•NEEDLES

Machines 262-1, 262-2, 262-20, 262-21 and 262-22:

Use SINGER* Needles, Catalog 2793 (149x525).

Machines 262-3, 262-23, 262-24, 262-25, 262-31 and

262-32:

Use SINGER

Needles,

Catalog 4107 (62x45).

Machine

262-32:

For heavier weight denim, use Catalog 3670 (149x4).

TO

SET

THE

NEEDLE

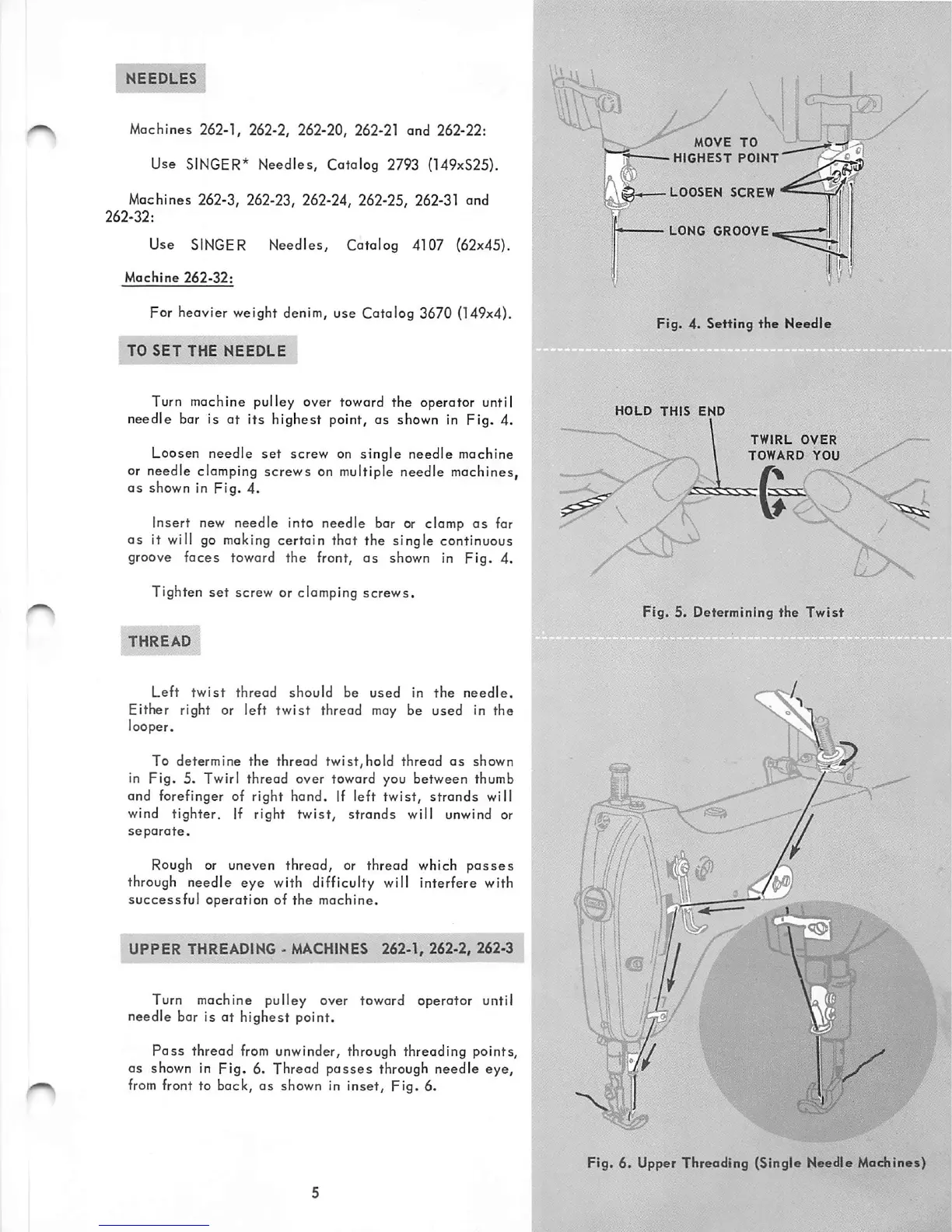

Turn machine pulley over toward the operator until

needle bar is at its highest point, as shown in Fig. 4.

Loosen

needle

set

screw on

single

needle

machine

or needle clamping screws on multiple needle machines,

as

shown in Fig. 4.

Insert new needle into needle bar or clamp as far

as it will go making certain that the single continuous

groove faces toward the front, as shown in Fig. 4.

Tighten

set

screw or clamping screws.

THREAD

Left

twist

thread

should

be

used

in

the

needle.

^

Either right or left twist threod may be used in the

looper.

