Page 10

MK SINK OWNERS MANUAL• REV4

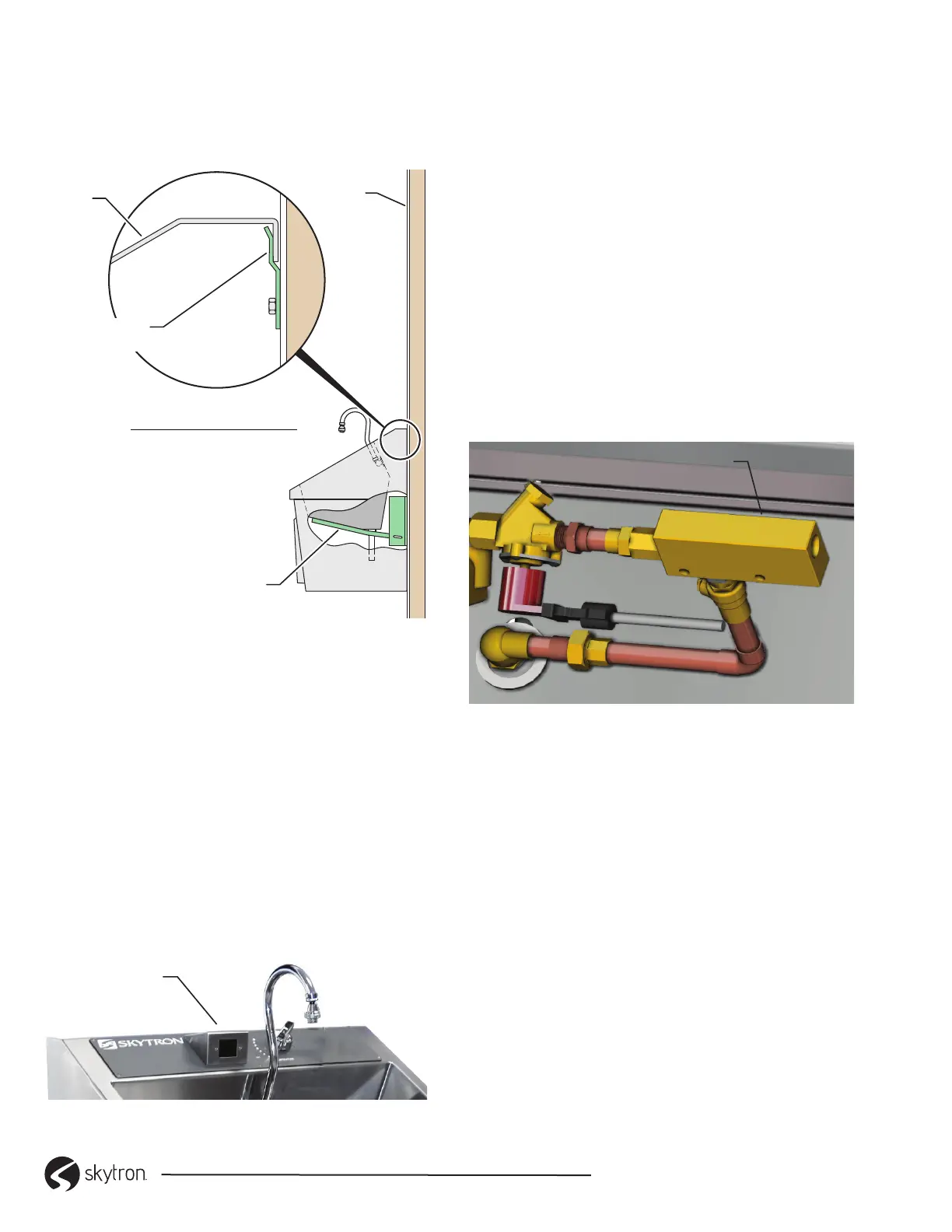

3-3. Attach Sink to Support Brackets

1. Install sink assembly on brackets making sure

the sink assembly is captured by the wall “Z”

bracket(s) (Figure 2).

WALL “Z”

BRACKET

FINISHED

WALL

TYPICAL SINK

ATTACHMENT SECTION

MAIN SUPPORT

BRACKET

SINK

Figure 2. Sink Attachment.

3-4. Infrared Controls Installation

Infrared Self-Activated Sinks are supplied with a 24V

power transformer(s) that connects to a standard

duplex outlet (110/120V outlet required).

Single basin sinks have one sensor, dual basin sinks

have two sensors (one for each basin) and triple

basin sinks have three sensors (one for each basin).

1. Plug the transformer(s) into the outlet.

2. A red LED will ash in the sensor window

(Figure 3). DO NOT interrupt the sensor beam

until the light turns o.

3.

