Section 4 - ADJUSTMENTS & REPAIR

WARNING

DO NOT attempt any adjustments, maintenance, service

or repairs with the engine running. Stop engine. Stop

blade. Engage parking brake. Remove key. Remove

spark plug wire from spark plug and secure away from

plug. Engine and components are HOT. Avoid serious

burns, allow all parts to cool before working on machine.

Fuel Filler Cap and Vent must be closed securely to

prevent fuel spillage. Once blade is disengaged, it should

come to a complete stop in 3 seconds or less. If the

blade continues to rotate after 3 seconds, the blade

brake must be adjusted. Refer to Section “BLADE

BRAKE ADJUSTMENT” for adjustment procedures or

return machine to an authorized SNAPPER dealer for

adjustment. DO NOT CONTINUE to operate machine

until blade brake is adjusted and functioning properly.

4.2.2. BLADE BRAKE ADJUSTMENT

1. Remove Belt Cover. Refer to Section “BLADE

BELT COVER REMOVAL”.

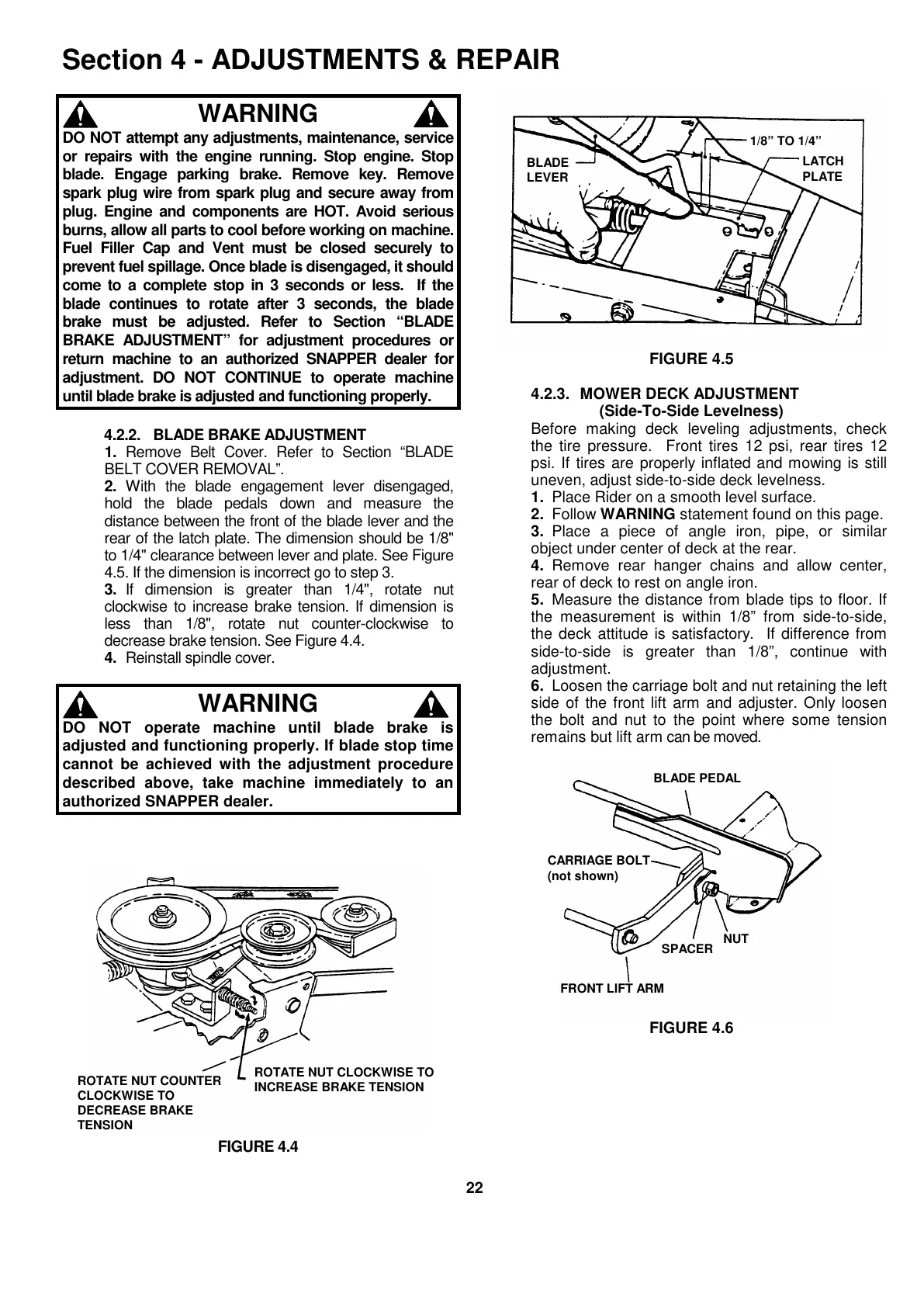

2. With the blade engagement lever disengaged,

hold the blade pedals down and measure the

distance between the front of the blade lever and the

rear of the latch plate. The dimension should be 1/8"

