18

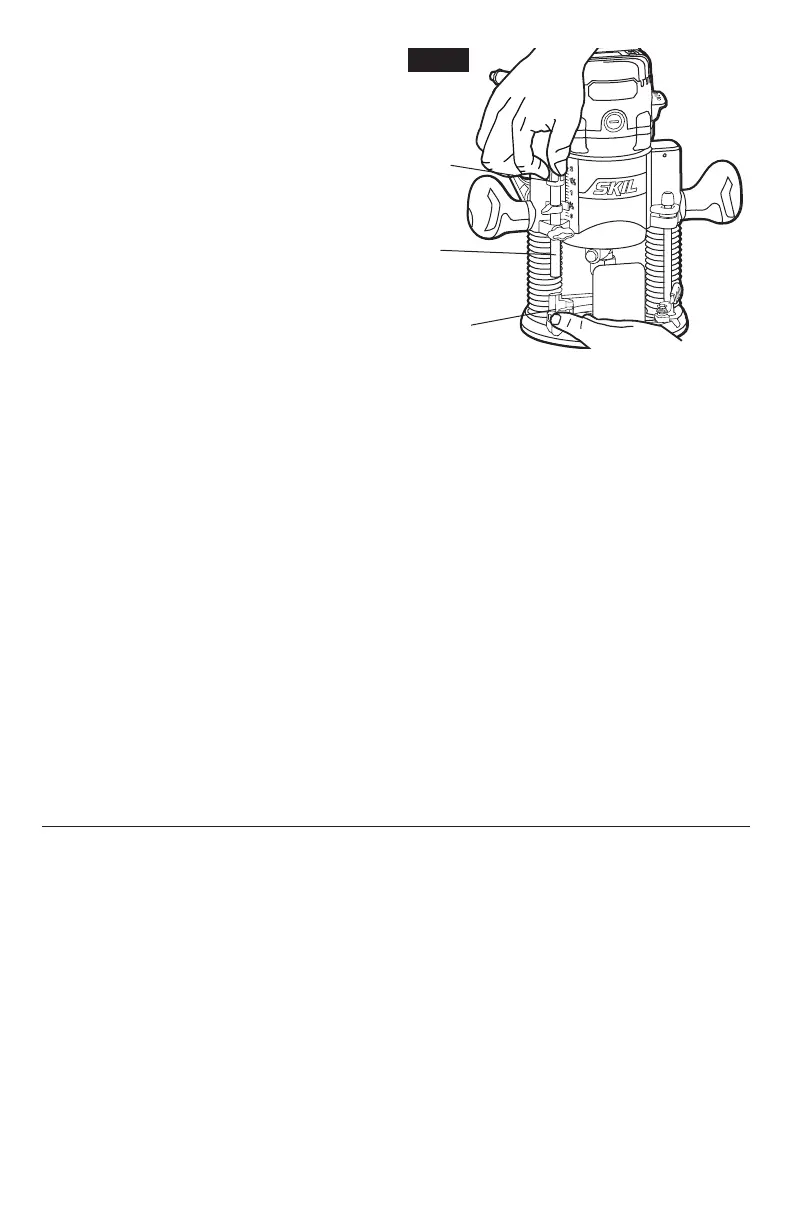

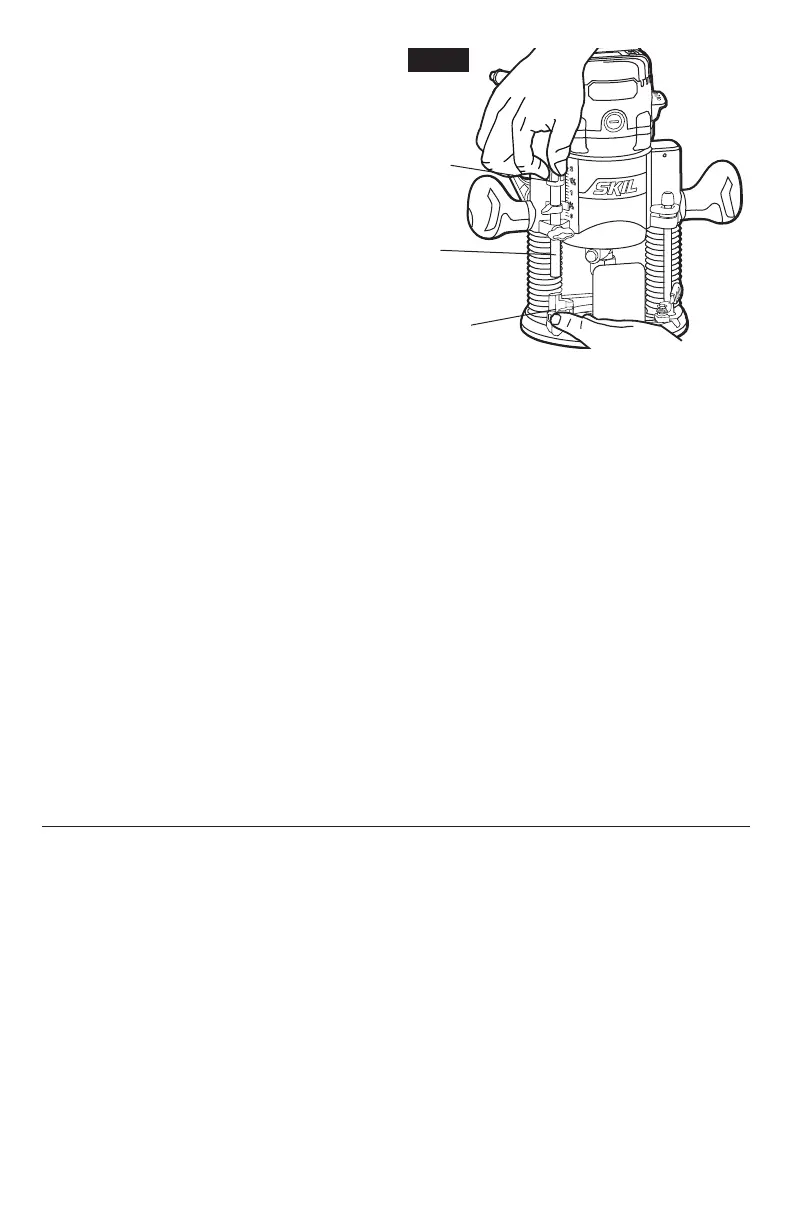

Using the Depth-Stop Turret to Set Up Deep

Cuts (Fig. 9)

NOTICE:

Making a single, deep cut is never

advisable. Smaller diameter cutter bits are

easily broken by too much side thrust and

torque. Larger cutter bits will cause a rough cut

and be difcult to guide and control. For these

reasons, do not exceed 1/8-in. depth of cut in a

single pass.

To produce deep cuts, always make several

progressively deeper cuts by starting with the

highest step on the depth-stop turret, and, after

each cut, rotate the turret to the next lower step

until the lowest step is reached.

Each of the steps progresses by 1/4 inch

increments. The 4 steps represent a total of “0”

inch to 3/4-inch with a full 360º rotation of the turret. Repeat this process if necessary.

Micro-adjustments with the Depth Rod and Depth-Stop Turret (Fig. 9)

The depth rod has a ne-adjustment knob (A) that turns a screw (B) (inside the rod) either

clockwise or counterclockwise to lower or raise the depth rod on the turret (C) for micro-ne

adjustments of the plunge depth.

Each complete revolution of the ne adjustment knob adjusts the plunging depth by

approximately 1/32 inch.

A reference indicator line is embossed into the depth rod under the ne-adjustment knob to

set a reference point of “0”.

When micro-adjusting the plunge depth, always make sure that the ne-adjustment knob has

been turned down (clockwise) several revolutions from the top before setting the depth rod

and depth-stop turret.

Always set your micro-adjustments with the plunge action locked in the raised, (or up) position.

To use the ne-adjustment knob after the depth rod and turret have been set, check the nal

depth setting and micro-adjust as follows:

•

To micro-increase the plunge depth, raise the fine-adjustment knob by turning the knob

counterclockwise the desired amount.

•

To micro-reduce the plunge depth, lower the fine-adjustment knob by turning the knob

clockwise the desired amount.

Fig. 9

C

B

A

Loading...

Loading...