Caution Caution

Circulating Fluid

14. If tap water is used, it should satisfy the qual-

ity standards shown below.

Circulating Fluid

8. The thermo-con must not be operated with-

out circulating fluid.

The pump can break due to idling.

9. If the tank lid is opened after the supply of cir-

culating fluid, the circulating fluid may spill

out depending on the condition of external

piping.

10. If an external tank is used, the circulating flu-

id may spill out from the internal tank lid de-

pending on where the external tank is in-

stalled.

Confirm that the internal tank has no leakage if using an exter-

nal tank.

11. If there is a point where fluid is released to at-

mosphere externally (tank or piping), mini-

mize the piping resistance at the circulating

fluid return side.

If the piping resistance is too large, the piping may be crushed,

or the built-in circulator tank may be deformed or cracked be-

cause the pressure in the piping for return will become nega-

tive. The built-in circulator tank is made of resin (PE). Therefore,

the tank may be crushed if the pressure is negative. Special at-

tention must be paid if the flow rate of the circulating fluid is

high. To avoid a negative pressure of –0.02 MPa or below, the

piping return should be as thick and short as possible to mini-

mize piping resistance. It is also effective to restrict the flow rate

of circulating fluid or remove the gasket of internal tank for the

release to atmosphere.

12. Fluorinated fluid is outside of the specifica-

tions.

If it is used in the thermo-con, static electricity will be generated

by the flow of fluid. This static electricity may be discharged to

the board of the thermo-con, causing damage or operation fail-

ure and loss of data of such as set temperature.

Also, as the specific gravity of the fluorinated fluid is 1.5 to 1.8

times of water, the pump will be overloaded, which also causes

fluorinated fluid to be outside the specifications. Therefore, if

fluorinated fluid is used, please contact SMC and we will intro-

duce a suitable special product (water-cooled type).

13. Avoid operation with cavitation or bubbles

due to low fluid level in the tank. This may

shorten the pump life.

