Operating and maintenance instructions

ENGLISH 15

7.4 Air Filter Maintenance

Dirty air filters cause a reduction in engine

performance and increase fuel consumption with

more pollutants in the exhaust gas. Engines are

less likely to start readily with a dirty and soiled air

filter.

The following maintenance jobs should be carried

out frequently.

Before opening the air filter, close the choke

to

prevent dirt entering the carburettor.

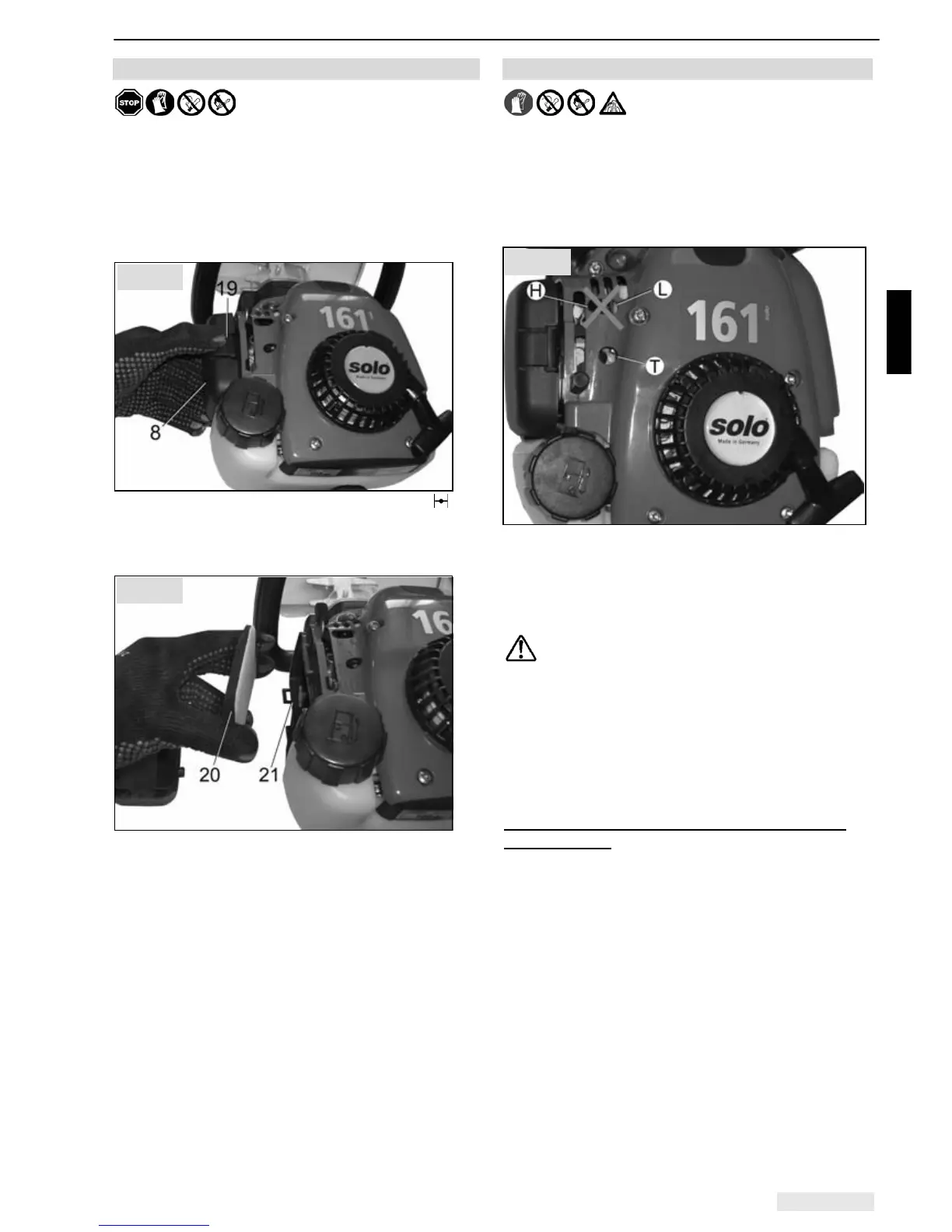

Press clip (19), tilt and remove the filter cover (8).

Clean around the filter.

Remove the assembled filter element (20) from the

filter retainer (21). Please note: Never separate

the filter element

Please note: Never separate the filter element.

Clean the filter more often in extreme dust

conditions. For daily cleaning jobs simply tap the

filters against a hard object or use compressed air.

Damaged air filters should be replaced

immediately. Warranty does not apply to engine

damage caused by the lack of or improper

maintenance.

Insert the new or cleaned filter element in

accordance with Fig. 16 into the filter retainer.

Then close the filter cover and secure it by clicking

it into position.

Never insert moist or wet filter elements!

