INSTALLATION AND OPERATING INSTRUCTIONS

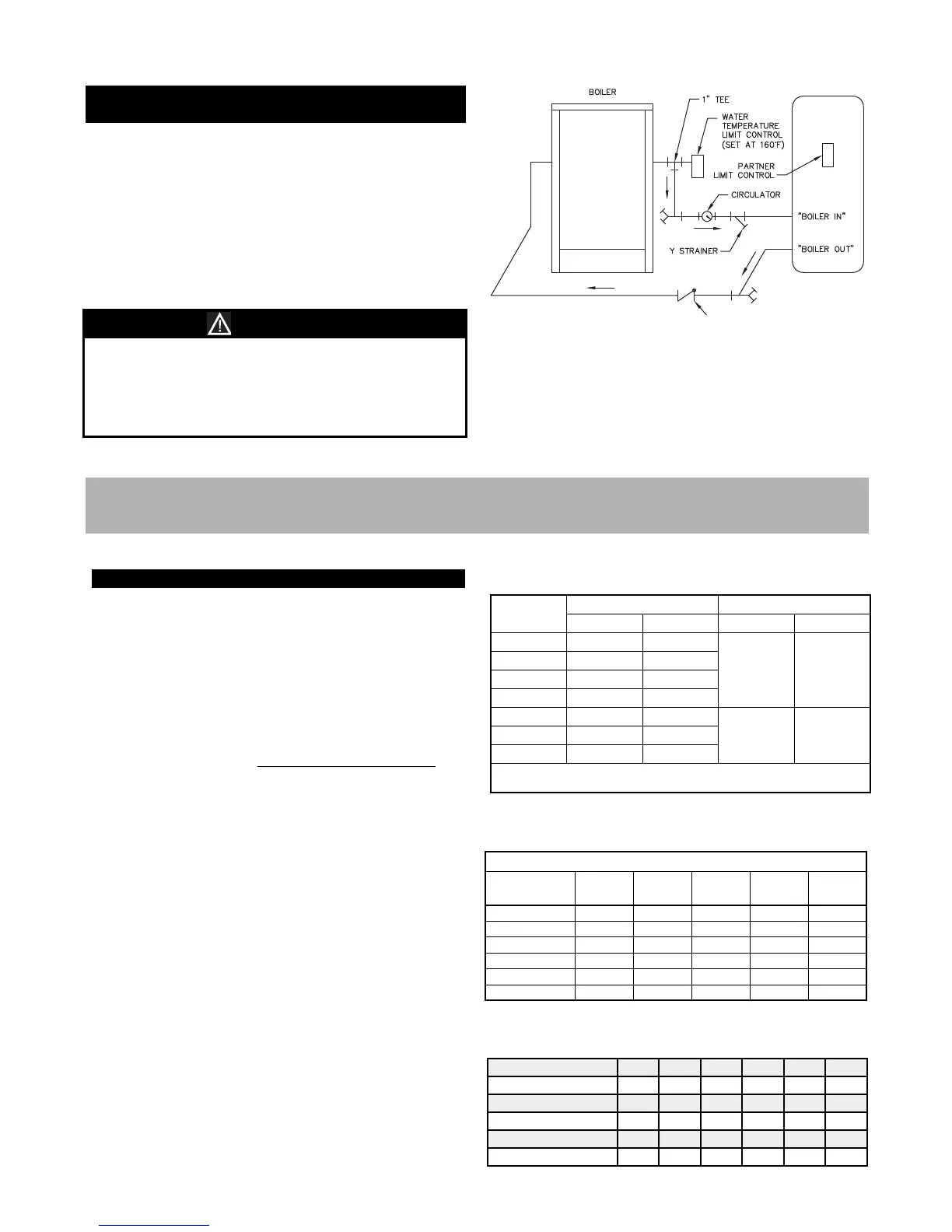

B. STEAM BOILER INDIRECT WATER

HEATER PIPING

1. See Figure 4.2 for typical installation.

2. Install Boiler Water Temperature Limit Control in 1"

Tee on supply connection (same side of boiler as low

water cut-off). Set Limit at 160°F to avoid steam

generation during periods when only the domestic

water is calling for heat.

3. Install circulator and strainer in supply piping. Install

check valve to prevent gravity circulation.

Maintain water level near normal water line to avoid

steam generation during periods when only the

domestic water is calling for heat.

Tank performance reduced when supplied by steam

boiler.

