Operating and maintenance information

ENGLISH 18

Before you can fit a new saw chain you must check the

condition of the sprocket. Worn sprockets will damage

your new saw chain. If necessary, replace the sprocket

with the new chain. Grease the bearing with lithium-

based grease whenever the sprocket is replaced.

Tip: We recommend the use of two saw chains per

sprocket, and that both chains should be replaced as

frequently as possible so that all of the components

wear evenly. Once a certain wear limit is reached,

replace all of the parts together again.

To replace the chain wheel (after dismantling the guide

bar cover and the guide bar with chain), push the chain

wheel with its washer down slightly and lift off the

locking ring with a small screwdriver.

To refit the locking ring after fitting the new chain wheel

push the chain wheel, with its washer, down again

slightly.

Guide bar:

The guide bar of your

chainsaw requires just as

much care as the saw

chain. The running surfaces

must be flat and level, and

the groove must not be

widened.

In order to prevent one-sided wearing of the guide bar,

we recommend that the guide bar be reversed

whenever the chain is sharpened.

On guide bars with a guide

sprocket, the bearing of the

guide sprocket should

preferably be lubricated with

ball bearing grease (through

the lubricating hole on the side with a grease gun)

every time the chainsaw is refuelled. Rotate the guide

sprocket while doing this.

Important: The guide bars are only designed to guide

the saw chain and must not be used as a levering tool.

Any twisting or turning or use of the guide bar to gain

leverage in the wood shortens the service life of the

guide bars.

11.2 Air Filter Maintenance

Contaminated air filters cause a reduction in engine

performance and increase fuel consumption with more

pollutants in the exhaust gas. Engines are less likely to

start readily with a contaminated air filter.

When using the power tool all day, clean the air filter

daily; under very dusty conditions, even several times a

day.

Carry out the following maintenance jobs regularly.

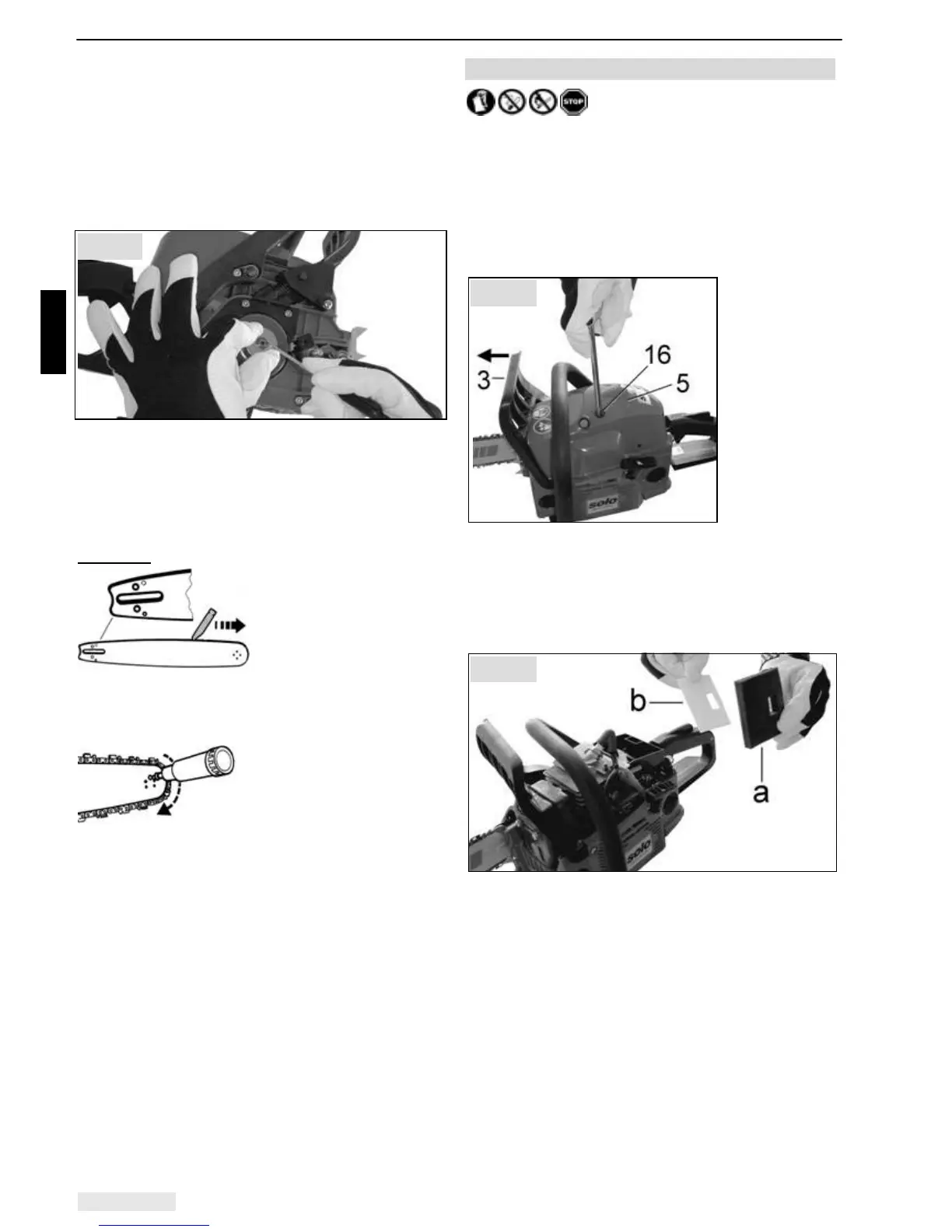

To prevent dirt from entering the carburettor inlet,

always pull out the choke lever (7) prior to removing the

hood (5). To make the hood removal easier (and the

subsequent replacement), it is recommended to push

the hand guard (3) forward (chain brake activated).

