— 38 —

DV MECHANICAL ADJUSTMENT MANUAL VII

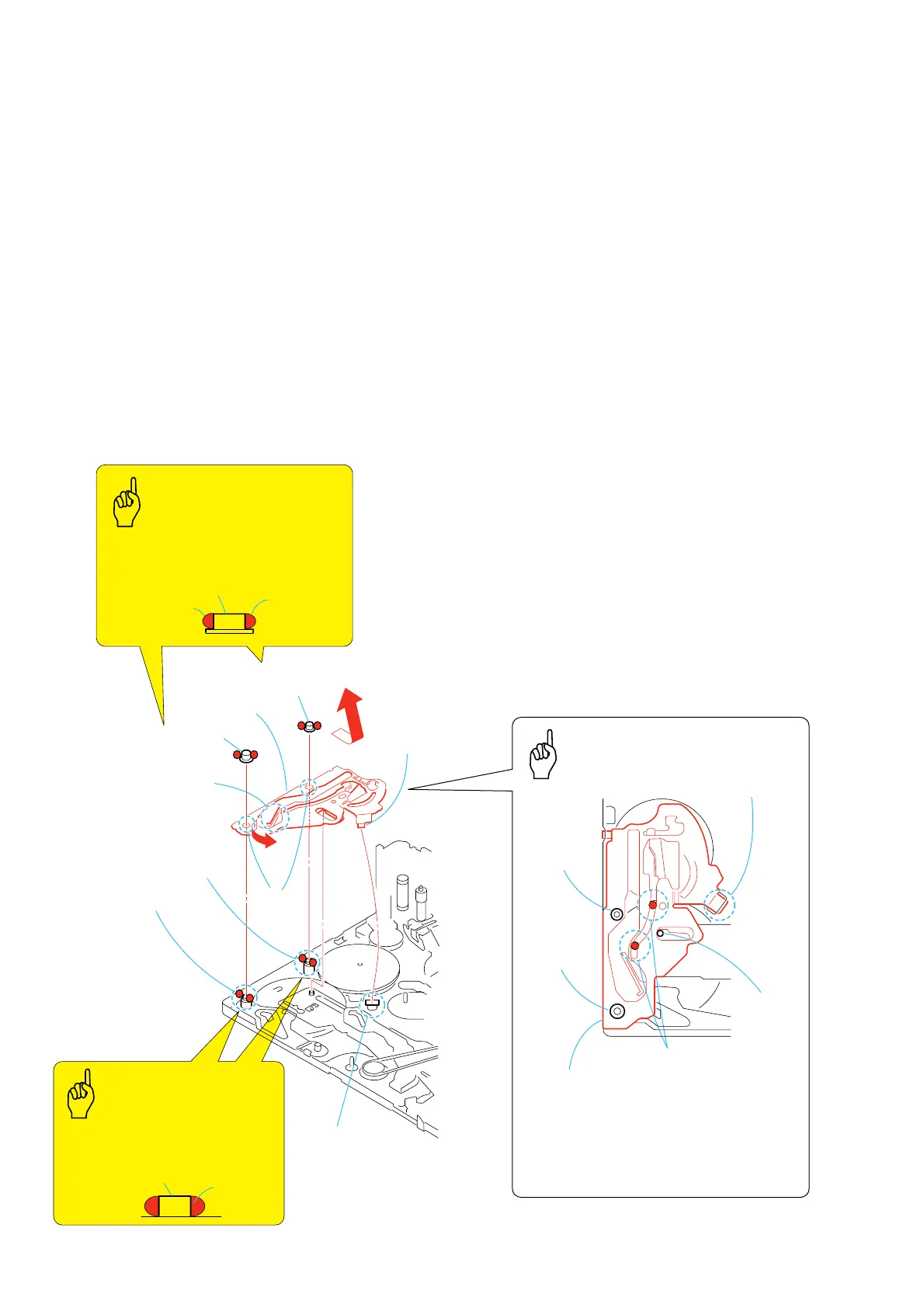

3-27.TG2 Cam Plate Assy

1. Removal procedure

1) Remove the LS guide roller (S1) 1 from the S1 shaft.

2) Remove the LS guide roller (S2) 2 from the S2 shaft.

3) Release the claw A of the TG2 cam plate assy 3 from the

right groove B of the mechanical chassis.

4) Remove the TG2 cam plate assy 3 in the direction of the arrow

C.

2. Attachment procedure

1) Move the brake driving arm of the TG2 cam plate assy 3 in

the direction of the arrow D.

2) Insert the right claw A of the TG2 cam plate assy 3 into the

right groove B of the mechanical chassis first.

3) Install the two round holes E of the TG2 cam plate assy 3

into the S1 shaft and the S2 shaft.

4) Apply grease in the F portion of the TG2 cam plate assy.

Amount of grease: a ball of 1.0 mm diameter of grease

5) Apply grease to both sides of the S1 shaft and the S2 shaft.

Amount of grease: a ball of 1.0 mm diameter of grease

6) Apply grease to both sides of the LS guide roller S1, S2.

