B. OPERATION

1. Assure that the gas supply pressure to the boiler is

regulated to 1/2 psi or less (approx. 13.5 inches of

water).

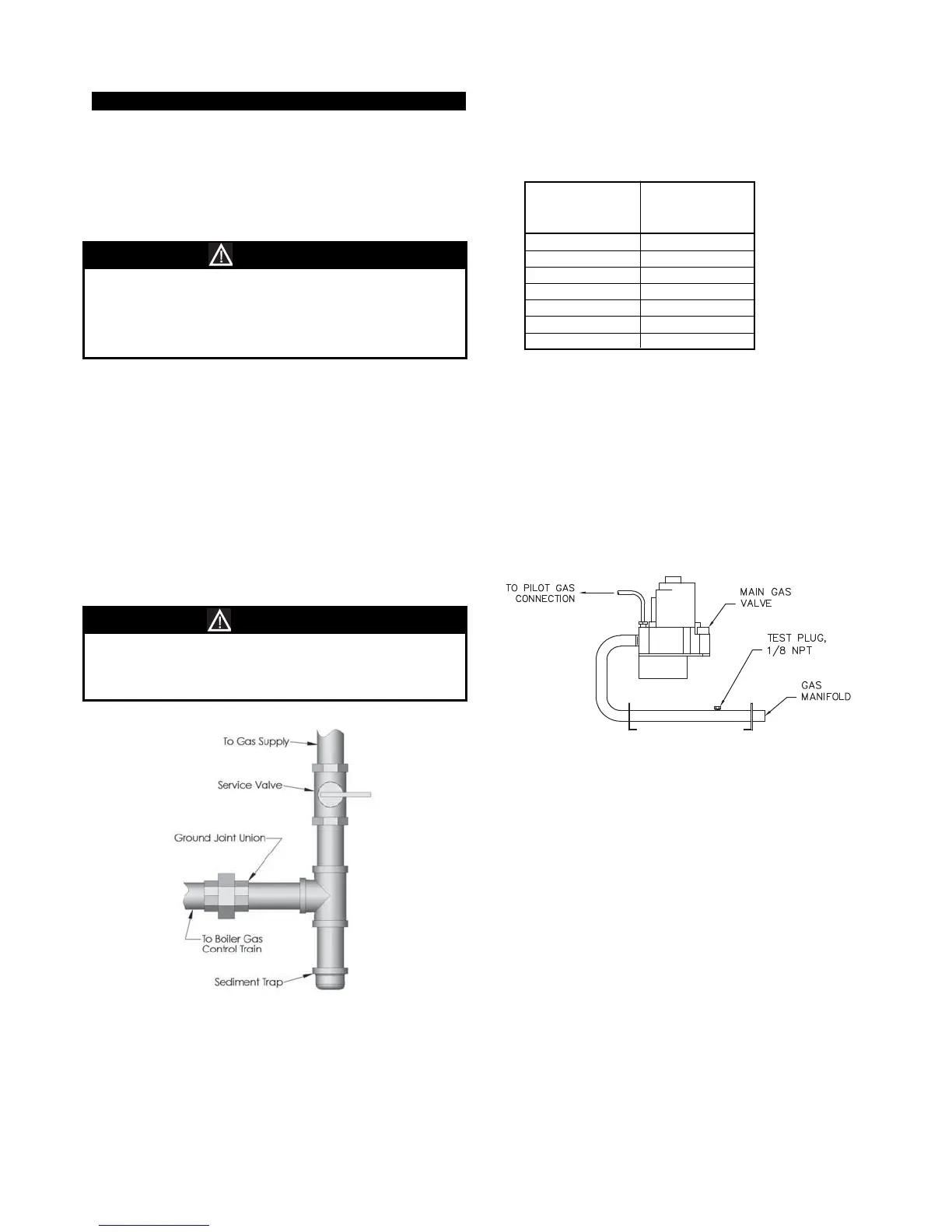

2. Install a service valve, sediment trap, and ground

joint union at the gas supply connection as shown in

Figure 5.1.

3. Check piping for leaks. Use an approved gas

detector or a non-corrosive leak detection fluid. If

leaks are found, turn off all gas supply to the

appliance and repair as necessary.

4. The boiler and its individual shut off valve must be

disconnected from the gas supply piping system

during any pressure testing of that system at test

pressures in excess of 1/2 psi (3.5kPa).

The boiler must be isolated from the gas supply

piping system by closing its individual manual shut

off valve during any pressure testing of the gas

supply piping system at test pressures equal to or less

than 1/2 psi (3.5 kPa).

5. Refer to table 5.4 for minimum supply pressure for

the purpose of input adjustment.