NOTICE

Figure 4.2: Typical Steam Boiler Indirect

Water Heater Piping

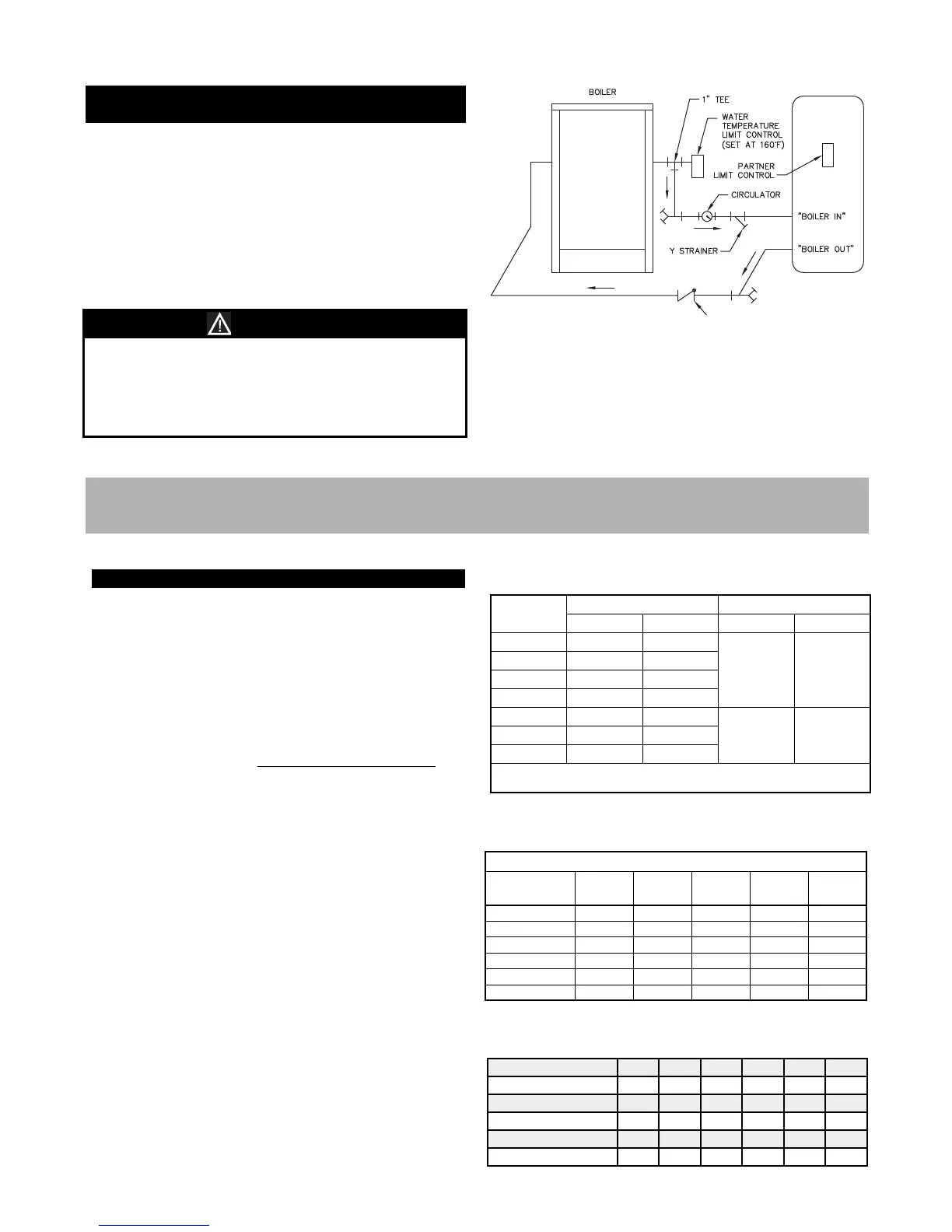

A. INSTALLATION

1. Pipe gas to the boiler in accordance with local codes.

In the absence of local regulations refer to the

National Fuel Gas Code, ANSI Z223.1/NFPA 54.

2. Size and install the gas supply piping to provide a

supply of gas sufficient to meet the maximum demand

of all appliances without excessive pressure drop.

3. The rate of gas to be provided to the boiler can be

determined by:

Obtain the gas heating value of the gas from the gas

supplier. As an alternative use Table 5.1.

4. Table 5.2 shows the maximum flow capacity of

several pipe sizes based on 0.3 inches of water

pressure drop. These values are based on a specific

gravity of 0.60. Apply the factors indicated in Table

5.3 for gas with specific gravity other than 0.60 to

obtain corrected capacities.

5. FUEL PIPING

Based on Specific Gravity of 0.60

Pipe Length

(Feet)

1/2"

Pipe

3/4"

Pipe

1"

Pipe

1-1/4"

Pipe

1-1/2"

Pipe

10 132 278 520 1,050 1,600

20 92 190 350 730 1,100

30 73 152 285 590 890

40 63 130 245 500 760

50 56 115 215 440 670

60 50 105 195 400 610

Table 5.2: Maximum Capacity of Pipe in CFH for a

Pressure Drop of 0.3" of Water

Table 5.3: Maximum Capacity Correction Factors

Specific Gravity other than 0.60

Table 5.1: Gas Input & Valve Inlet

Specific Gravity 0.50 0.55 0.60 0.65 0.70 0.75

Correction Factor 1.10 1.04 1.00 0.96 0.93 0.90

Specific Gravity 0.80 0.85 0.90 1.00 1.10 1.20

Correction Factor 0.87 0.84 0.82 0.78 0.74 0.71

Specific Gravity 1.30 1.40 1.50 1.60 1.70 1.80

Correction Factor 0.68 0.66 0.63 0.61 0.59 0.58

Boiler Input (BTU/HR)

CFH =

Gas Heating Value (BTU/FT³)

Model

Gas Input

1

(CFH) Gas Valve Inlet

2

(NPT)

Nat. Gas LP Gas Nat. Gat LP Gas

88 88.5 35.4

1/2" 1/2"

118 118.0 47.2

147 147.5 59.0

177 177.0 70.8

206 206.5 82.6

3/4" 3/4"

236 236.0 94.4

288 287.5 115.0

1. Natural Gas Based on 1000 Btu./Cubic Foot, LP Gas Based on 2500 Btu./Cubic Foot.

2. See instructions for sizing gas supply piping.

10

Loading...

Loading...