7) Install the LS guide roller S1 1 in the S1 shaft.

8) Install the LS guide roller S2 2 in the S2 shaft.

3

TG2 cam

plate assy

1

LS guide roller S1

LS guide roller S1, S2

2

LS guide

roller S2

Brake driving arm

C

D

F

S2 shaft

S2 shaft

S1 shaft

M slider shaft

S1 shaft

S1 shaft, S2 shaft

Apply grease when installing it

Amount of grease: a ball of

1.0 mm diameter of grease

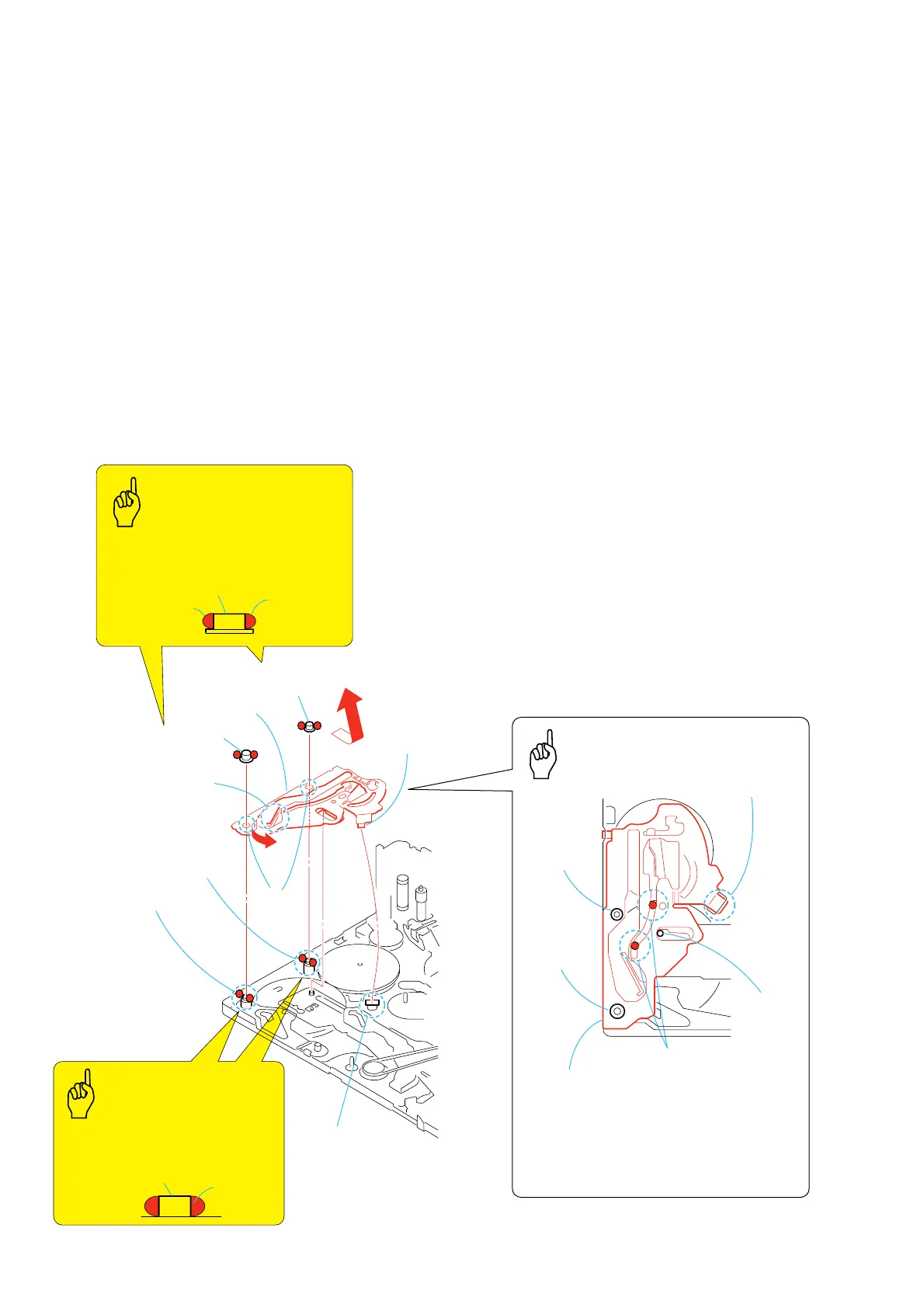

Claw

A

Two round

holes

E

Claw

A

Groove

B

TG2 cam

plate assy

Apply grease

Apply grease

Apply grease

Apply grease when installing it.

Amount of grease: a ball of 1.0 mm

diameter of grease

Apply grease when installing it.

Amount of grease: a ball of 1.0 mm

diameter of grease

TG2 CAM PLATE ASSY

The Points

in Re-assembling

Points to be noted

Points to be noted

• Confirm that the M slider shaft has entered in the

groove of the brake driving arm surely.

• Confirm that the right and left claws of the TG2

cam plate assy

3

have entered into the

mechanical chassis surely.

Apply Grease

Apply Grease

Loading...

Loading...