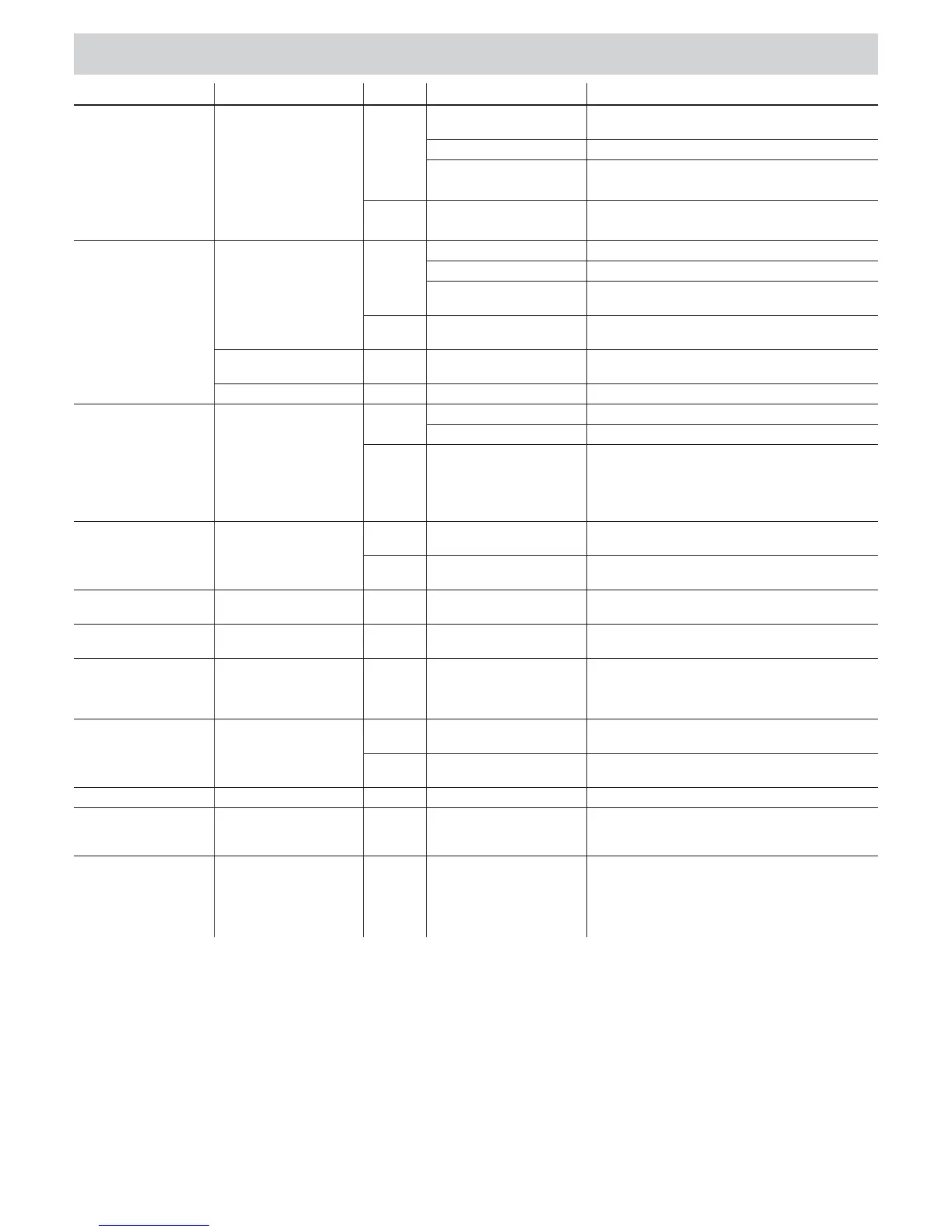

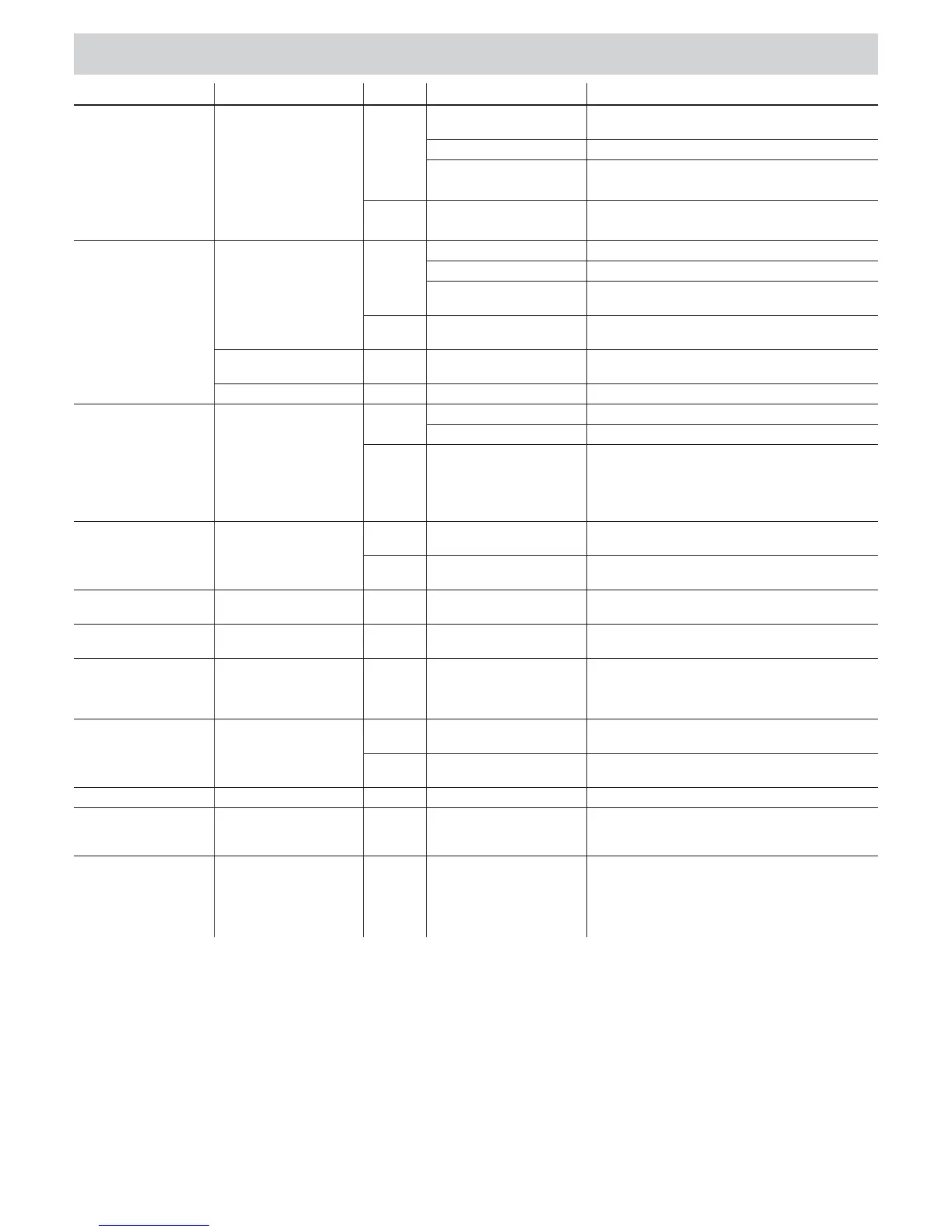

Troubleshooting

32

Fault Control Yes/No Possible cause Remedy

Gate cannot be opened

or closed with a

connected key switch.

“Mains + Start 1/Start 2”

LEDs on?

Yes Cable connections

interrupted?

Tighten terminal.

Key switch defective. Replace key switch.

Permanent contact due

to damaged wire insulation.

• Check wiring.

• Replace damaged cables.

No Pulse transmitter

(key switch) defective.

• Check pulse generator.

• Replace defective pulse generator.

Gate remains stationary

and reverses during

opening and closing.

Is there an obstacle

outside the range

of motion?

No Hinges stiff. Lubricate hinges.

Post or pillar has changed. Align posts/pillars.

Limit switch out of

adjustment.

Adjust limit switch.

Yes Power deactivation

tripped.

Remove obstacle.

Does the gate leaf vibrate

when moving?

Yes Gate leaf unstable. Reinforce gate leaf.

Strong wind load? Yes Wind pressure too strong. Open and close gate again.

Gate remains stopped

when opening.

Photo eye interrupted? Yes Obstacle in light beam. Remove obstacle.

Photo eye soiled. Clean the photo eye.

No Connection for external

consumers overloaded

(terminals 9 +10).

Voltage drop when operator

starts.

• Observe maximum connection power.

• Only connect suitable tools.

Gate does not open

or close completely.

Does the gate stop before

the set end position?

No Gate fi ttings not installed

correctly.

Change the gate bracket.

Yes Limit switch incorrectly

adjusted.

Adjust limit switch.

Closing sequence

incorrect.

Operators incorrectly

connected.

Connect operators as specifi ed in the manual.

