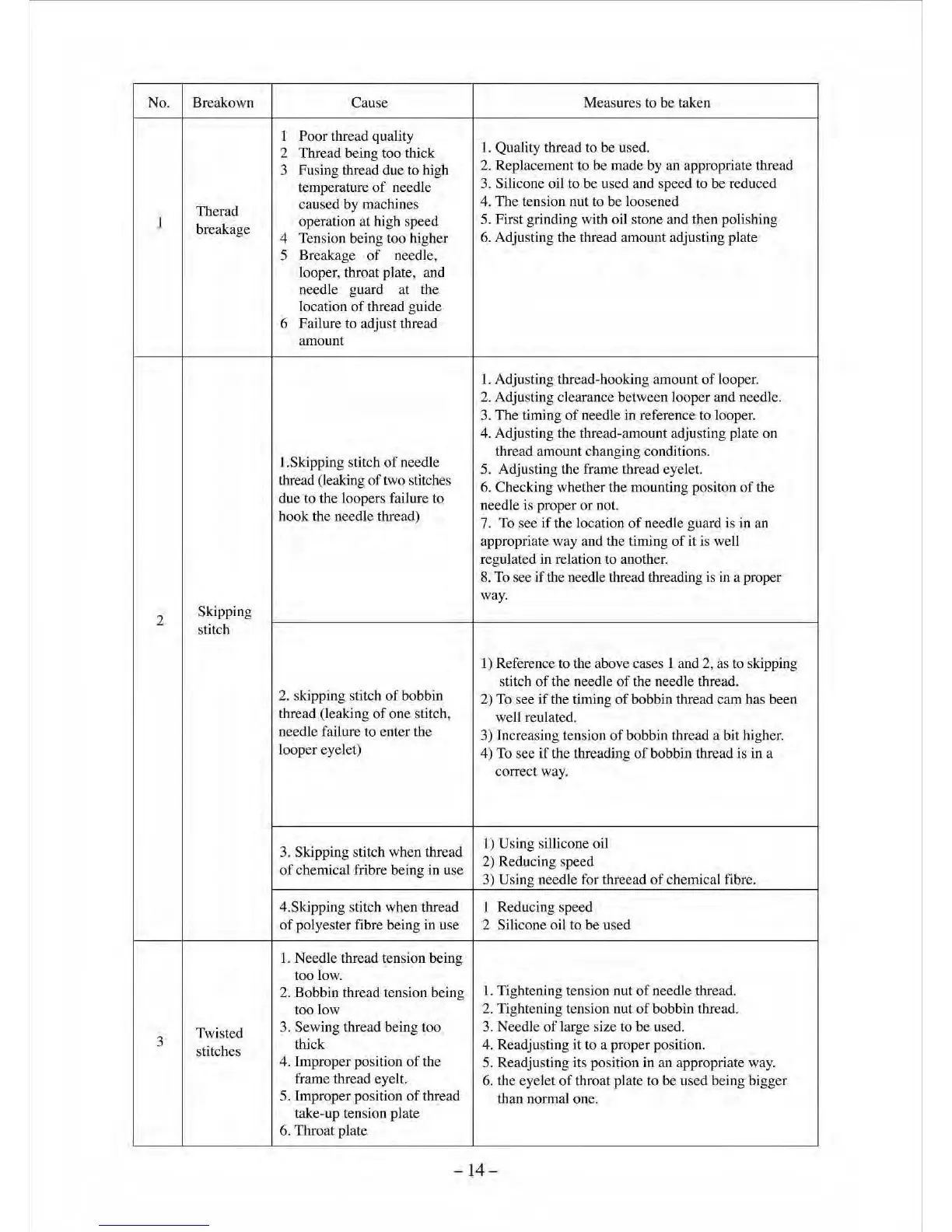

No.

2

3

Break

ow

n

Therad

br

ea

kage

Skipping

stitch

Twist

ed

stitches

Cause

I Poor thread quality

2 Thread being too

thi

ck

3 Fusing thread due to

hi

gh

temper

at

ure

of

needle

caused by machin

es

operation at high speed

4 Tension being too

hi

gher

5

Br

eakage

of

needle,

lo

oper, throat

pl

ate, and

needle gua

rd

at the

location

of

thread guide

6 Failure to adjust thread

amount

!.Skipping stitch

of

needle

thread (leaking

of

two stitches

due to the loopers

fa

ilure to

hook the

need1

e thread)

2. skipping stitch

of

bobbin

thread (leaking

of

one stitch,

needle failure to ent

er

the

looper eyelet)

3.

Skipping stitch when thread

of

chemical fribre be

in

g

in

use

4.Skipping stitch when thread

of

polyester fibre being in use

1. Needle thread tension being

too low.

2.

Bobb

in thread tension being

too low

3.

Sewing thread being too

thi

ck

4. Improp

er

po

sition

of

the

frame thread

ey

elt.

S.lmproper

position

of

thread

take-up tension plate

6. Throat plate

Measures to be taken

1.

Quality thread to be used.

2.

R

ep

lacement t.o be made

by

an appropriate thread

3.

Silicone oil to be used a

nd

speed to be reduced

4. The tension nut to be loosen

ed

5.

Fir

st grinding with oil stone and then polishing

6. Adjusting the thread amount adjusting plate

1.

Adjusting thread-hooking amount

of

looper.

2.

Adjusting clearance

bet

ween looper and n

ee

dle.

3.

The

timing

of

needle

in

reference to looper.

4. Adjusting the thread-amount adjusting

pl

ate on

thr

ead

amount chang

in

g conditions.

5. Adjusting the frame thread eyelet.

6.

Checking whether the mounting positon

of

the

needle is proper

or

not.

7.

To

see if

th

e location

of

needle guard is

in

an

appropriate way and

the timing

of

it is weU

regulated in relation to another.

8.

To see

if

th

e needle thread threading is

in

a proper

way.

1) Reference to the above cases I and 2, as to skipping

stitch

of

the needle

of

the needle thread.

2) To see

if

th

e timing

of

bobbin thread cam has been

we

ll

reulated.

3) Increas

in

g tension

of

bobbin thread a

bi

t

hi

ghe

r.

4) To see if the threading

of

bobbin thread is

in

a

correct way.

1)

Using sillicone oil

2) Reduc

in

g speed

3)

Using needle for threead

of

chemical fibre.

I Reducing speed

2 Silicone oil to be used

l. Tightening tension nut

of

needle thread.

2. Tightening tension nut

of

bobbin thr

ea

d.

3.

Needle of large size to be used.

4. Read

ju

sting

it

to a proper position.

5. Readjusting its position

in

an appropriate way.

6.

the eyelet

of

thr

oa

t plate to be used be

ing

bi

gger

than normal on

e.

-14-

Loading...

Loading...