IN STAL LAT IO N

US E

MA INT EN AN CE

12

TURN OFF THE APPLIANCE AND ALLOW TO COOL BEFORE CLEANING.

COLD WATER OR A DAMP CLOTH MAY DAMAGE HOT SURFACES.

CLEANING

TEST PRESSURE POINT

THE OPERATIONS MUST BE CARRIED OUT BY AUTHORIZED PERSONNEL.

SMEV DECLINES ANY RESPONSIBILITY RELATED TO SAID INTERVENTION.

The test pressure point is located on the pressure regulator.

WARRANTY

In case of warranty claim or any repair or replacement which becomes necessary, the vehicle or part dealer who sold

the product should be contacted. Give model and serial number on all repair part orders and correspondence.

DO NOT USE ABRASIVE, CORROSIVE, CHLORIDE-BASED PRODUCTS OR STEEL OR

OTHER SCOURING PADS. DO NOT LEAVE ACIDIC SUBSTANCES E.G. VINEGAR, SALT,

LEMON JUICE ETC. ON THE APPLIANCE SURFACES. STAINLESS STEEL SURFACES

AND ENAMELED PARTS SHOULD ONLY BE WASHED WITH SOAPY WATER OR

NEUTRAL DETERGENT, RINSED AND DRIED. ONLY USE CLEAN SPONGES OR

CLOTHS.

INJECTOR

CLEANING AND/OR REPLACEMENT OF BURNER INJECTORS (FIG. 1 - PAG. 25)

When removing or installing an injector, the holder must be held with a suitable tool.

THE OPERATIONS MUST BE CARRIED OUT BY AUTHORIZED PERSONNEL.

SMEV DECLINES ANY RESPONSIBILITY RELATED TO SAID INTERVENTION.

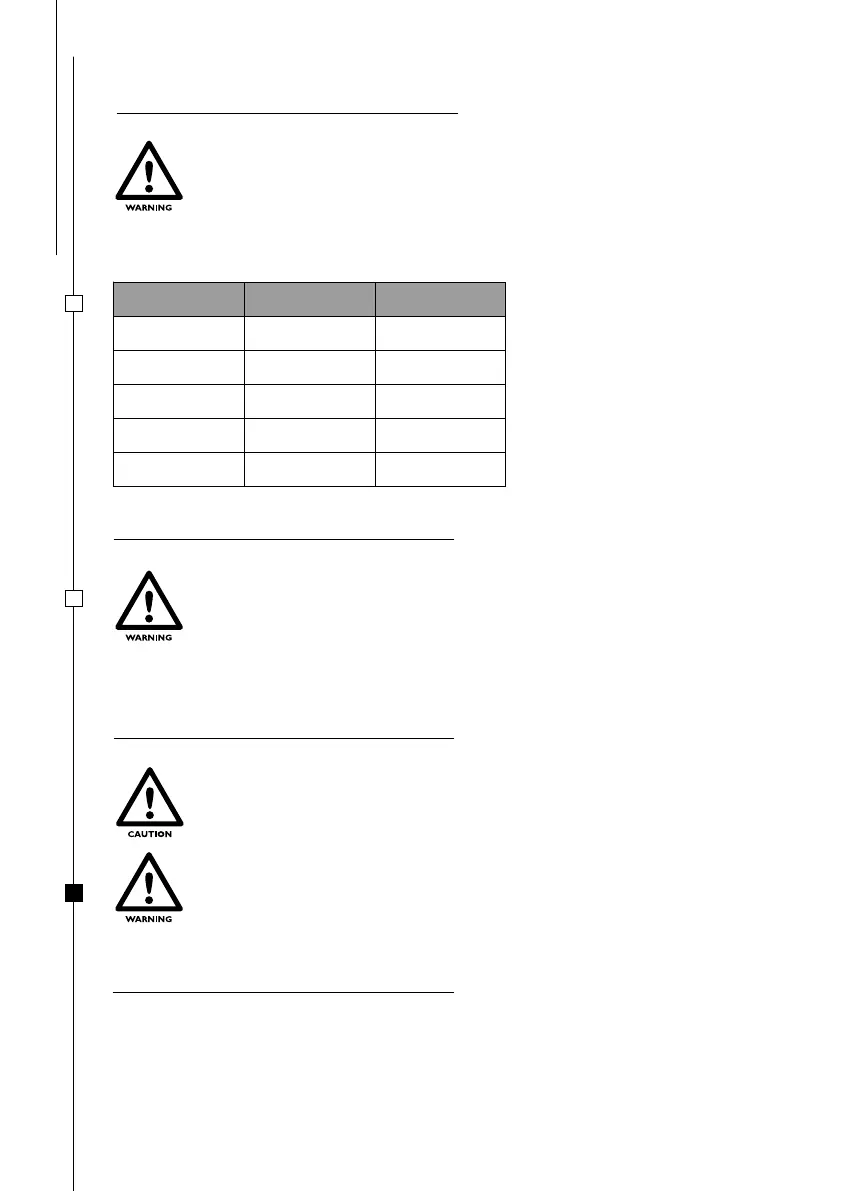

BURNERS

INJECTOR

Ø mm

HOB NUMBER

AUXILIARY

Ø 47 mm - 1 27/32”

0,57 57

SEMIRAPID

Ø 62 mm - 2 7/16”

0,72 72

RAPID

Ø 77 mm - 3”

0,80 80

BROILER 0,67 67

OVEN 0,57 57

Loading...

Loading...