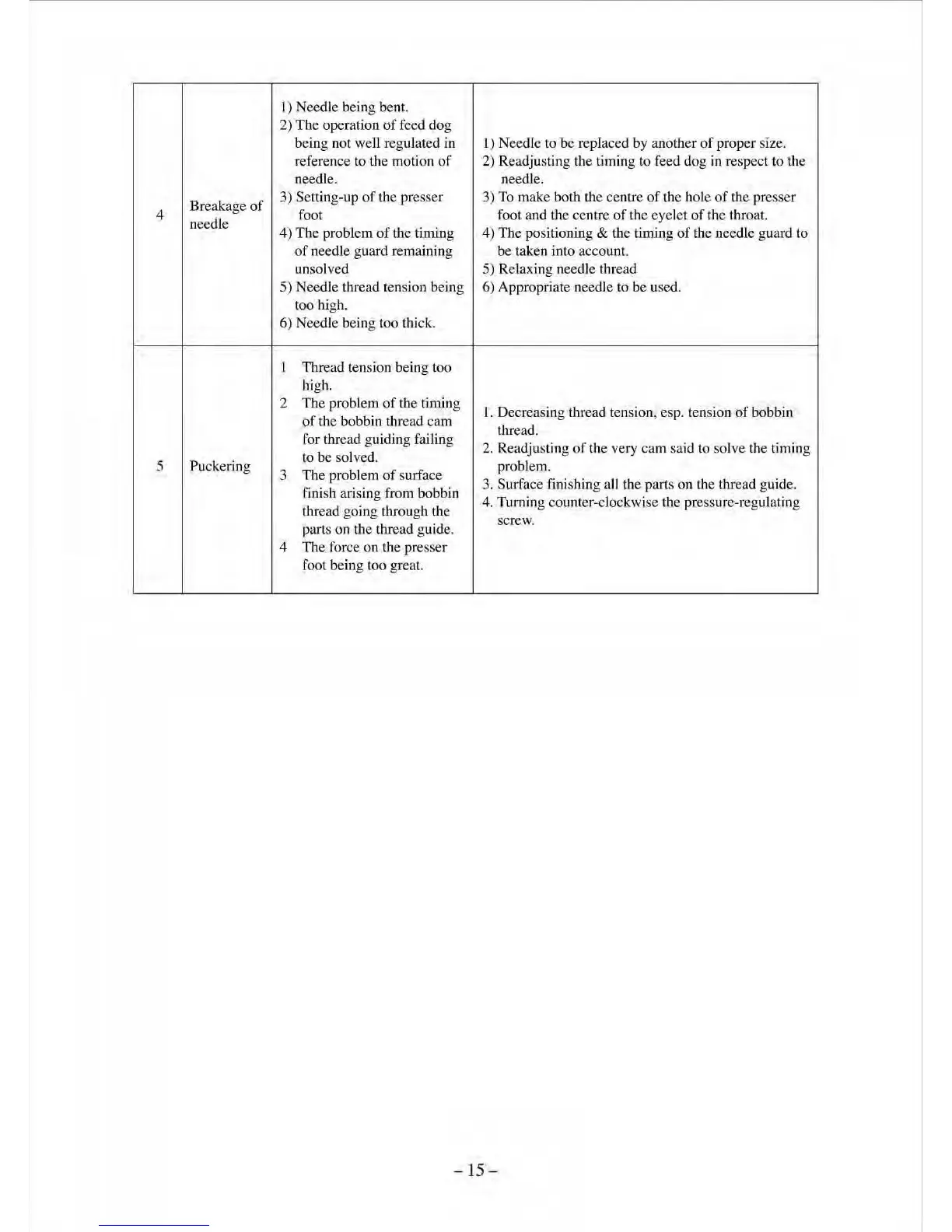

I) Needle being bent.

2) The op

er

ation

of

feed d

og

being n

ot

well regulated in 1) Needle to

be

r

ep

laced by another

of

proper size.

reference to the motion

of

2) Readjusting the timing to feed

dog

in

r

es

pect to the

needle.

needle.

Breakage

of

3) Setting-up

of

the pres

se

r 3) To make both the centre

of

the hole

of

the presser

4

n

ee

dle

foot foot and the

ce

ntre of the eyel

et

of

the throat.

4) The problem

of

the timing 4) The positioning & the timing

of

the needle gua

rd

to

of

needle guard remaining be taken into account.

un

solved 5) Relax

in

g needle thread

5) Needle thread tension being 6) Appropriate nee

dl

e to be used.

too high.