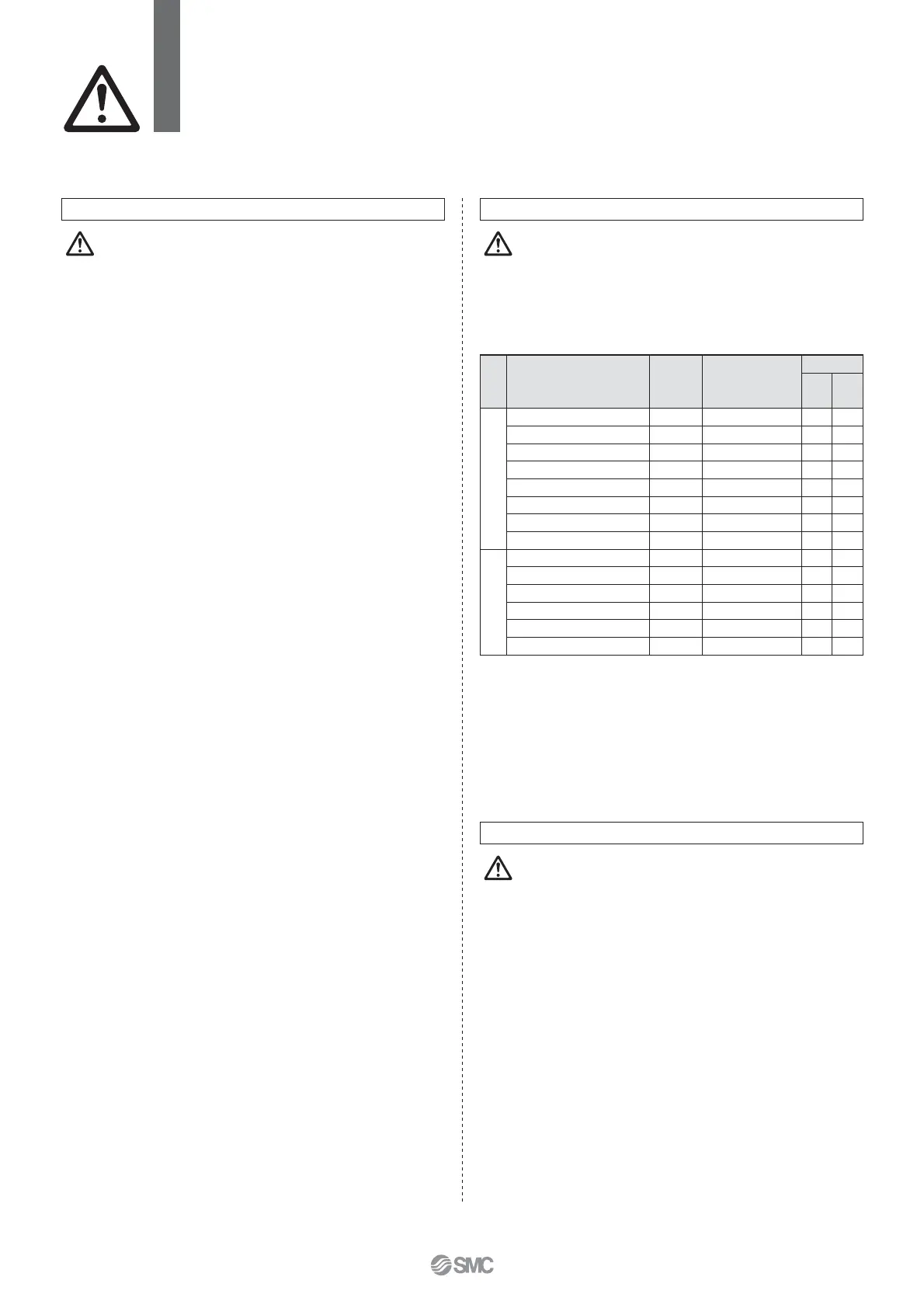

Tap Water (as Circulating Fluid) Quality Standards

The Japan Refrigeration and Air Conditioning Industry Association

JRA GL-02-1994 “Cooling water system – Circulating type – Make-up water”

Warning

Maintenance

15.

The tank capacity is approximately 1 litre at the High

level, and approximately 0.4 litres at the Low level.

When the fluid level goes below the Low level,

“ERR20” (Low fl uid level alarm) will be generated.

1. Prevention of electric shock and fire

Do not operate the switch with wet hands. Also, do not operate

the thermo-con with water left on it.

2. Action in the case of error

If any error such as abnormal sounds, smoke, or bad smell oc-

curs, cut off the power at once, and stop supplying and convey-

ing fluid. Please contact SMC or a sales distributor to repair the

thermo-con.

3. Regular inspection

Check the following items at least once a month. The inspec-

tion must be done by an operator who has sufficient knowledge

and experience.

a) Check of displayed contents.

b) Check of temperature, vibration and abnormal sounds in the

body of the thermo-con.

c) Check of the voltage and current of the power supply system.

d) Check for leakage and contamination of the circulating fluid

and intrusion of foreign objects to it, and subsequent re-

placement of fluid.

e) Check for flow condition and temperature of radiation air.

∗ In the case of [MΩ폷 cm], it will be 0.003 to 0.01.

폷

: Factors that have an effect on corrosion or scale generation.

폷 Even if the water quality standards are met, complete prevention of corrosion

is not guaranteed.

Item Unit Standard value

Influence

Corrosion

Scale

generation

Standard item

pH (at 25 °C) — 6.0 to 8.0

Electrical conductivity (25 °C)

[µS/cm] 100

∗

to 300

∗

Chloride ion (Cl

–

) [mg/L] 50 or less

Sulfuric acid ion (SO

4

2–

) [mg/L] 50 or less

Acid consumption amount (at pH4.8)

[mg/L] 50 or less

Total hardness [mg/L] 70 or less

Calcium hardness

(CaCO

3

)

[mg/L] 50 or less

Ionic state silica (SiO

2

) [mg/L] 30 or less

Reference item

Iron (Fe) [mg/L] 0.3 or less

Copper (Cu) [mg/L] 0.1 or less

Sulfide ion (S

2

–

) [mg/L]

Should not be detected.

Ammonium ion (NH

4

+

) [mg/L] 0.1 or less

Residual chlorine (Cl) [mg/L] 0.3 or less

Free carbon (CO

2

) [mg/L] 4.0 or less

Series HECR

Specific Product Precautions 2

Be sure to read this before handling. Refer to the back cover for Safety Instructions. For

Temperature Control Equipment Precautions, refer to “Handling Precautions for SMC

Products” and the Operation Manual on the SMC website, http://www.smc.eu

22

Loading...

Loading...