Fluid Level Switch

Instructions

• Locate desired level switch mounting position. Suggested

placement is 1/5 of max reservoir height.

• Carefully drill side of reservoir using 13/16” bit. A step bit is

recommended for best drilling results. Hole

must be free of nicks or shavings for proper

sealing.

• Remove rubber seal from level switch.

Insert seal into reservoir until fully seated.

Goop can be used around the edges of the

hole.

• Lubricate exterior of level switch with water

and insert into seal until fully seated. Position level switch so GT

symbol is at six o’clock position.

• Wait 30 minutes for Goop to cure, then test for leaks. With fluid

level above level switch, float should be angled up. With fluid

level below level switch, float should be in horizontal position.

• Connect one black wire from level switch to ground.

• Connect other black wire from level switch to white wire from

LED.

• Connect red wire from LED to +12 volt key on power source.

Low Fluid LED

Black

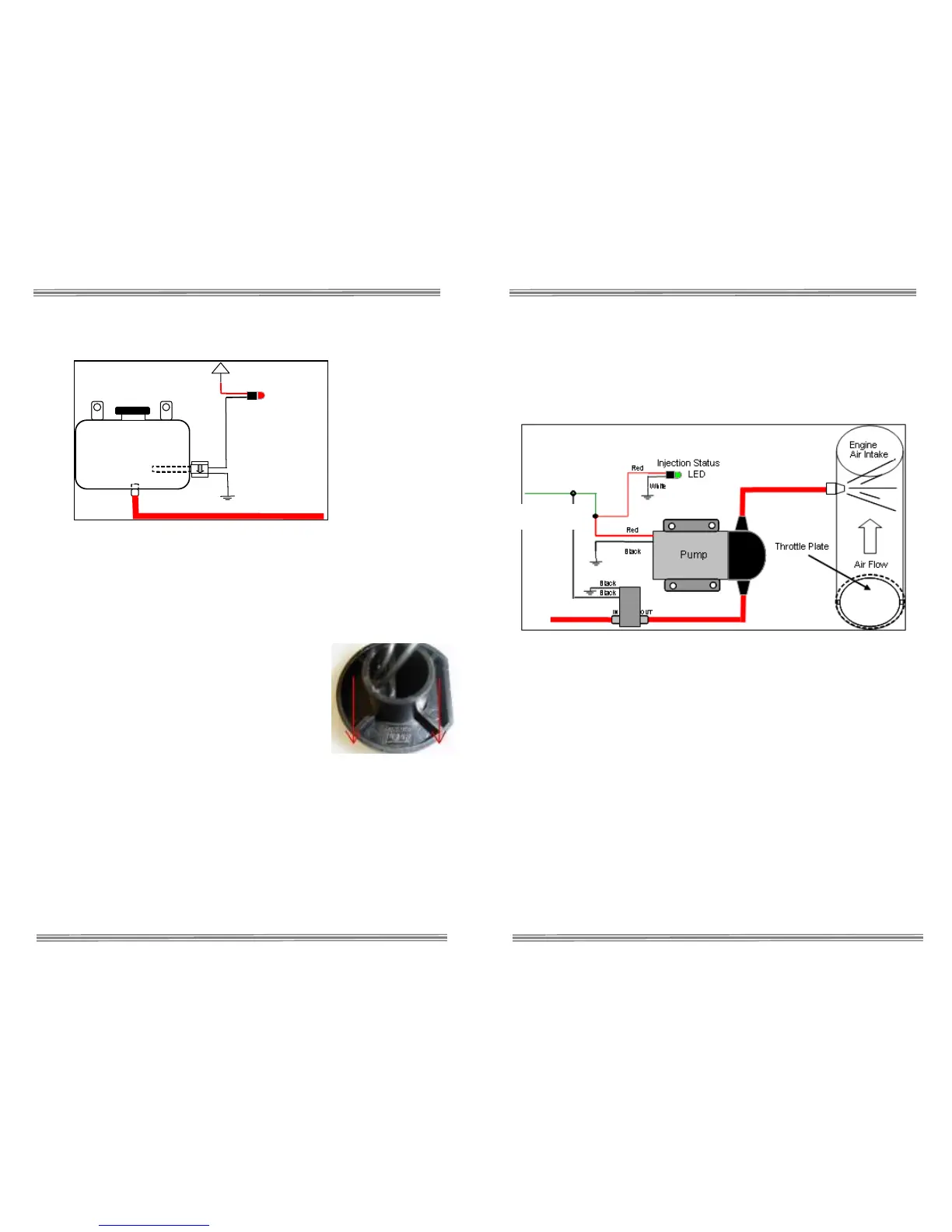

Solenoid Upgrade (optional)

The optional Solenoid Upgrade (#40060) is required if the nozzle is to be

installed after the intake throttle plate (as shown), or the fluid reservoir is

mounted higher then the nozzle. It is highly recommended for trunk-

mount reservoirs.

Finger thread the two 1/8” NPT quick connect fittings into ports labeled (2

or IN) and (1 or OUT) on the solenoid. Tighten an additional half turn

past finger tight.

Note: Solenoid must be installed Pre-pump to ensure

correct operation.

Cut high pressure line at location solenoid is to be installed. Insert ends

of cut line into quick connect fittings of solenoid. The port labeled (2 or

IN) is the inlet and the port labeled (1 or OUT) is the outlet. Gently pull

on line to check secure connection. If line pulls out, re-insert farther into

fitting to engage locking clips. If high pressure line removal is required,

firmly press in metal fitting ring to disengage locking clips while pulling

hose from fitting.

Connect one of the BLACK wires from solenoid to the RED positive

pump wire or the WHITE wire from the controller. Note that connecting

the wire to any other power source other then the pump/controller wire

will result in improper operation of solenoid. Connect the second BLACK

wire to a secure chassis ground location.

White from S3

Loading...

Loading...