to 1/4" clearance between lever and plate. See Figure

4.5. If the dimension is incorrect go to step 3.

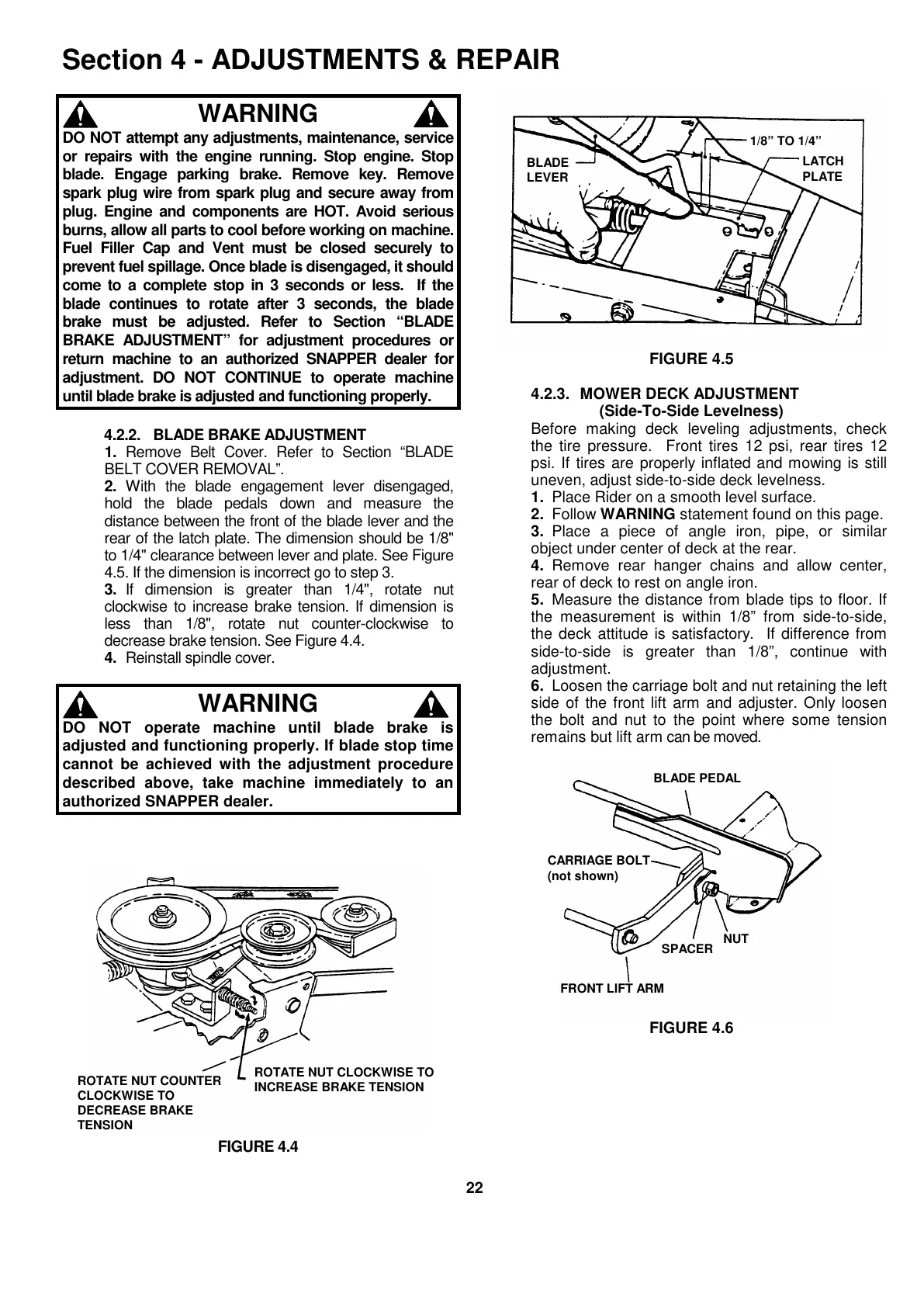

3. If dimension is greater than 1/4", rotate nut

clockwise to increase brake tension. If dimension is

less than 1/8", rotate nut counter-clockwise to

decrease brake tension. See Figure 4.4.

4. Reinstall spindle cover.

WARNING

DO NOT operate machine until blade brake is

adjusted and functioning properly. If blade stop time

cannot be achieved with the adjustment procedure

described above, take machine immediately to an

authorized SNAPPER dealer.

FIGURE 4.4

FIGURE 4.5

4.2.3. MOWER DECK ADJUSTMENT

(Side-To-Side Levelness)

Before making deck leveling adjustments, check

the tire pressure. Front tires 12 psi, rear tires 12

psi. If tires are properly inflated and mowing is still

uneven, adjust side-to-side deck levelness.

1. Place Rider on a smooth level surface.

2. Follow WARNING statement found on this page.

3. Place a piece of angle iron, pipe, or similar

object under center of deck at the rear.

4. Remove rear hanger chains and allow center,

rear of deck to rest on angle iron.

5. Measure the distance from blade tips to floor. If

the measurement is within 1/8” from side-to-side,

the deck attitude is satisfactory. If difference from

side-to-side is greater than 1/8”, continue with

adjustment.

6. Loosen the carriage bolt and nut retaining the left

side of the front lift arm and adjuster. Only loosen

the bolt and nut to the point where some tension

remains but lift arm can be moved.

FIGURE 4.6

ROTATE NUT CLOCKWISE TO

INCREASE BRAKE TENSION

ROTATE NUT COUNTER

CLOCKWISE TO

DECREASE BRAKE

TENSION

BLADE

LEVER

1/8” TO 1/4”

LATCH

PLATE

BLADE PEDAL

Loading...

Loading...