16

5. Set the motor housing upside down on the motor-housing top cap with the collet pointing up

and remove the bit.

WARNING

Always remove the cutter bit from collet/nut when the router is not being

used. Leaving bits installed could result in accidents causing serious

personal injury.

Adjusting the Depth of Cut

WARNING

Your router should never be turned on or be connected to the power

source when you are assembling parts, making adjustments, installing or

removing collets/nuts, cutter bits, cleaning the product, or when it is not in use. Disconnecting

the router will prevent accidental starting, which could cause serious personal injury.

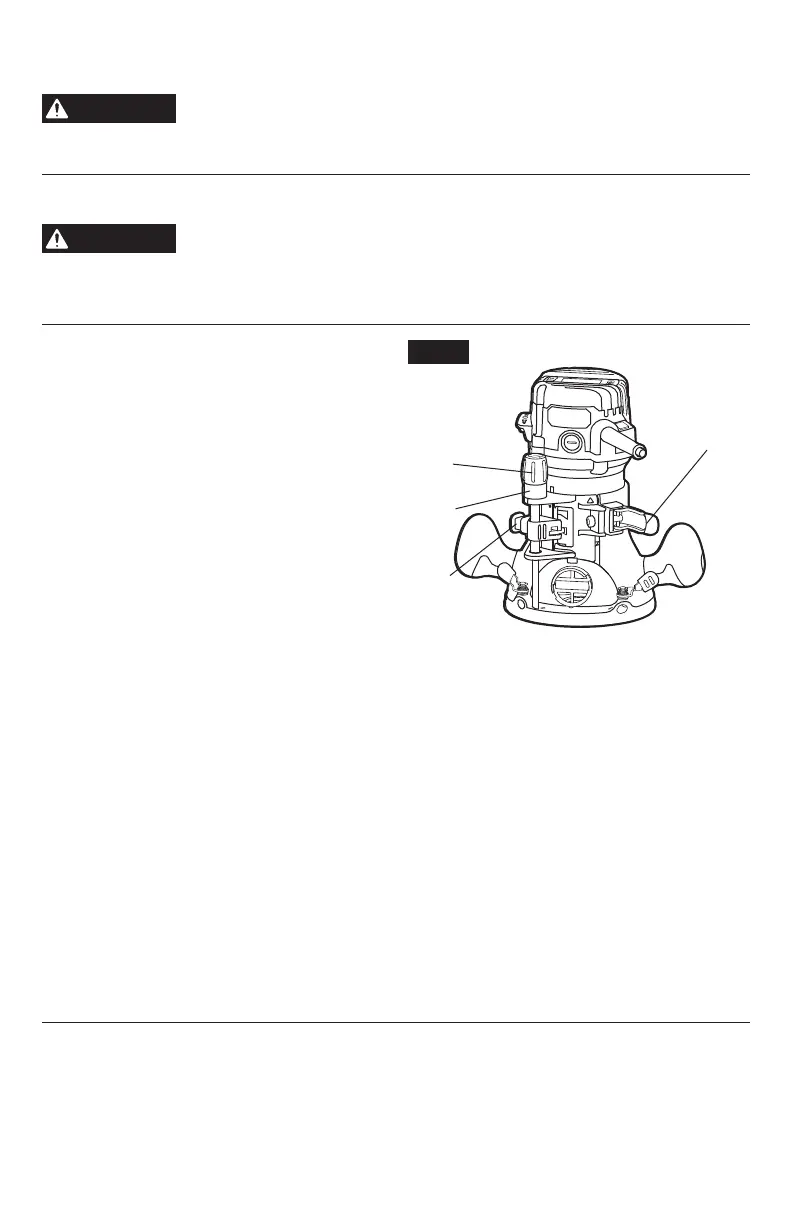

Depth Adjustment With Fixed

Base (FIG. 6)

Notice:

All depth adjustments on the xed

base must be made with the motor clamp

open.

Notice:

For all xed base routers, the cutter bit

depth equals the amount of the cutter that is

exposed below the surface of the sub-base.

The xed base is designed with a micrometer-

ne adjustment system. When the bit is

lowered to the approximate position desired

(coarse setting), the system then can be micro-

adjusted to the precise depth required.

Coarse Adjustment

Depressing the coarse-adjustment knob (B) allows you to quickly lower or raise the cutter bit

to an approximate depth setting.

Fine Adjustments

NOTICE:

Be sure that the micrometer-ne adjustment system is engaged before making ne

adjustments. Test it by turning the ne-adjustment dial (C) clockwise and counter-clockwise to

see if the bit lowers and raises.

The depth-indicator ring (D) located on the ne-adjustment dial is marked in 1/256- inch

increments. Turning the ne-adjustment dial counterclockwise 180° (1/2 turn), lowers the

cutter bit 1/32 inch. One full turn counterclockwise 360° (zero “0” to zero “0”) lowers the bit

1/16 inch.

NOTICE:

The depth-indictor ring (D) may be reset to zero “0” without moving the ne-

adjustment dial. This allows the user to begin adjustments from any reference point desired.

NOTICE:

Making a single, deep cut is never advisable. Smaller diameter cutter bits are easily

broken by too much side thrust and torque. Larger cutter bits will cause a rough cut and be

difcult to guide and control. For these reasons, do not exceed 1/8-in. depth of cut in a single

pass.

Fig. 6

D

B

A

C

Loading...

Loading...