

○

○

○

Ƽ

55 Unit A communication wire misconnection or expansion valve malfunction ● ○ ○ Ƽ

56 Unit B communication wire misconnection or expansion valve malfunction Ƽ

○

○

Ƽ

57 Unit C communication wire misconnection or expansion valve malfunction ○ ● ○ Ƽ

58 Unit D communication wire misconnection or expansion valve malfunction ● ● ○ Ƽ

Note: discharge the position in below pictures with discharge resistance after open the top cover and

check if the voltage is below 20V with universal meter, then begin to check.

1 IPM protection malfunction:

Main checking point:

● If the input voltage of the unit is within normal range?

● If the connection wire of compressor is connected well? Is it loose? If the connection sequence is correct?

● If the resistance of compressor coil is normal? If the isolation of compressor coil with copper pipe is good?

● If the unit is overloaded? If the heat radiation of the unit is good?

● If the refrigerant charge is suitable?

Flow chart:

9.3 Malfunction Checking and Elimination

Compressor overload protection

Viewing malfunction code

through remote controller within

200s; displayed directly on

nixietube after 200s

H3

PL noitcnuflam erawdraH hctam ton od tinu roodtuo dna tinu roodnI

EE noitcnuflam erawdraH pihc yromem fo noitcnuflaM

Wrong connection of communication wire or malfunction of

electronic expansion valve

Hardware malfunction

dn

Malfunction of complete units current detection Hardware malfunction U5

3L noitcnuflam erawdraH 1 naf roodtuo fo noitcetorp noitcnuflaM

Detection status of wrong connection of communication wire

or malfunction of electronic expansion valve

Operation status

dd

7E sutats noitarepO tcilfnoc edoM

oF sutats noitarepO edom gnilcycer tnaregirfeR

LA sutats noitarepO naf-X

1H sutats noitarepO edom gnitaeh ni nruter lio ro gnitsorfeD

Start failure of compressor

Viewing malfunction code

through remote controller within

200s; displayed directly on

nixietube after 200s

Lc