Operator does not learn

the force values.

DIP switch 8 to OFF. Set DIP switch 8 to ON.

Gate does not stop

at an obstacle.

Gate in learning mode.

DIP switch 8 to ON.

Force tolerance too high.

• After learning mode the power cut-off responds.

• Set DIP switch 8 to OFF.

• Reduce force tolerance.

Operator stops at pillar. Are the A/B dimensions

correct?

No A or B dimension

not correct.

Adjust fastening of operator to post or pillar.

Yes Limit switch out

of adjustment.

Adjust limit switch.

Gate moves unevenly. A/B dimensions unequal. Change installation dimension.

Walk-through gate does

not open

with transmitter.

Hand-held button not

programmed.

Program button.

Operators do not start. Does “SH” LED fl ash

quickly?

Yes Jumper was moved with

programmed force values.

• Place jumper in previous position.

• Reset the control unit.

• Replug jumpers.

• Perform learning runs.

* If photo eye is uninterrupted, the operator can be moved in dead man mode with the “Open” and “Close” buttons. If an obstacle is detected,

power deactivation also occurs in this operating mode.

Additional support during troubleshooting

When the troubleshooting tips are not successful, take the following measures:

• Reset the control units (delete force values).

• Disconnect the connected accessories (e.g. photo eye) and use wire bridges again.

• Set all DIP switches to the factory setting.

• Turn potentiometer to the factory setting.

• If settings have been changed using TorMinal, perform the control unit reset with TorMinal.

Dealers offer additional support during troubleshooting and elimination of faults.

Loading...

Loading...