HOOK

(SEWING)

ADJUSTMENTS

To

See

if

the

Hooks

are

in

Correct

Time.

Remove

the

slides

and

throat

plate and

turn

the balance wheel toward you until

the

needle

bar

has

passed

its

lowest

position

and

risen

so

that

the

lower

mark

on

it

is

even

with

the

underside

of

the

needle

bar

bushing.

If

in

correct

time,

the

point

of

each

hook

will

be

at

the

center of each needle and inch above the eye; if not, loosen the

screws

in

the

bevel

gear

on

the

shaft

under

the

hook

and

turn

the

gear

forward

or

backward

slightly

until

the

hook

is in

time

as

instructed

above,

then

retighten

the

screws.

Be sure

that

the needle guard on the hook washer (see Fig.

11)

does

not

deflect

the

needle.

If

the

hook

is

too

far

from

or

too near the needle, loosen hook saddle screws (bb, see Fig. 2)

just

enough to permit the saddle to be driven with light blows

to

the

position

desired,

then

retighten

the

screws.

Fig.

12

Bobbin

Case

Washer

(Cloth)

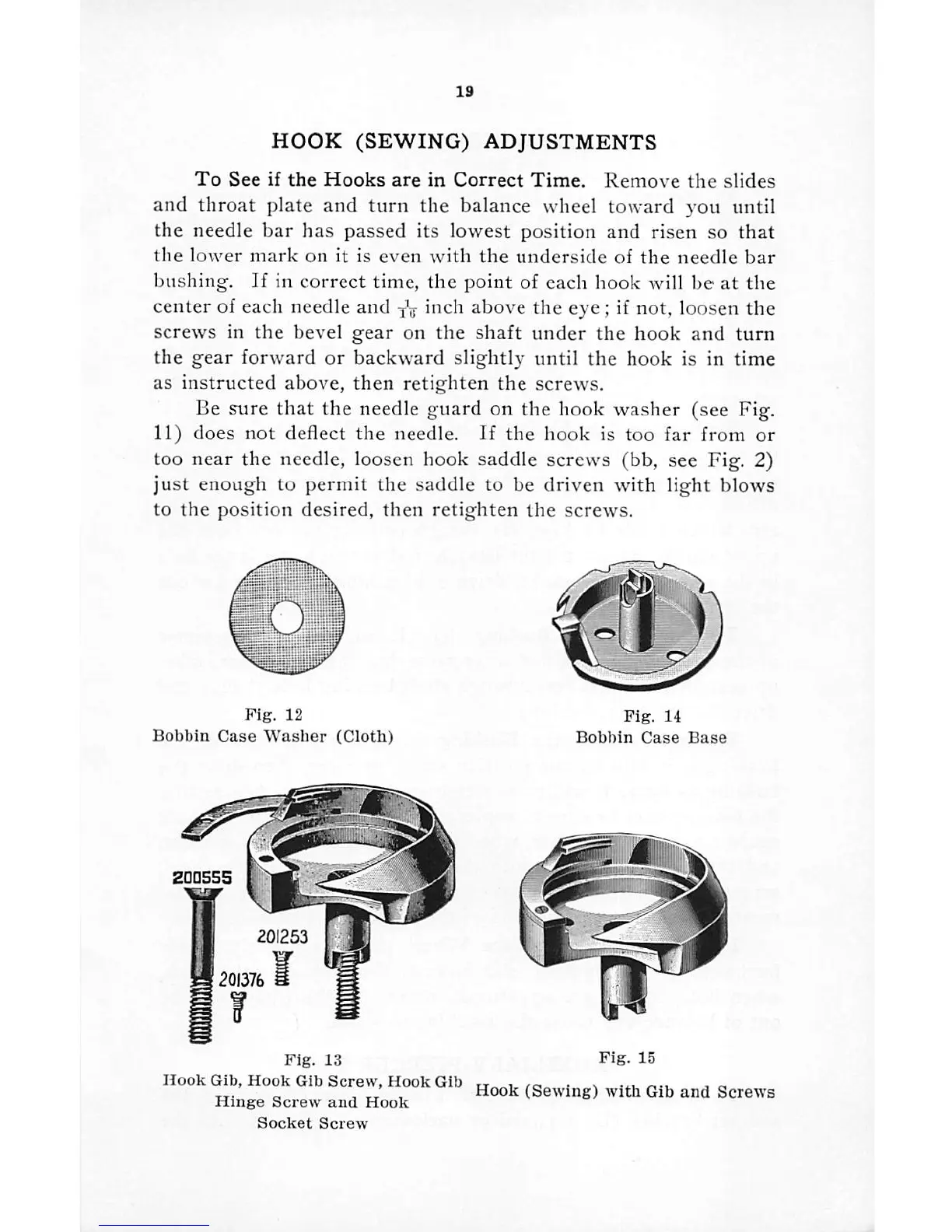

200555

201253

Fig.

13

Hook

Gib,

Hook

Gib

Screw,

Hook

Gib

Hinge

Screw

and

Hook

Socket

Screw

Fig.

14

Bobbin

Case

Base

Fig.

15

Hook

(Sewing)

with

Gib

and

Screws

Loading...

Loading...