/

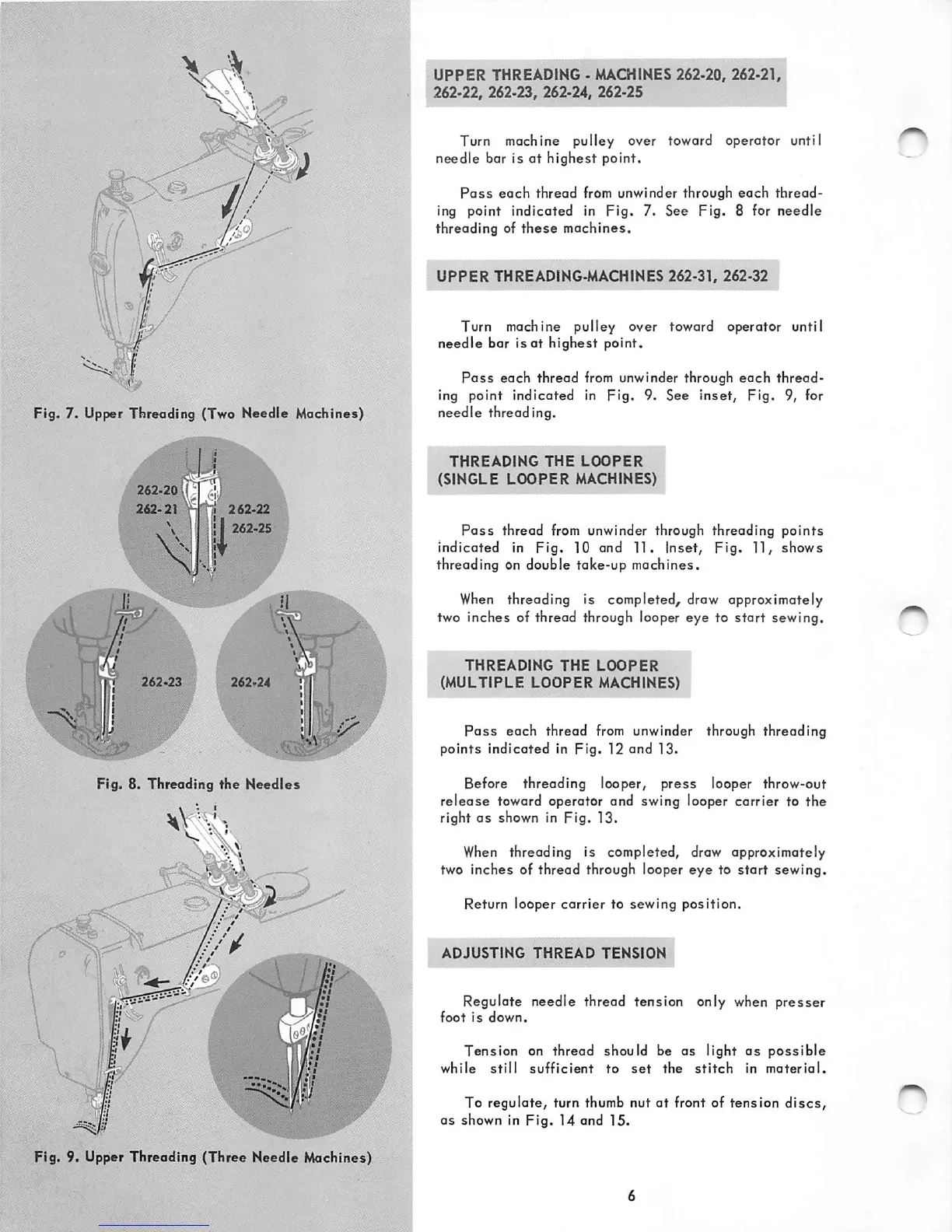

Fig. 7. Upper Threoding (Two Needle Machines)

26^20l(.

262-21^

fi

262^22

i

11

262-25

4262.2.1

262-24

Fig. 8. Threoding

the

Needles

%

• '

/•

•^ / • /

" r ^

!