6. Install the boiler such that the gas ignition system

components are protected from water (dripping,

spraying, rain, etc.) during appliance operation and

service (circulator replacement, condensate trap

clean out, control replacement, etc.)

7. The boiler and its gas connection must be leak tested

before placing the boiler in operation.

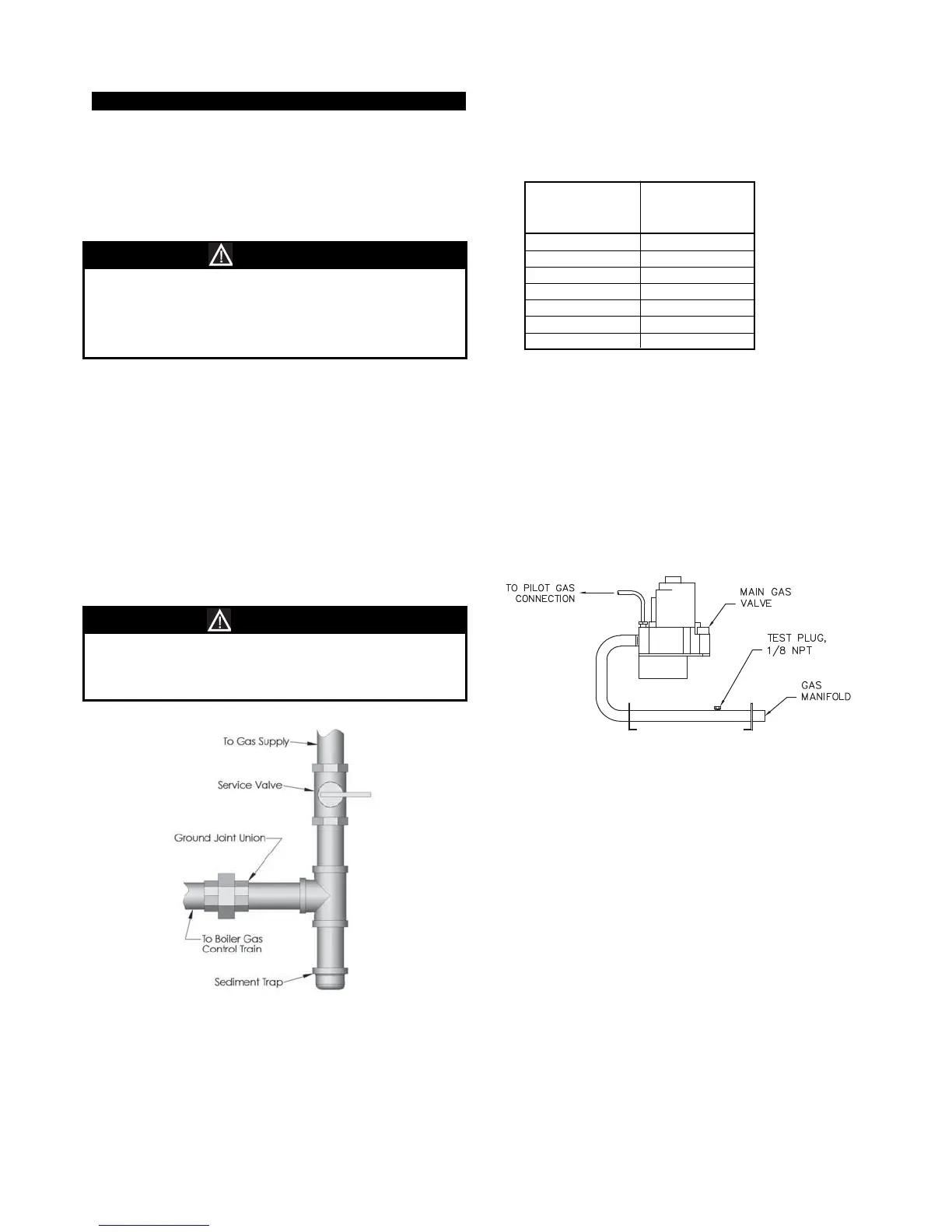

8. Typical gas train manifold is illustrated in Figure 5.2.

11

INSTALLATION AND OPERATING INSTRUCTIONS

Do not subject the boiler gas valve to pressure in

excess of 1/2 psi (3.5 kPa). Doing so may damage the

valve.

CAUTION

Use a pipe joint sealing compound that is resistant to

the action of liquefied petroleum gas. A non-resistant

compound may lose sealing ability in the presence of

this gas, resulting in a gas leak and fire or explosion

potential.

CAUTION

Figure 5.1

Model

Supply

Pressure

(in. Water)

88 5.00

118 5.00

147 5.00

177 5.35

206 5.00

236 5.00

288 5.56

Table 5.4: Minimum Supply

Pressure Natural Gas

Figure 5.2: Gas Train Manifold

Loading...

Loading...