:

I

I

I

------~--------~-------~-------~---------~---------------------------------------------~--

1:

~~~~)Sl~

MOTOR AND BELT

----------------------------------------------'

1.

~-8~Jlffijl

1/2

,'lffi}J

(

§.X

400

K£

)

, 3

*13

2 ~ M * v

~Blm

0

2.~•m~2~•©•~~u8lm~w~

• 8l m

tnu

~

lf:l/11\

~

~~ ~w

~tm-

~

~

0

ID

~

~~

92

~~

~w

~

r.c

=

1.m*'iffi~~~

2

.

~fli~5i

3.~

4

.*l~e

~~~®a~~

,

~~~mm~~5~~Q

P~

,

~~~

,

&2~U~~

o

Clll24)

-25-

I

I

I

1. Clutch Motor, 1/2 HP (400W), 3 phase, 2 !

pole M type V belt. !

2.

When installing the motor, the center line

of

both motor's and machine's pulley

must

be aligned with each other.

THREADING

I

I

I

I

i

!

i

I

""l

l

_____

J

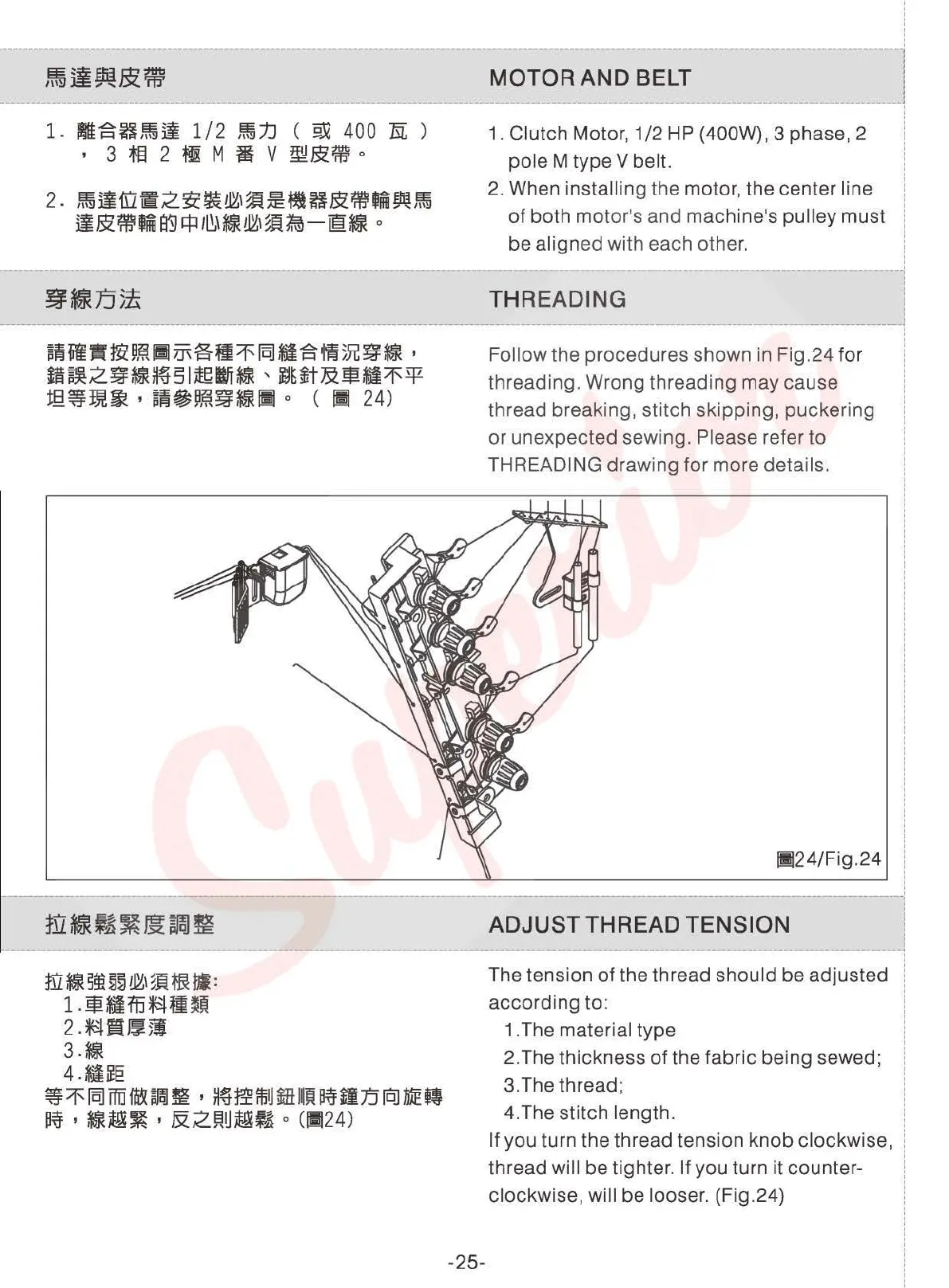

