Instructions for the installer

20

9.2 Adjustment for LPG

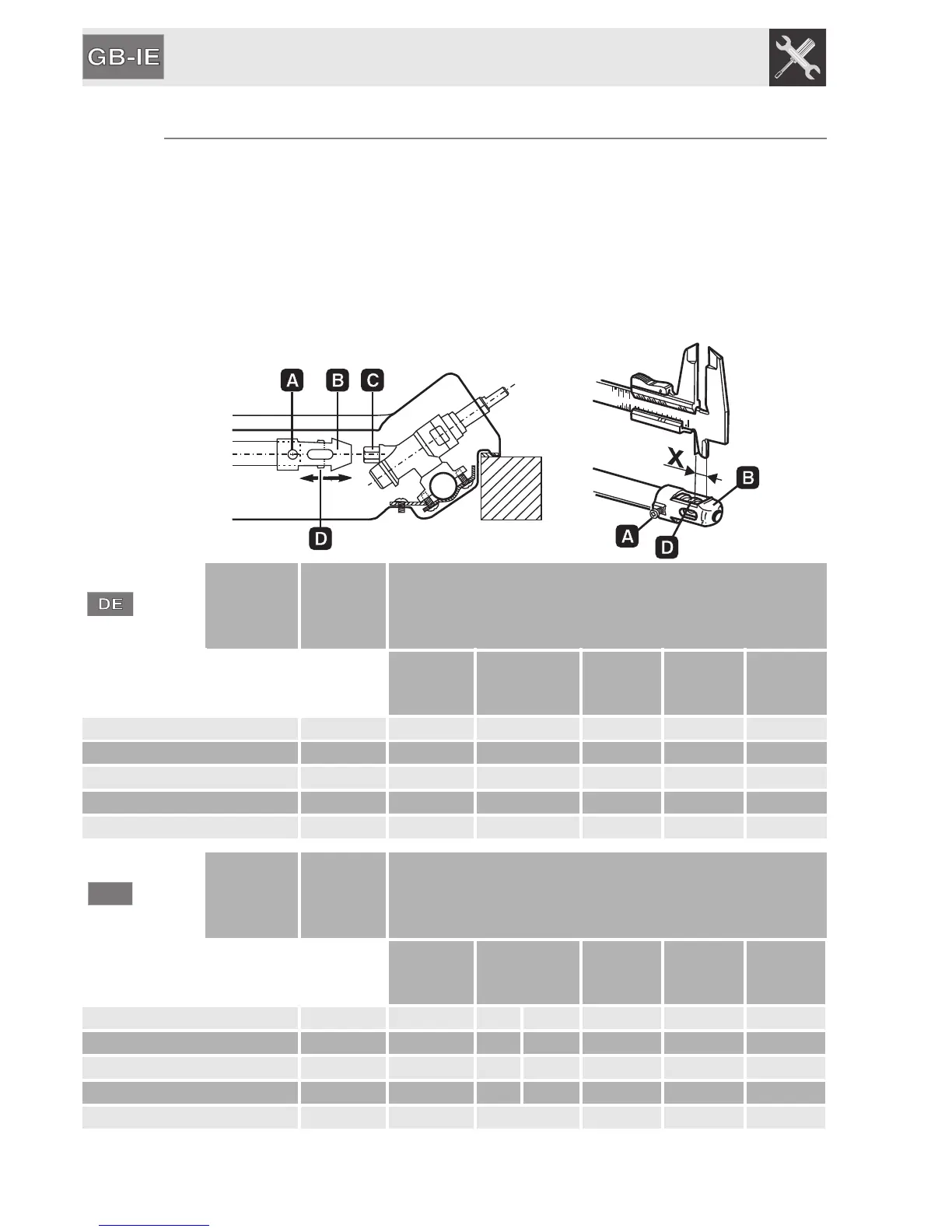

Loosen screw A and push support B all the way. Using a a double head, remove

nozzle C and replace it with the appropriate nozzle, following the instructions in the

tables for the type of gas to be used. The nozzle tightening torque must be no more

than 3 Nm. Reposition support B so that nozzle C is covered perfectly.

Move the Venturi tube D to adjust the air flow until distance “X” is reached indicated

in the chart in paragraph "5.5 Primary air adjustment” and then secure the tube by

means of screw A. After the adjustments have been carried out, restore the seals

with sealing wax or equivalent material.

