13

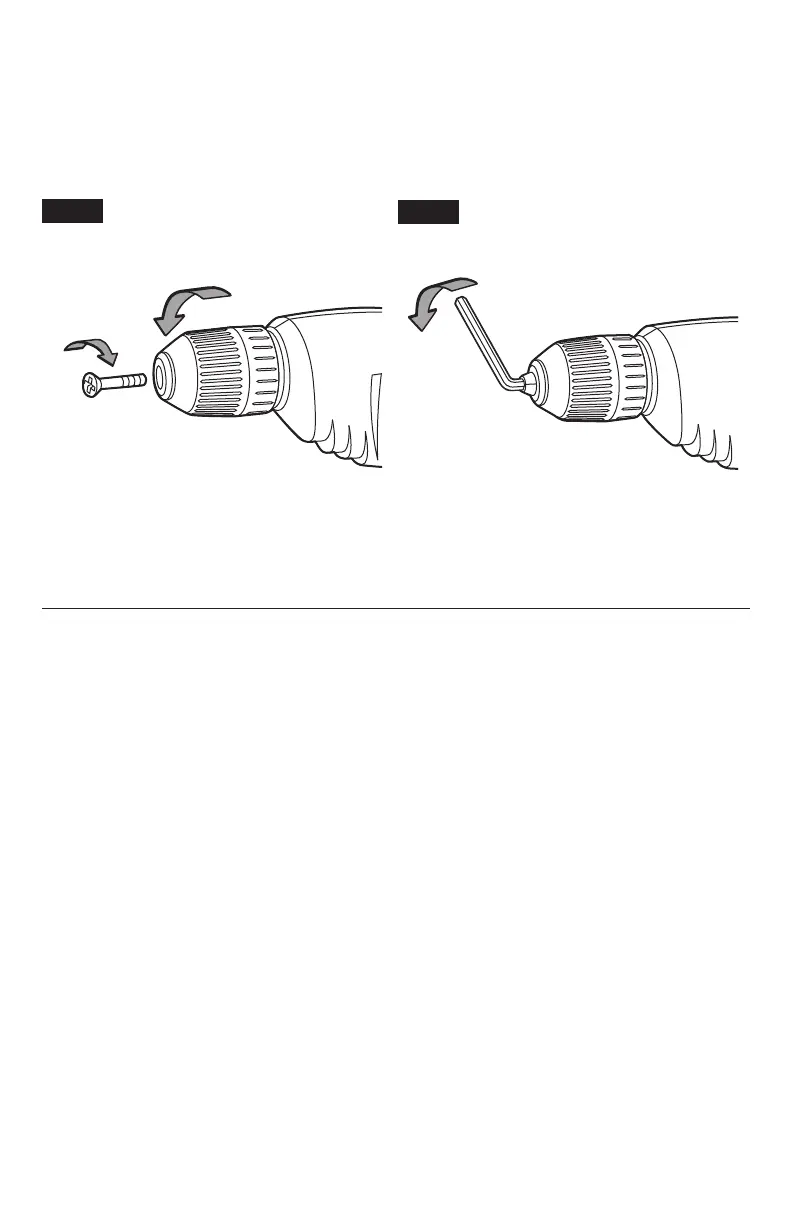

Removing Chuck

Open the chuck all the way, remove left-hand thread screw inside chuck by turning it clockwise

(Fig. 3).