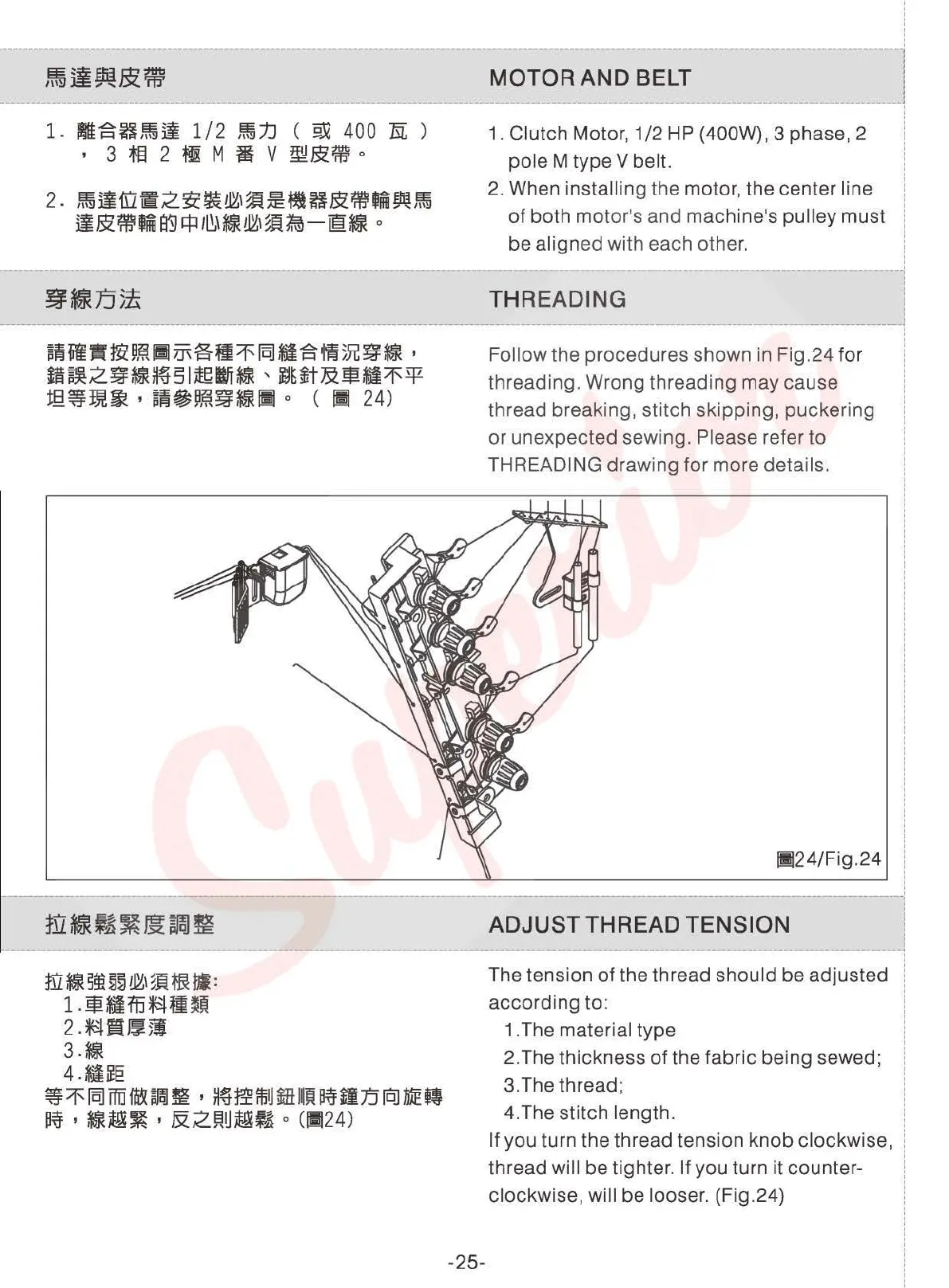

Follow the procedures shown in Fig.24 for

threading. Wrong threading may cause

thread breaking, stitch skipping, puckering

or

unexpected sewing. Please refer

to

THREADING drawing for more details.

I

I

I

I

I

I

I

I

!

!ll24/Fig

.24

~

I

I

----~-

·i

ADJUST THREAD

TENSION

I

j

·

--·----!

The tension of the thread should be adjusted I

according to:

1.The

material type

2.The thickness

of

the fabric being sewed;

3.The thread;

4.The stitch

length.

i

!

i

!

I

I

I

I

i

!

i

I

If you turn the thread tension knob clockwise, i

I

thread will be tighter. If you turn it counter- !

clockwise, will be looser. (Fig.24) i

i

!

i

!

I

I

From the library of: Superior Sewing Machine & Supply LLC

Loading...

Loading...