7.5 Carburettor adjustment

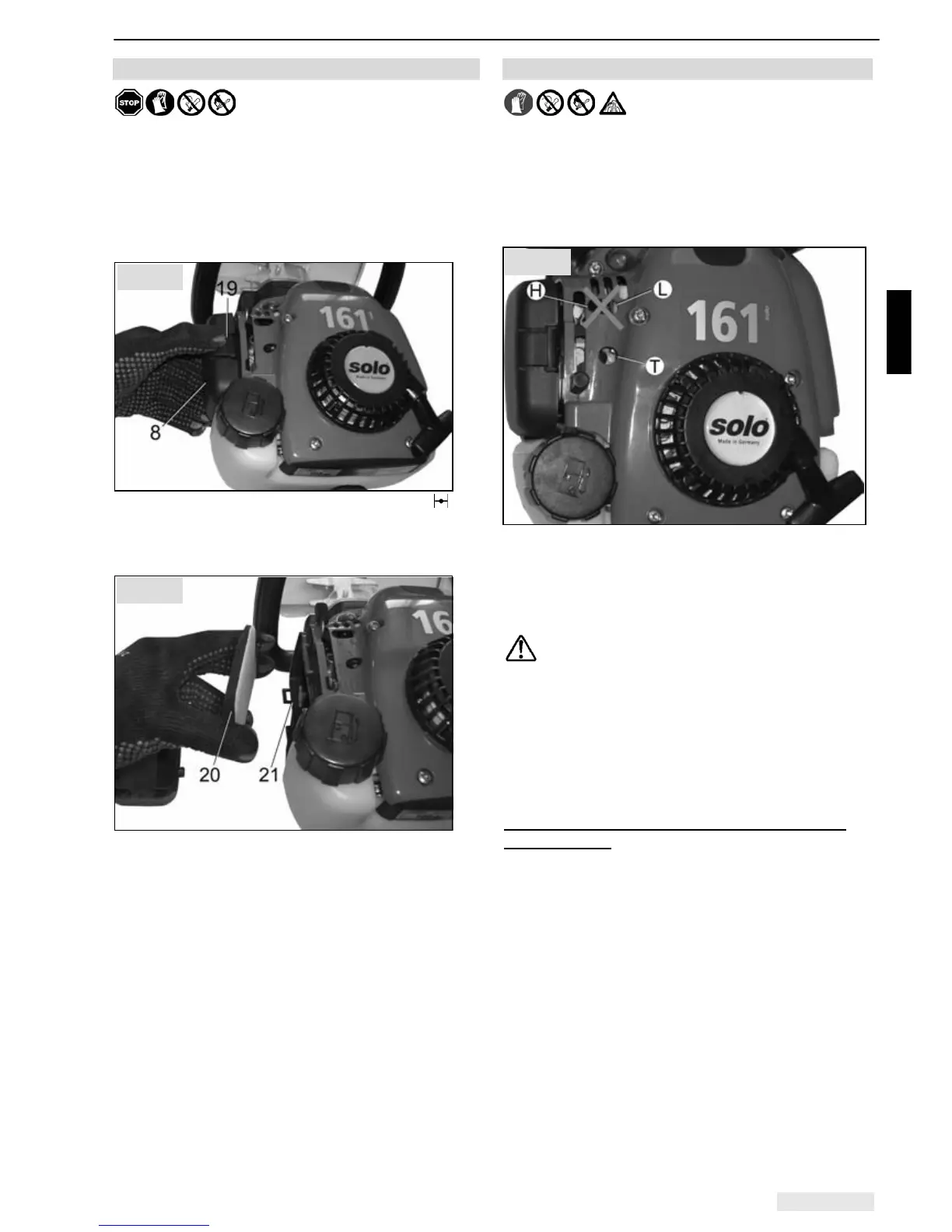

The carburettor is adjusted at the factory for

optimum performance. Subject to the place of use

(mountains, low-lying areas), the average idling

speed given in the specification can be adjusted as

follows, via the idling end-stop screw "T" (the use

of a rev counter is recommended):

• If the idling speed is too high, turn the idling

end-stop screw "T" anti-clockwise.

• If the idling speed is too low (engine stops) turn

the idling end-stop screw "T" clockwise until the

engine runs smoothly.

Under no circumstances must the cutter be

driven at idle speed.

If the idling speed cannot be set correctly with the

idling end-stop screw "T", request an authorised

service centre to tune the carburettor.

The adjusting screws for the idling mixture "L"

and the full-load mixture "H" must only be

adjusted by an authorised workshop.

The following instructions are for authorised

service shops

Use the D-CUT carburettor key to adjust the idle

mixture screw "L" and the full load mixture screw

"H".

Ask the specialist workshop that is part of our

customer service about standard settings, or visit

our internet portal for dealers at www.part-and-

more.org.

Clean the air filter before adjusting the low speed

screw!

Let the engine run warm before adjusting the

engine speed.

The carburettor is tuned for optimum engine

performance. Use a rev counter to tune the

carburettor correctly!

Do not adjust the engine to a higher speed.

Excessive engine speed can lead to major engine

damage!

Fig. 17

Fig. 15

Fig. 16

Loading...

Loading...