SPEED

Maximum

speed for Machines 262-1,

262-21

is 6000

stitches

per minute.

Maximum

speed for Machines 262-2, 262-22 is 5500

stitches

per minute.

Maximum

speed for Machines 262-3, 262-20, 262-23,

262-24, 262-25, 262-31 is 5000

stitches

per minute.

Maximum

speed

recommended for Machine 262-32 is

4000 revolutions per minute.

it is

advisable

to

operate

new machines at a speed

of

500

stitches

less

than

maximum, for

the

first

100

hours

of

operation.

Maximum

efficient speed is dependent upon the

nature of the operation, the ability of the. operator and

the type of thread and moterial in

use.

FILL

TO

HIGH

MARK

feifiisg®:

fa

1

GASKET

RESERVOIR

. -

HISH

-

.-LOW ADDOIL-

FELT

PAD

Fig.

2.

Modiine

Base

and

Oil

Reservoir

SHOULD

SHOW

STEADY

FLOW

OF

OIL

Fig.

3.

Oil

Flow

Window

\\\\\

INSTALLATION

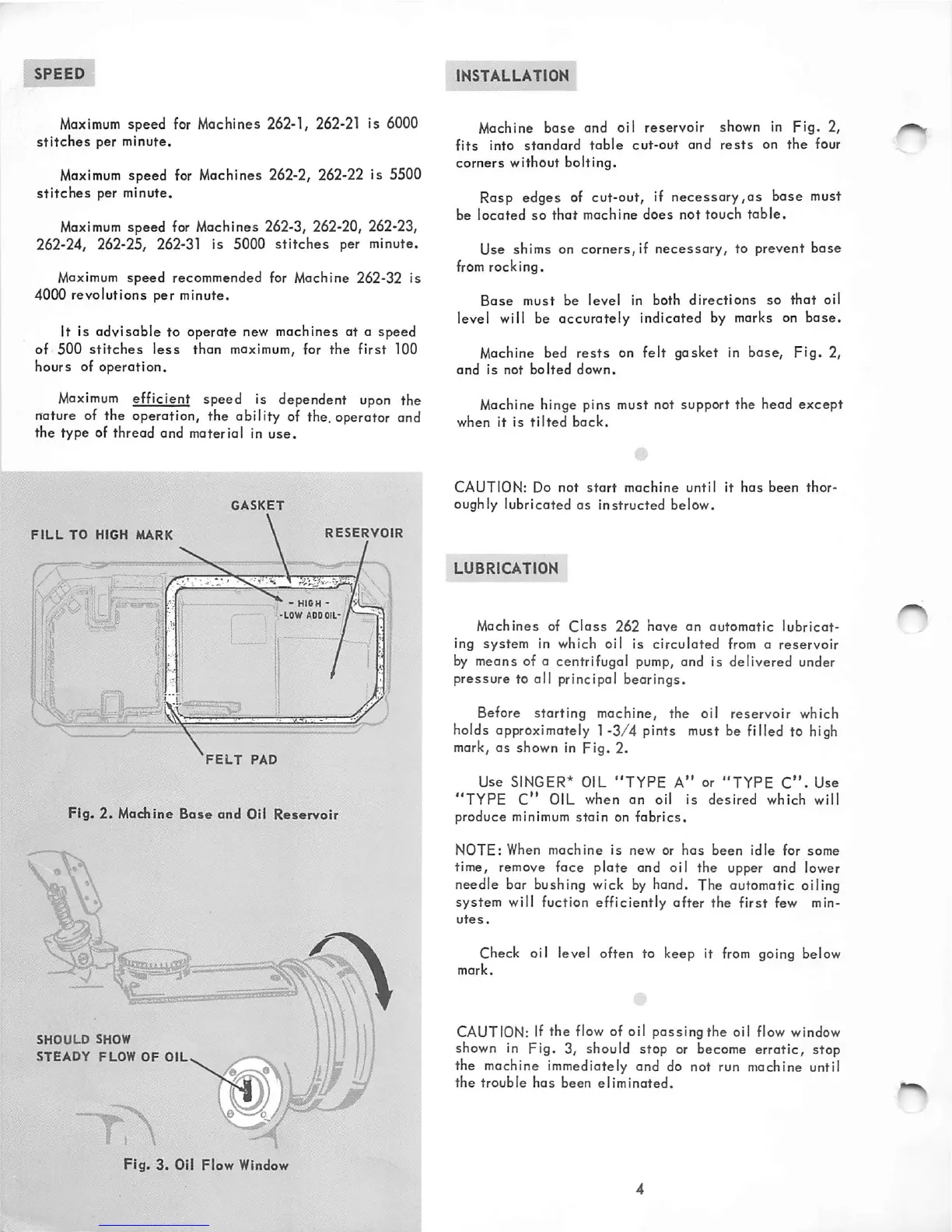

Machine

base

and oil reservoir shown in

Fig.

2,

fits

into

standard

table

cut-out

and

rests

on

the

four

corners without bolting.

Rasp edges of cut-out, if

necessary,as

base must

be

located

so

that

machine

does

not

touch

table.

Use shims on corners, if necessary, to prevent base

from

rocking.