4E rosserpmoc fo noitcetorp erutarepmet egrahcsid hgiH

Overload protection E8

5E noitcetorp tnerrucrevo tinu elohW

5P noitcetorp tnerruc esahp rosserpmoC

Compressor desynchronizing H7

dL noitcetorp esrevni-esahp/gnikcal-esahp rosserpmoC

IPM modular protection H5

DC bus-bar low volt LP noitcetorp ega

HP noitcetorp egatlov hgih rab-sub CD

PFC protection HC

7U lamronba si evlav yaw-ruof ehT

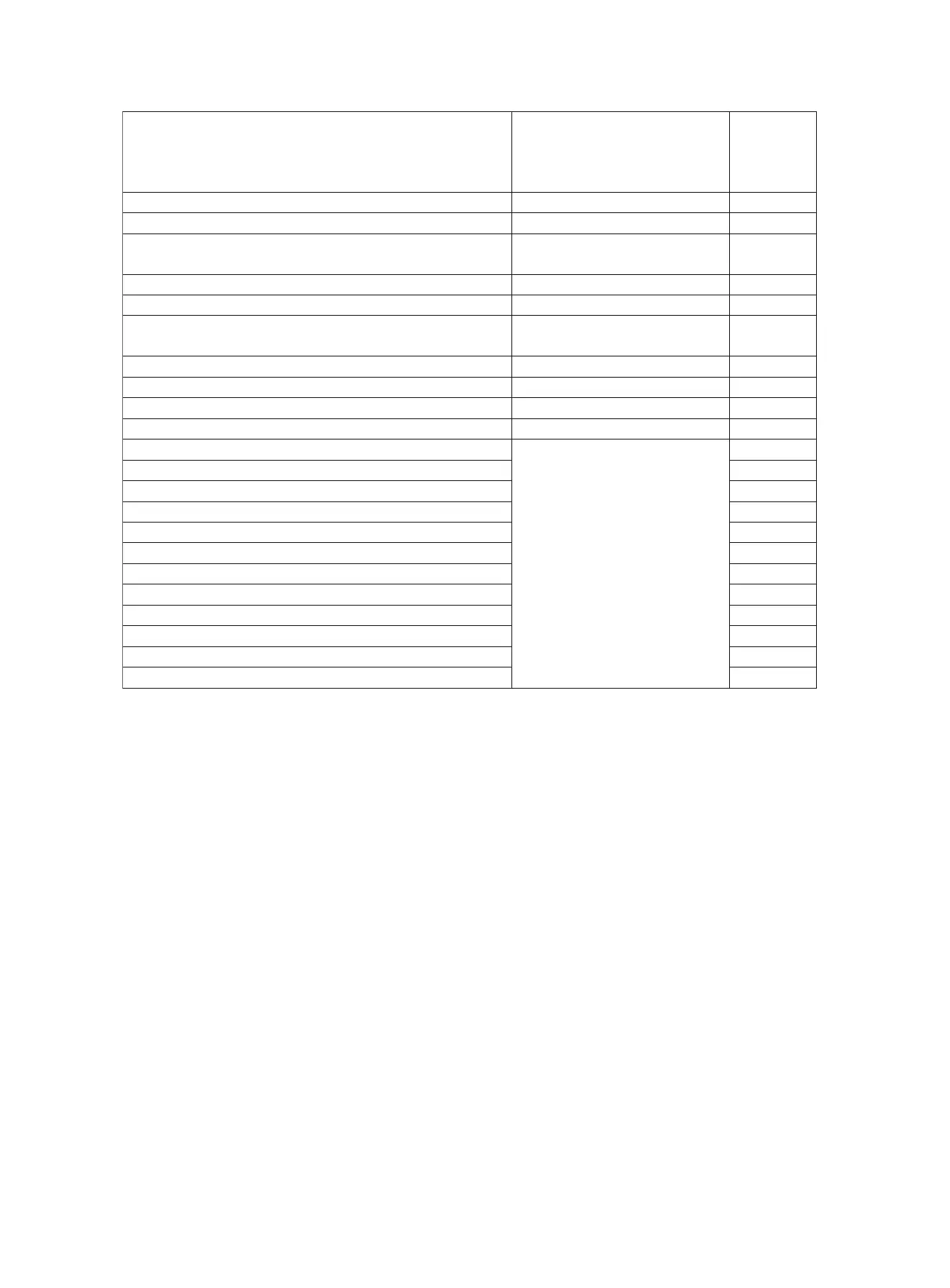

14/18K: 24/28K:

43 Communication failure with Unit A

● Ƽ ● ●

44 Communication failure with Unit B Ƽ Ƽ ● ●

45 Communication failure with Unit C ○ ○ Ƽ ●

46 Communication failure with Unit D ● ○ Ƽ ●

47 Unit A freeze protection Ƽ ○ Ƽ ●

48 Unit B freeze protection ○ ● Ƽ ●

49 Unit C freeze protection ● ● Ƽ ●

50 Unit D freeze protection Ƽ ● Ƽ ●

51 Unit A overheating prevention protection ○ Ƽ Ƽ ●

52 Unit B overheating prevention protection ● Ƽ Ƽ ●

53 Unit C overheating prevention protection Ƽ Ƽ Ƽ ●

54 Unit D overheating prevention protection

○

○

○

Ƽ

55 Unit A communication wire misconnection or expansion valve malfunction

●

○

○

Ƽ

56 Unit B communication wire misconnection or expansion valve malfunction Ƽ

○

○

Ƽ

57 Unit C communication wire misconnection or expansion valve malfunction ○ ● ○ Ƽ

58 Unit D communication wire misconnection or expansion valve malfunction ● ● ○ Ƽ

Note: discharge the position in below pictures with discharge resistance after open the top cover and

check if the voltage is below 20V with universal meter, then begin to check.

1 IPM protection malfunction:

Main checking point:

● If the input voltage of the unit is within normal range?

● If the connection wire of compressor is connected well? Is it loose? If the connection sequence is correct?

● If the resistance of compressor coil is normal? If the isolation of compressor coil with copper pipe is good?

● If the unit is overloaded? If the heat radiation of the unit is good?

● If the refrigerant charge is suitable?

Loading...

Loading...