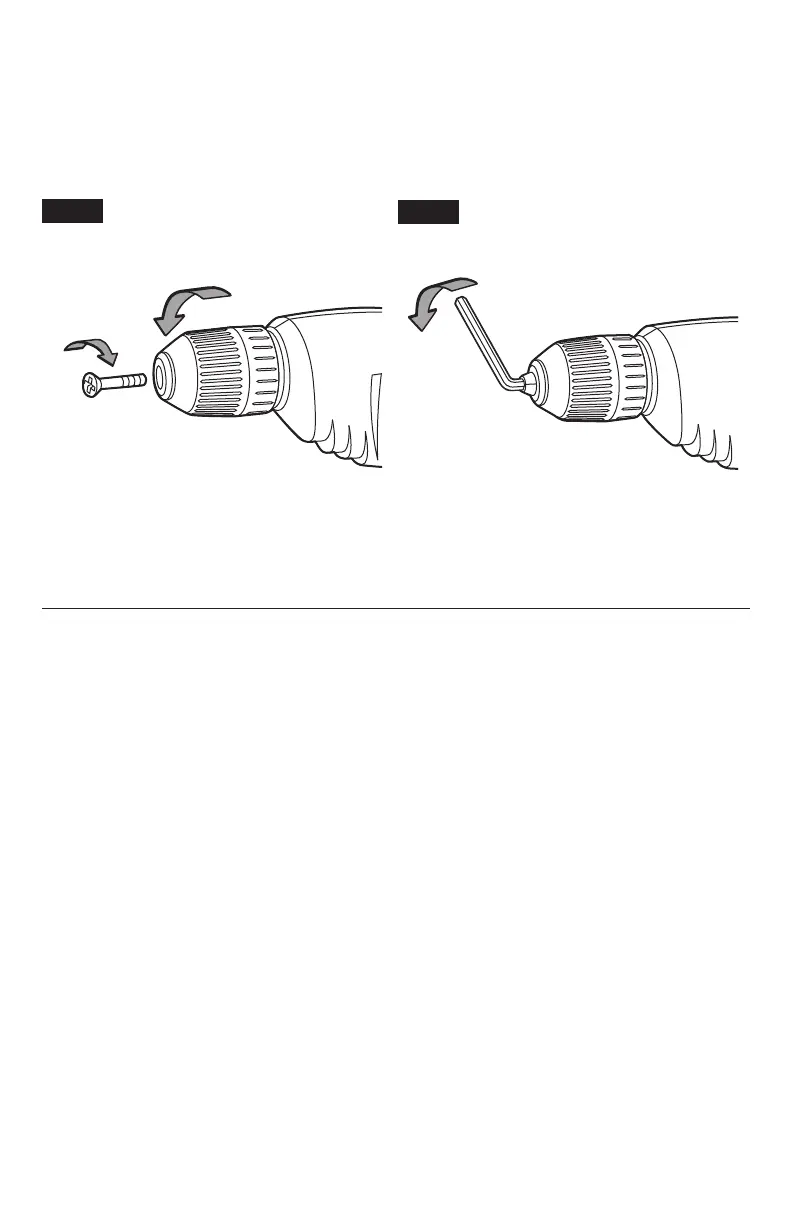

Insert the short arm of a 3/8” hex key wrench and close jaws on ats of wrench (Fig. 4). Strike

long arm of wrench sharply counter¬clockwise, remove wrench and unthread chuck from

spindle.

Fig. 3

Counter

Clockwise

Clockwise

Fig. 4

Counter

Clockwise

Installing Chuck

Always keep the spindle threads, the threads of the chuck and securing screw free of debris.

To install a chuck, reverse “removing the chuck” procedure.

Operating Tips

You will extend the life of your bits and do neater work if you always put the bit in contact with

the work before pulling the trigger. During the operation, hold the tool rmly and exert light,

steady pressure. Too much pressure at low speed will stall the tool. Too little pressure will

keep the bit from cutting and cause excess friction by sliding over the surface. This can be

damaging to both tool and bit.

Drill Bits

Always inspect drill bits for excessive wear. Use only bits that are sharp and in good condition.

TWIST BITS: Available with straight and reduced shanks for wood and light duty metal drilling.

High speed bits cut faster and last longer on hard materials.

CARBIDE TIPPED BITS: Used for drilling stone, concrete, plaster, cement and other unusually

hard nonmetals. Use continuous heavy feed pressure when employing carbide tip bits.

Loading...

Loading...