Health and safety at work act 1974 – designed to protect people and the environment from work

place activities. It places certain duties and responsibilities on employers, employees, self- e m p l o y e d people,

designers and manufactures.

• Employer’s responsibilities - must ensure workplaces under their control are safe and free from

hazards. Ensure the safety of employees, self-employed, visitors, trespassers and the general public who could be

affected by the work. Everything they provide for use, tools, plant and equipment must be fit for purpose, safe to use and

the personnel trained to use it

• Employee’s responsibilities- must take care of them selves and others who may be affected by their

acts or omissions. Co-operate with their employer. Do not tamper with or interfere with or misuse anything provided for

safety

• Failure to comply with legislation- could result in loss of you job and all the financial implications that

can bring but it could also result in prosecution. The severity of the breach of legislation and any accidents or incidents

related would dictate what type of court proceedings you could face. If you have fulfilled your legal requirements and can

provide proof of this in court then you would likely be found Not Guilty but If you were found guilty you could face a prison

sentence or a substantial fine

To fully understand the above Act specific training and guidance is required

Method Statement- detailed description of how to carry out a job safely and efficiently. All involved in the work

must be briefed on its contents. Workers must follow the Method statement unless they fell it is not suitable then they

should stop and report it and have the method statement amended. Competent people must only amend Method

Statement

Risk Assessment- is a legal requirement before work starts. It is a detailed assessment of the risk involved in

doing and job and provides information on how to reduce the risk level down to an acceptable level.

Hazards- this is anything, which can cause harm to people plant or equipment.

• Excavations or Trenches – risk of collapse. The minimum distance to keep away from open

excavations is at least the depth of the trench i.e. if its 2m deep you stay 2 m back

• Working at height- any place you can fall from and be injured is considered working at height. The top of a

