Page 3

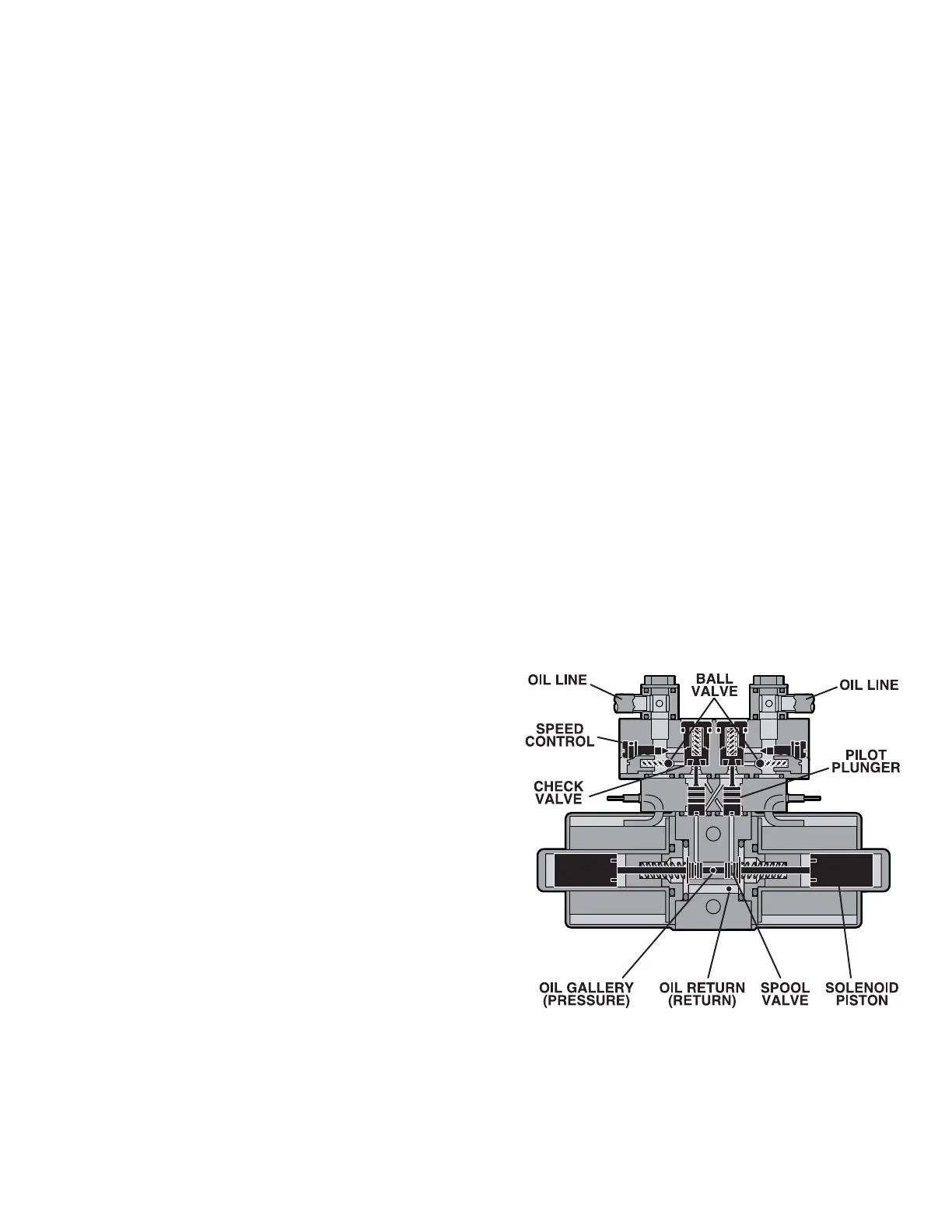

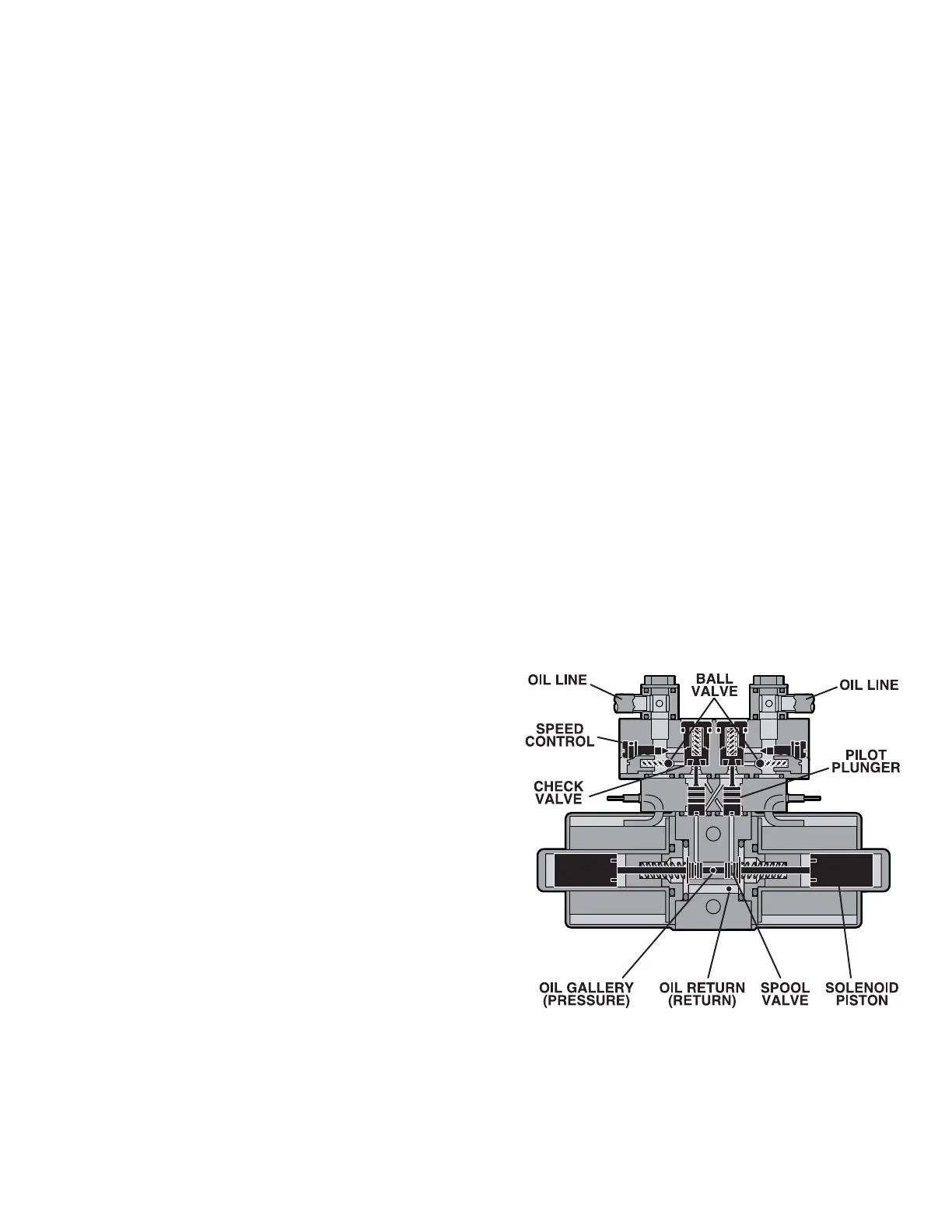

Figure 1-5. Mini-Valve in Neutral Position

c. Mini-Valves

The operation of the mini-valves is identical for all

table functions except the elevation and brake

circuits. These two hydraulic circuits use a 3-way

(single check valve) type mini-valve. All other func-

tions use a 4-way (dual check valve) type mini-

valve.

Either type mini-valve is controlled by two pushing

type, electrically operated solenoids. The sole-

noids push the spool valve (located in the lower

portion of the valve) one way or the other. This

motion opens the main supply galley (which has

pump pressure) allowing the oil to flow through the

various parts of the mini-valve to the function. The

spool valve also opens an oil return circuit which

allows the oil to return to the oil reservoir.

The main components of the mini-valve and their

functions are listed below:

1. Spool Valve - Opens the main oil galley

(pump pressure) to either mini-valve outlet de-

pending on which direction the spool valve is

pushed. Also it provides a return path for the oil

returning back into the reservoir.

2. Pilot Plunger - There are two plungers in a

four-way mini-valve (one in a 3-way mini-valve),

one under each check valve. The purpose of the

pilot plungers is to mechanically open the return

check valve allowing the oil to return back into the

reservoir.

3. Check Valve - Two are provided in each

four-way mini-valve to seal the oil in the cylinders