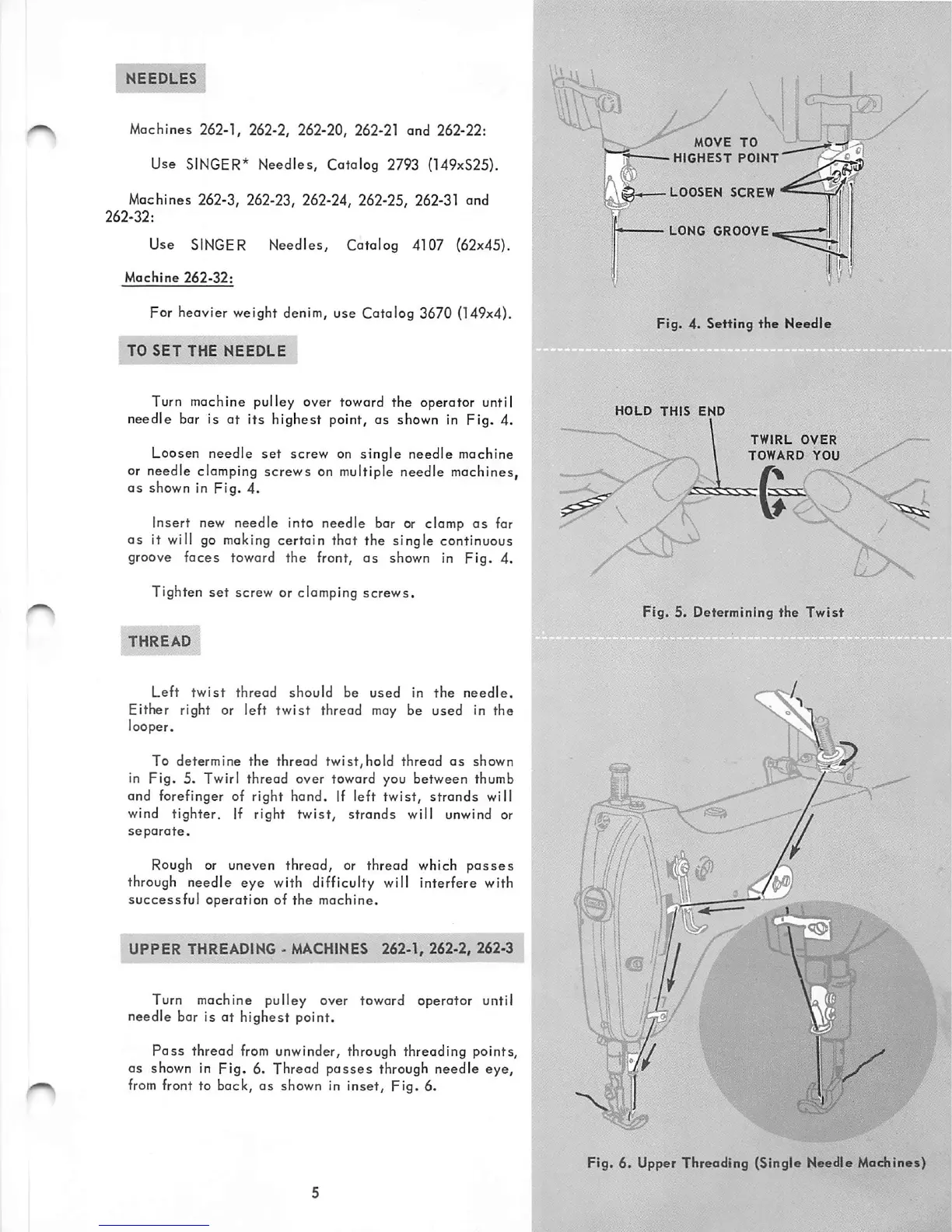

To

determine

the

thread

twist,hold

thread

as

shown

in Fig. 5. Twirl thread over toward you between thumb

and forefinger of right hand. If left

twist,

strands

will

wind tighter. If right

twist,

strands will unwind or

separate.

Rough or uneven thread, or thread which

passes

through needle eye with difficulty will interfere with

successful

operation of the machine.

UPPER

THREADING - MACHINES 262-1, 262-2, 262-3

Turn machine pulley over toward operator until

needle bar is at highest point.

Pass

thread

from

unwinder, through threading points,

as shown in Fig. 6. Thread

passes

through needle eye,

from front to bock, as shown in

inset.

Fig.

6.

MOVE

TO

•

HIGHEST

POINT

LOOSEN

SCREW

LONG

GROOVE-

Fig. 4. Setting

the

Needle

HOLD

THIS

END

TWIRL

OVER

TOWARD

YOU

).

Fig.

5. Determining

the

T\

m

m

dm

Fig.

6.

Upper Threading (Single Needle Machines)

Loading...

Loading...