Base

must

be

level

In

both

directions

so

that

oil

level will be accurately indicoted by marks on base.

Machine bed

rests

on

felt

gasket

in

base.

Fig.

2,

and

is

not

bolted

down.

Machine hinge pins must not support the head except

when

it

is

tilted

bock.

CAUTION:

Do

not

start

machine

until

it

has

been

thor

oughly lubricated as instructed below.

LUBRICATION

Machines

of

Class

262

have

an

automatic

lubricat

ing

system

in which oil is

circulated

from a

reservoir

by means of a centrifugal pump, and is delivered under

pressure to all principal bearings.

Before starting machine, the oil reservoir which

holds approximately 1

-3/4

pints must be filled to high

mark, as shown in Fig. 2.

Use

SINGER*

OIL

"TYPE

A"

or

"TYPE

C".

Use

"TYPE

C"

OIL

when

an oil is

desired

which

will

produce minimum

stain

on

fabrics.

NOTE:

When

machine

is

new

or

has

been

idle

for

some

time, remove face

plate

and oil the upper and lower

needle bar bushing wick by hand. The automatic oiling

system will fuction efficiently after the first few min

utes.

Check oil level often to keep it

from

going below

mark.

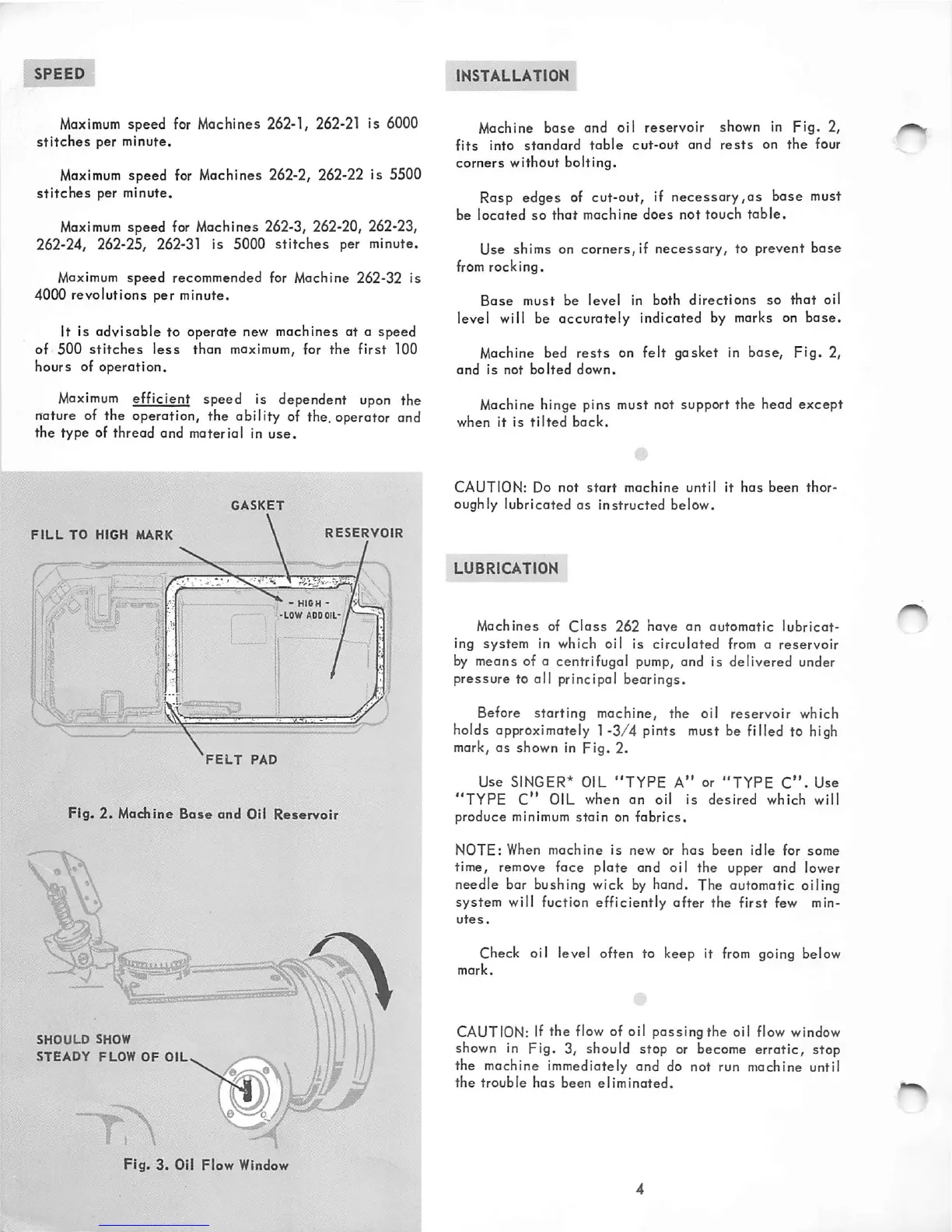

CAUTION:

If the flow of oil passing the oil flow window

shown in Fig. 3, should stop or become erratic, stop

the machine immediately and do not run machine until

the

trouble

has

been

eliminated.

Loading...

Loading...