INFRARED

SENSOR

Figure 3. Infrared Sensor

3-4-1. Sensor Initialization

The sensors are pre-set and equipped with a logic

board. The sensors determines the range during

initialization period (The time after initial power until

the light turns o is approximately 5 minutes). The

range is approximately 12-14” in front of the sensor

and is 25 degrees at peak.

During the initialization period, the sensors allow for

xed objects that may be within the sensors’ range.

The sensors are equipped with a two second on/o

delay, and no-time-out feature. This prevents the sink

from turning on when walking past at a normal pace

and no-time out allows for an uninterrupted scrub.

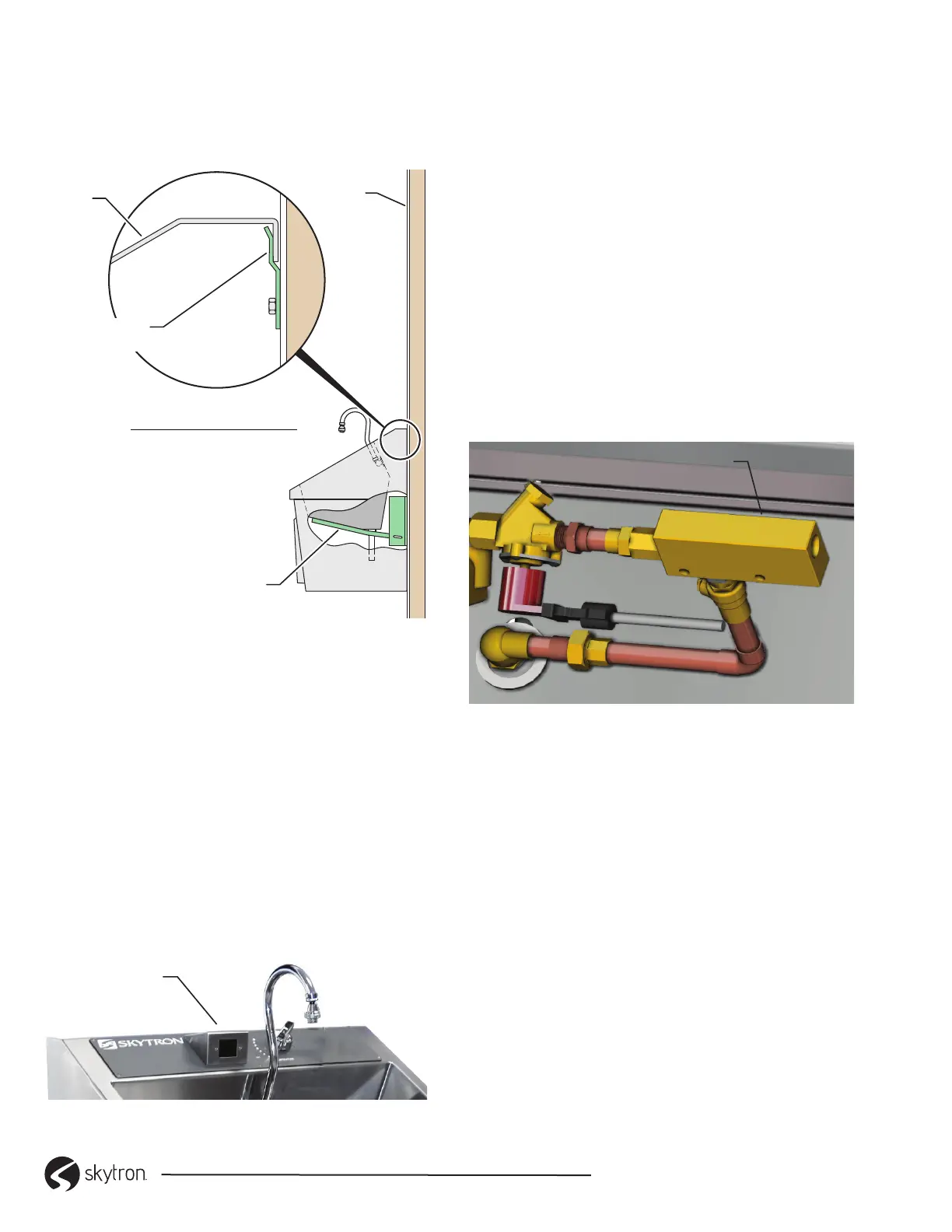

3-5. In-line Flow Switch Timer Controller

The in-line ow switch timer controller is available

only on Infrared Activated Scrub Sinks (Figure 4).

IN-LINE FLOW TIMER CONTROLLER

Figure 4. In-line Flow Switch Timer Controller

This is an explosion-proof brass ow switch, actuation

set point 0.50 GPM (1.89 LPM), and calibrated for

water at standard conditions. It is used for accurate

detection of excessive or insucient ow rates.

Loading...

Loading...