- Code 08: Delay in the EC alarm detection.

Indicate the number of seconds during which

conductivity must be at an alarm level before its

activation. The value must be between 0 and

999.

- Code 09: Delay in the pH alarm detection.

Indicate the number of seconds during which

pH must be at an alarm level before its

activation. The value must be between 0 and

999.

- Code 10: Pre-agitation. Indicate the number of

seconds during which the agitator must be

working before injection is started. The value

must be between 0 and 250.

- Code 11: Agitator working. Indicate the number

of seconds the agitator must be working in the

agitation cycles, which take place during the

fertilisation. The value must be between 0 and

250.

- Code 12: Agitator at stop. Indicate the number

of seconds the agitator must be at stop in the

agitation cycles, which take place during the

fertilisation. The value must be between 0 and

250.

- Code 13: Alarm working. Indicate the number of

seconds the alarm must be working in the cycle

of alarm signal. The value must be between 0

and 250.

- Code 14: Alarm at stop. Indicate the number of

seconds the alarm must be at stop in the cycle

of alarm signal. The value must be between 0

and 250.

11. CALIBRATION

In the configuration of the user, codes from 00

to 03 are used to calibrate sensors. On entering in

everyone of the codes, the code and value which is

expected from the sensor appears for a few

seconds. After these seconds, the screen blinks and

displays the reading, which is being obtained from

the sensor. If the reading is stable enough and

similar to the desired one, the screen stops blinking,

indicating that the sensor has been calibrated. If you

press the “+” and “-“ keys simultaneously the unit is

forced to accept the value which is displayed at this

moment.

If the calibration of sensor is not to be done,

press the “C” key during the initial seconds or press

the “C” key until the code changes, when the screen

is blinking.

In order to have a good calibration, the sensor

and the liquid have to be as close as possible to

25ºC degrees. Then, the liquid value and the

automatic compensation that the sensor have will be

correct. If the irrigation water is cooler than 25ºC the

sensor it should be taken out for several minutes

because the sensor has and inertia to the

temperature changes.

The calibration codes go in pairs. So, codes 00

and 01 are used to calibrate the conductivity sensor,

while codes 02 and 03 correspond to the calibration

of the pH sensor. If a suitable calibration is not done

in the first code, the second one does not appear.

So, to do a valid calibration of the sensor, it is

necessary to do the two codes, which correspond to

the sensor correctly.

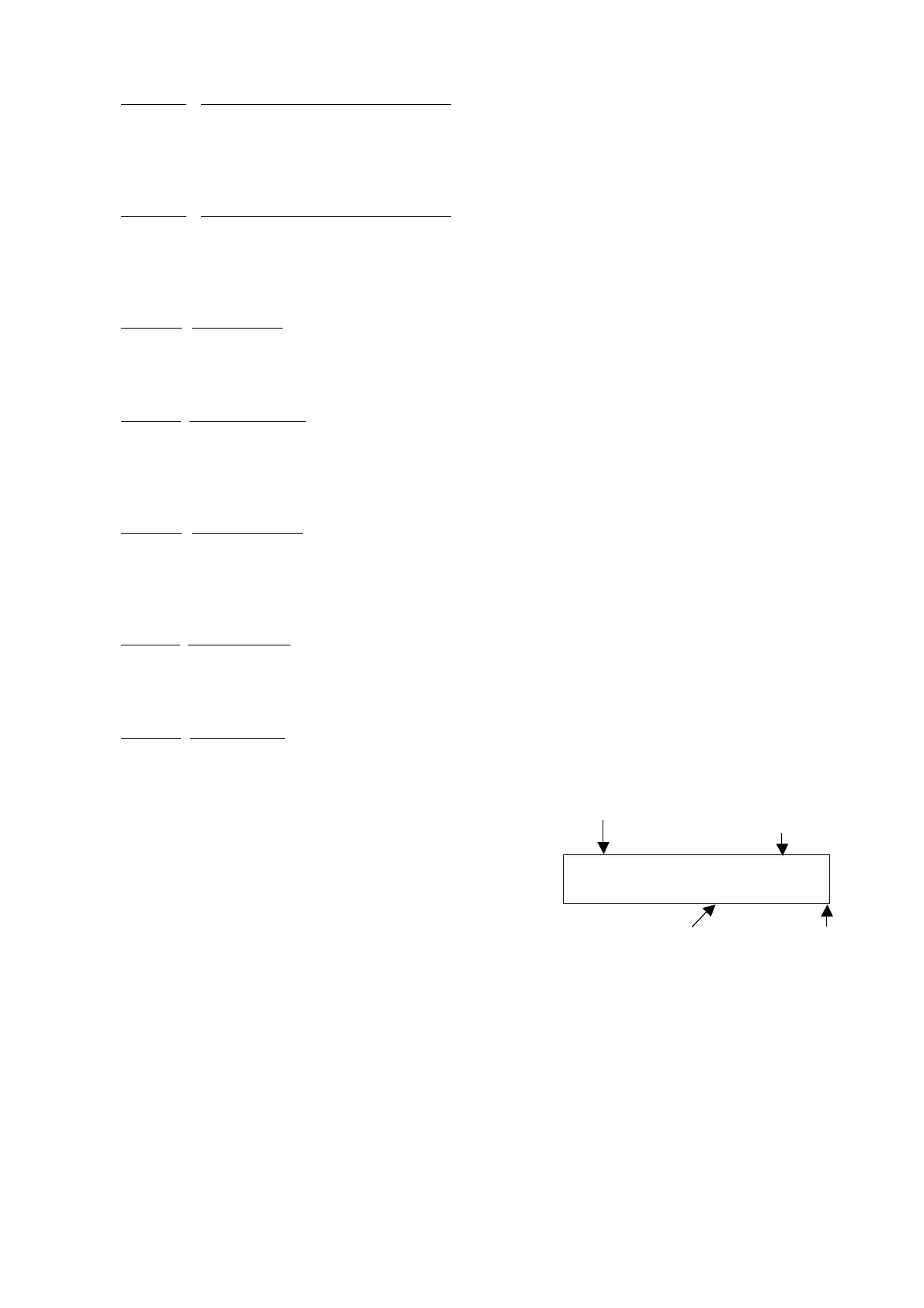

12. BREAKDOWNS

When the unit detects a breakdown, because a

non desired level of conductivity or pH has been

reached or because input 4 has been activated, the

programme stops automatically and injection also

stops. The screen displays the consultation code C0

and the information about the reason of the

breakdown in a blinking way. The programme will

not be started again until, the breakdown is not

deactivated by pressing the “C” key.

Option code Origin of the alarm

(EC, PH, E4)

C0

A

1

P

H

_

Indicator of the

alarm and nº of

programme

Type of alarm

(low, a dash below,

high, a dash above)

Loading...

Loading...