and oil lines and prevent any movement of the

table. One check valve is provided in a 3-way mini-

valve.

4. Speed Adjustments - There are two speed

adjustments in each mini-valve. They are needle

valve type controls which restrict the volume of oil

returning back into the reservoir, thereby control-

ling the speed of the table surface movement. A 3-

way mini-valve has only one speed adjustment.

The speed controls are always located in the return

oil circuit. This prevents uncontrolled movement of

the piston in the slave cylinder due to one side of

the piston being loaded with hydraulic pressure

and the other side having no load.

Also, by using this control method, it doesn’t matter

what size cylinder and piston is used because the

speed can be controlled by restricting the return oil.

If the pump puts out more volume to a certain slave

cylinder than the speed control is allowing to go

back to the reservoir, the pressure relief valve

provides an alternate path for the pump oil.

d. Mini-Valve in Neutral Position

(No fluid flow) See figure 1-5.

1. Spool Valve Centered - This closes off both

oil pressure and oil return galleys.

2. Pilot Plungers Both Closed -The pilot plung-

ers control the opening of the check valves. If they

are closed, the check valves must be closed.

3. Check Valves - Both check valves are

closed trapping the oil in the cylinder and oil lines.

4. Speed Adjustment - When the mini-valve is

in the neutral position, the speed adjustment does

not affect anything because there is not any oil

flow.

Loading...

Loading...