Undo the fixing screw (16) completely (screw is retained

inside the hood) and remove the hood (5).

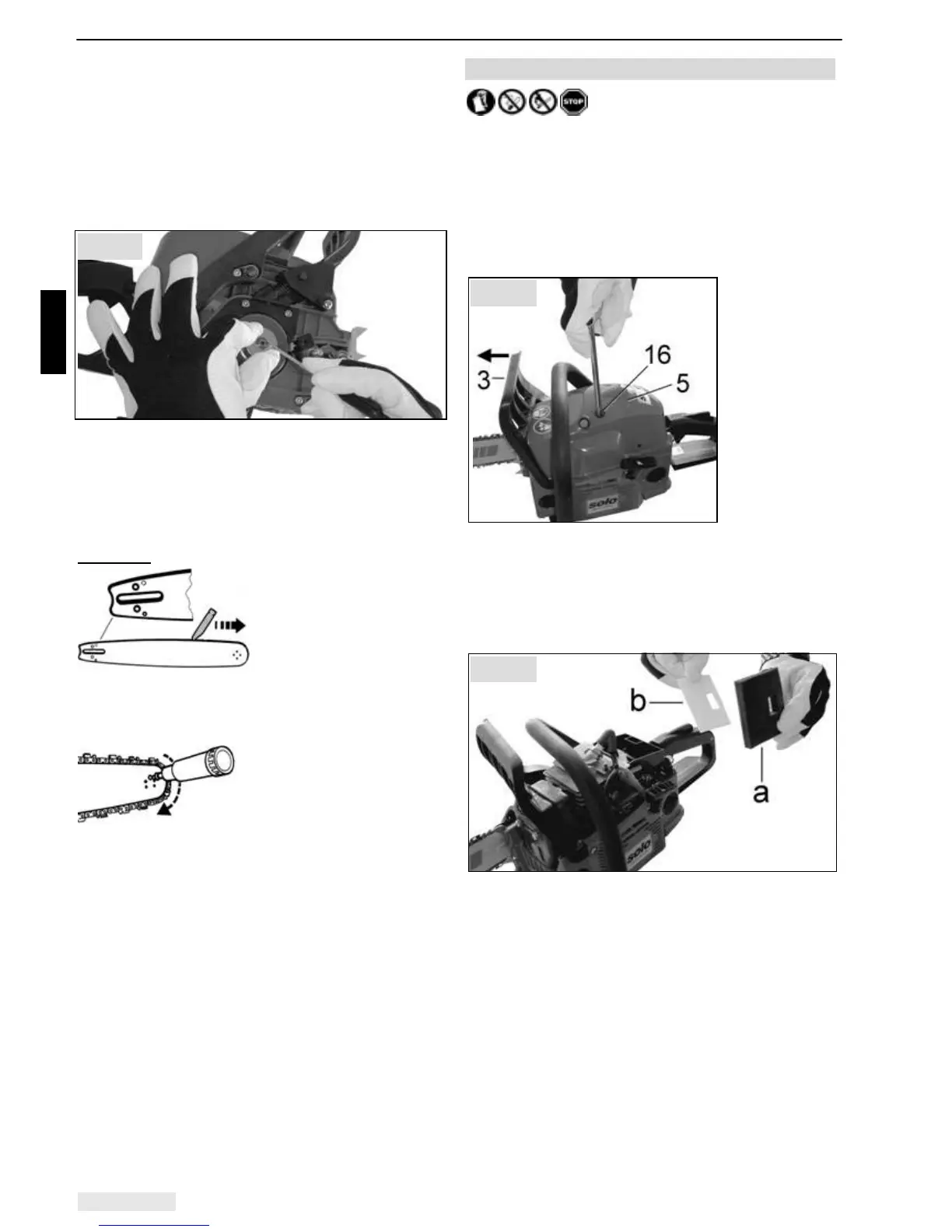

Remove the foam filter (5) and the flow filter insert (b).

The best way to clean the filter is to simply tap out any

dirt or blow it out with a blast of air.

If they are more heavily contaminated, both filters can

be cleaned with non-flammable cleaning fluid (warm

soapy water). Both filters must be absolutely dry before

they are refitted to the device.

The corresponding parts should be replaced

immediately if the filter material is damaged. No

warranty claims can be accepted for engine damage

arising as a result of inadequate care.

Dry out the area surrounding the filter and remove all

dust residues. First introduce the flow filter insert, then

the foam filter.

When positioning the hood, ensure that it fully locks all-

round into the groove of the main casing.

Fig. 16

Fig. 17

Fig. 18

Loading...

Loading...