Iff/

:w

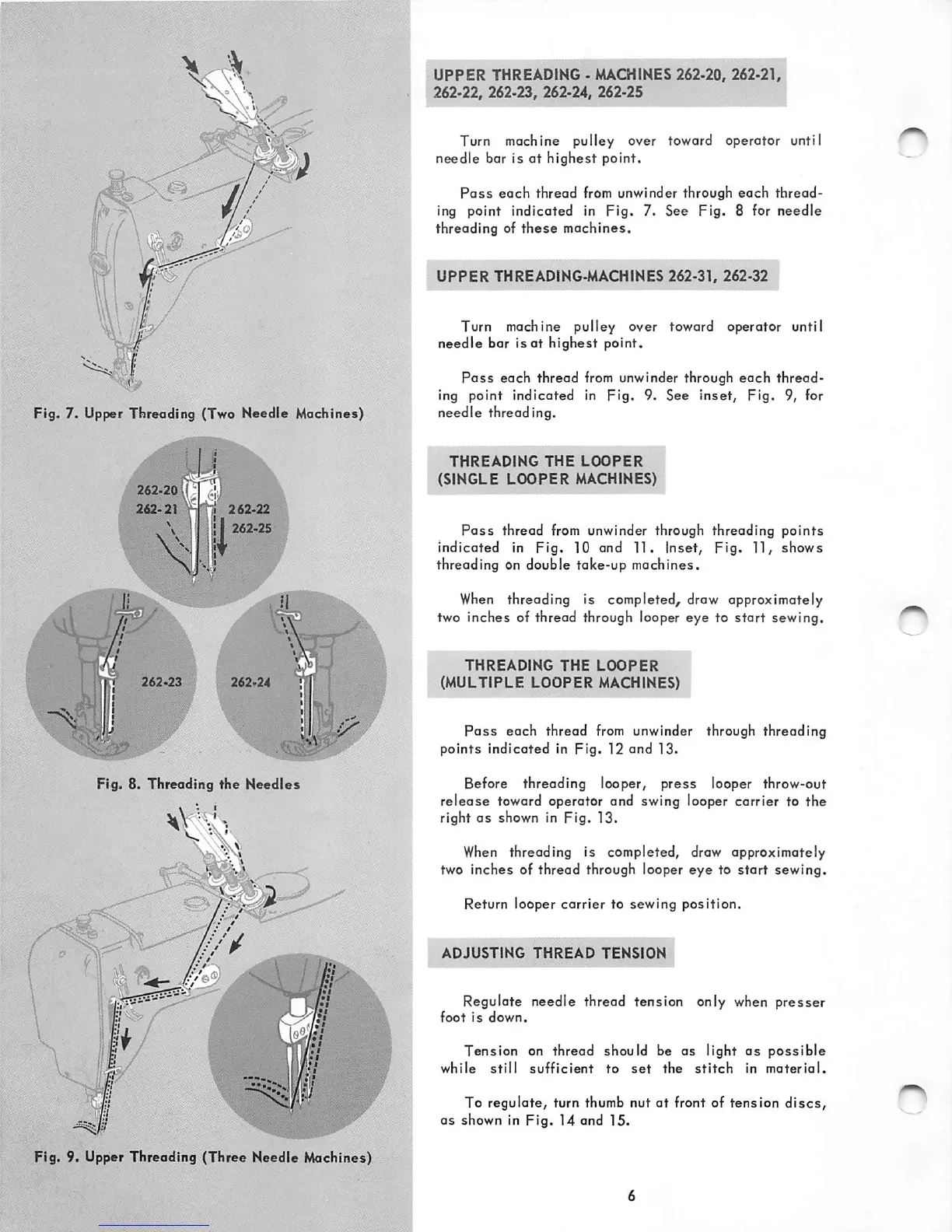

Fig. 9. Upper Threading (Three Needle Machines)

UPPER

THREADING • MACHINES 262.20, 262-21,

262-22, 262.23, 262-24, 262-25

Turn machine pulley over toward operator until

needle

bar is

at

highest

point.

Pass

each

thread from unwinder through

each

thread

ing point indicated in

Fig.

7. See

Fig.

8 for

needle

threading of

these

machines.

UPPER

THREADING-MACHINES

262-31,

262-32

Turn machine pulley over toward operator until

needle

bar is

at

highest

point.

Pass

each

thread from unwinder through

each

thread

ing point indicated in

Fig.

9. See Inset,

Fig.

9, for

needle threading.

THREADING

THE

LOOPER

(SINGLE

LOOPER

MACHINES)

Pass

thread from unwinder through threading

points

indicated in

Fig.

10 and 11. Inset,

Fig.

11, shows

threading on double take-up machines.

When

threading Is completed, draw approximately

two inches of thread through looper eye to

start

sewing.

THREADING

THE

LOOPER

(MULTIPLE

LOOPER

MACHINES)

Pass

each thread

from

unwinder through threading

points

indicated

in

Fig.

12

and

13.

Before threading looper,

press

looper throw-out

release

toward operator and swing looper carrier to the

right

as

shown In Fig. 13.

When

threading Is completed, draw approximately

two inches of thread through looper

eye

to

start

sewing.

Return looper carrier to sewing position.

ADJUSTING

THREAD

TENSION

Regulate needle thread tension only when

presser

foot

is

down.

Tension

on thread should be

as

light

as

possible

while

still

sufficient

to

set

the

stitch

in

material.

To regulate, turn thumb nut

at

front of

tension

discs,

as shown in

Fig.

14 and 15.

Loading...

Loading...