mound, climbing into or out of a machine. Standing by the edge of a n excavation

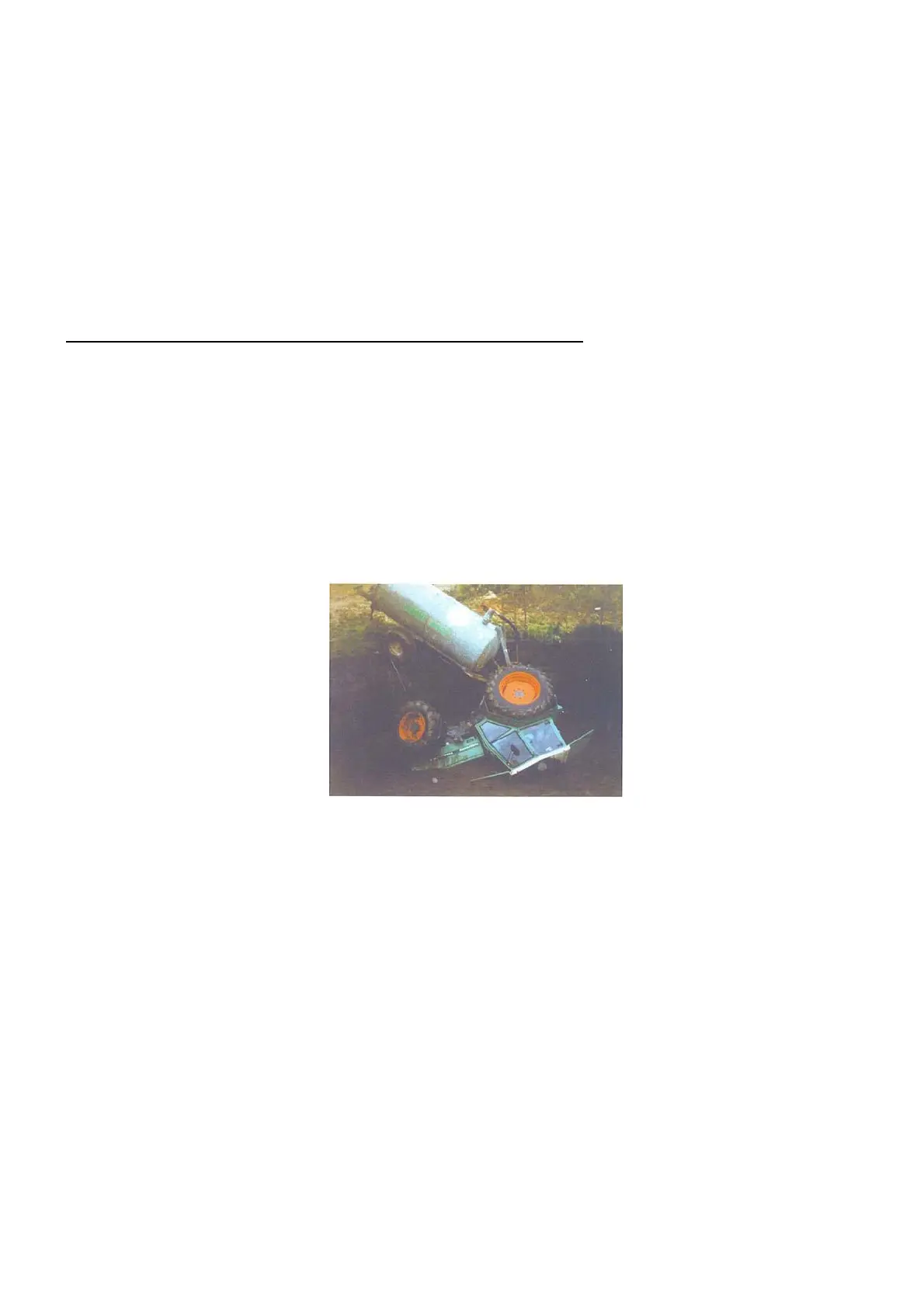

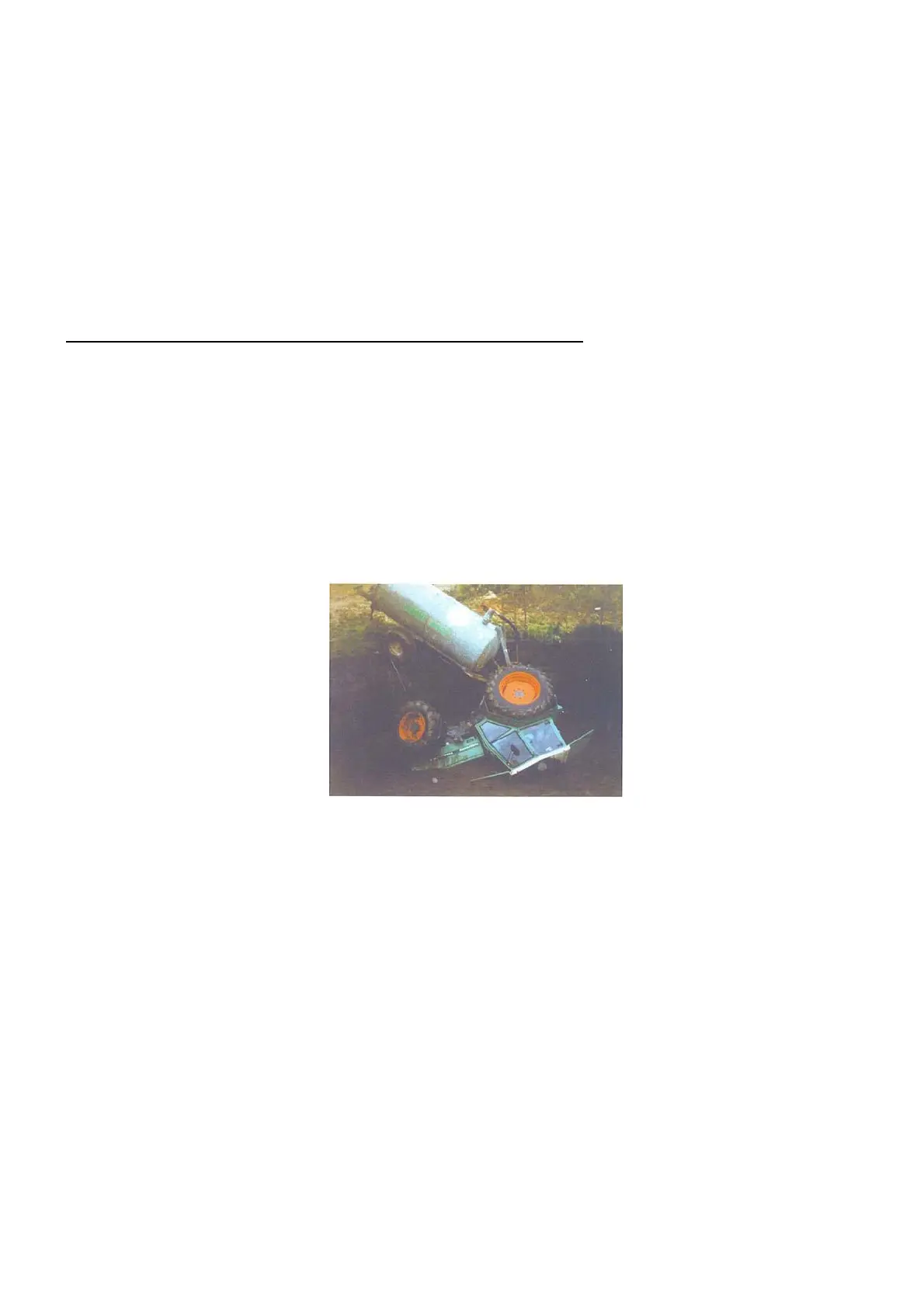

• Slopes- where ever possible the weight always faces up hill i.e. empty dumper skips face downhill and loaded

skips face uphill. Extreme care should be taken if working across a slope. Avoid turning on slopes if possible

• Overhead cables- the minimum distance to be maintained form over head cables mounted on wooden

poles is 9m from the greatest reach of the machine and 15m from cables on metal pylons. Electricity can arc or

jump a gap.

• Confined spaces- anywhere there is restriction on operating area can be considered a confined

space. There is a greater risk of accident or damage. The Minimum distance, which should be maintained

between a fixed, obstacle and the machine is 600mm (this is deemed to be the smallest distance a person can

go through without being injured). If this distance can’t be maintained then the area should be fenced off and

signs erected. Fumes, dust, noise, lack of visibility and insufficient room to maneuver are all hazards associated

with confined areas

• Plant operations – are regarded as “safety Critical operations” because of the potential risk of an

accident. Plant Operators can cause harm to themselves or other people if they carry out an unsafe act.

• Pedestrian areas- care should be taken when operating in pedestrian areas. A safe route for

pedestrians should be provided with suitable signage and lighting. Enough room for material storage and vehicle

movements is required. Noise, dust and fume levels should be reduced where possible. Required permits,

method statements and risk assessments should be in place.

2

SLL PLANT AND QUARRY TRAINING SERVICES LIMITED

Loading...

Loading...