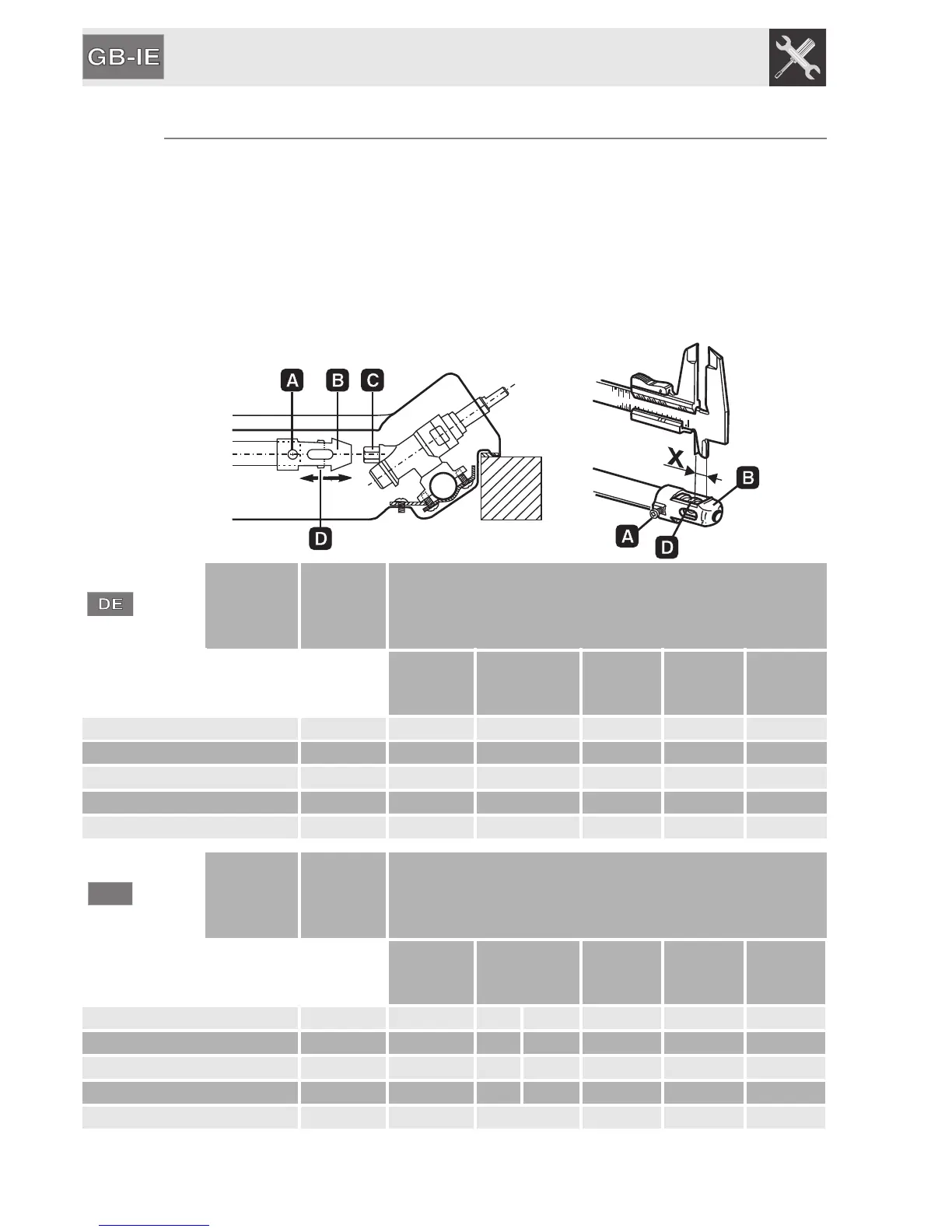

Burner

Rated

heating

capacity

(kW)

LPG – G30/G31 50 mbar

Nozzle

diameter

1/100 mm

Bypass

mm

1/100

Reduced

capacity

(W)

Capacity

g/h G30

Capacity

g/h G31

Auxiliary (1) 1.05 42 26 380 76 75

Semi-rapid (2) 1.65 54 26 380 120 118

Rapid (3) 2.55 67 33 650 185 182

Rapid (4) 3.1 73 37 750 225 222

Ultra-rapid (5) 3.9 82 55 1600 283 279

Burner

Rated

heating

capacity

(kW)

LPG – G30/G31 28/37 mbar

Nozzle

diameter

1/100 mm

Bypass

mm

1/100

Reduced

capacity

(W)

Capacity

g/h G30

Capacity

g/h G31

Auxiliary (1) 1.05 48 30 33 (*) 380 76 75

Semi-rapid (2) 1.65 62 30 33 (*) 380 120 118

Rapid (3) 2.55 76 37 40 (*) 650 185 182

Rapid (4) 3.1 85 43 45 (*) 750 225 222

Ultra-rapid (5) 3.9 95 65 1600 283 279

(*) By-pass value for appliances without valves.

Loading...

Loading...