6) Needle being too thi

ck

.

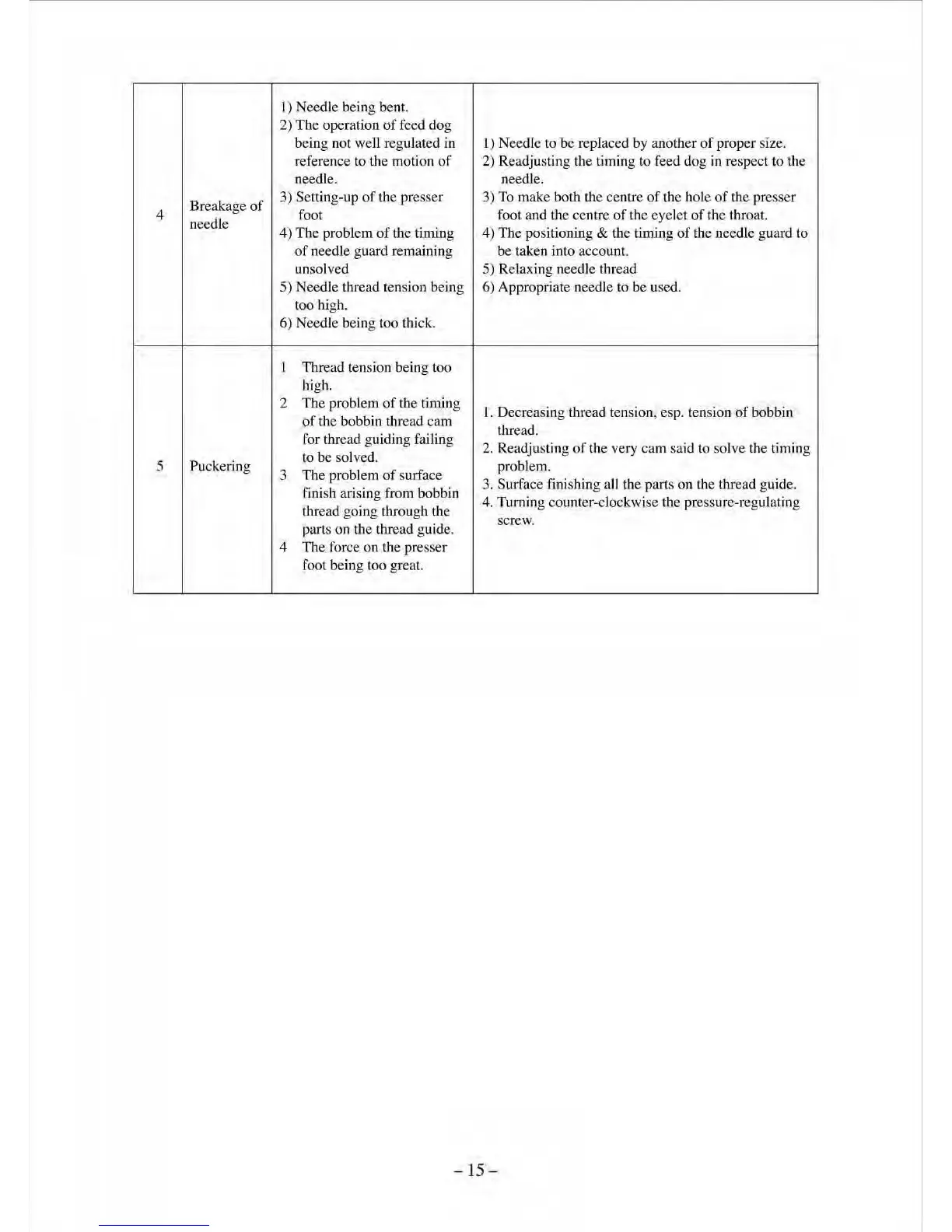

L

Thr

ead tension being too

high.

2

The problem

of

the timing

l . Decreas

in

g thread tension, esp. tension

of

bobbin

of

the bobbin thread cam

for thread guiding failing

thread.

to be solved.

2.

Readjosting of the very cam sa

id

to solve

th

e timing

5 Puckering

3 The problem

of

surface

problem.

finish arising from bobbin

3. Surface finishing all the parts on

th

e thread guide.

thread going through the

4. Thming

co

unter-clockwise the pressure-regulating

parts on

th

e thr

ea

d gui

de

.

screw.

4 The force on the presser

foot being too great.

-15-

Loading...

Loading...