Registered Quality System to ISO 9001 | 913-888-2630 | SORInc.com

8/16

Form 281 (05.18) ©SOR Inc.

Adjustable Dead Band

Pressure Switches

Step 4: Diaphragm and O-Ring

5V1-LA3-N6-C1A-YY

Notes

1. N4 diaphragm system is standard. It is

normally suitable for air, oil, water and non-

corrosive processes.

2. Other diaphragm and o-ring combinations

may be available. Consult the factory or the

SOR representative in your area for more

information.

3. Wetted parts have been selected as repre-

senting the most suitable commercially

available material for use in the service

intended. However, they do not constitute a

guarantee against corrosion or permeation,

since processes vary form plant to plant and

concentration of harmful fluids, gases or

solids vary from time to time in a given

process. Emperical experience by users

should be the final guide. Alternate materials

based on this are generally available.

4. Specify N3 diaphragm system for high cycle

rate, high shock applications where Buna-N

and TCP are compatible with the process.

5. This table shows allowable minimum and

maximum temperature for o-rings.

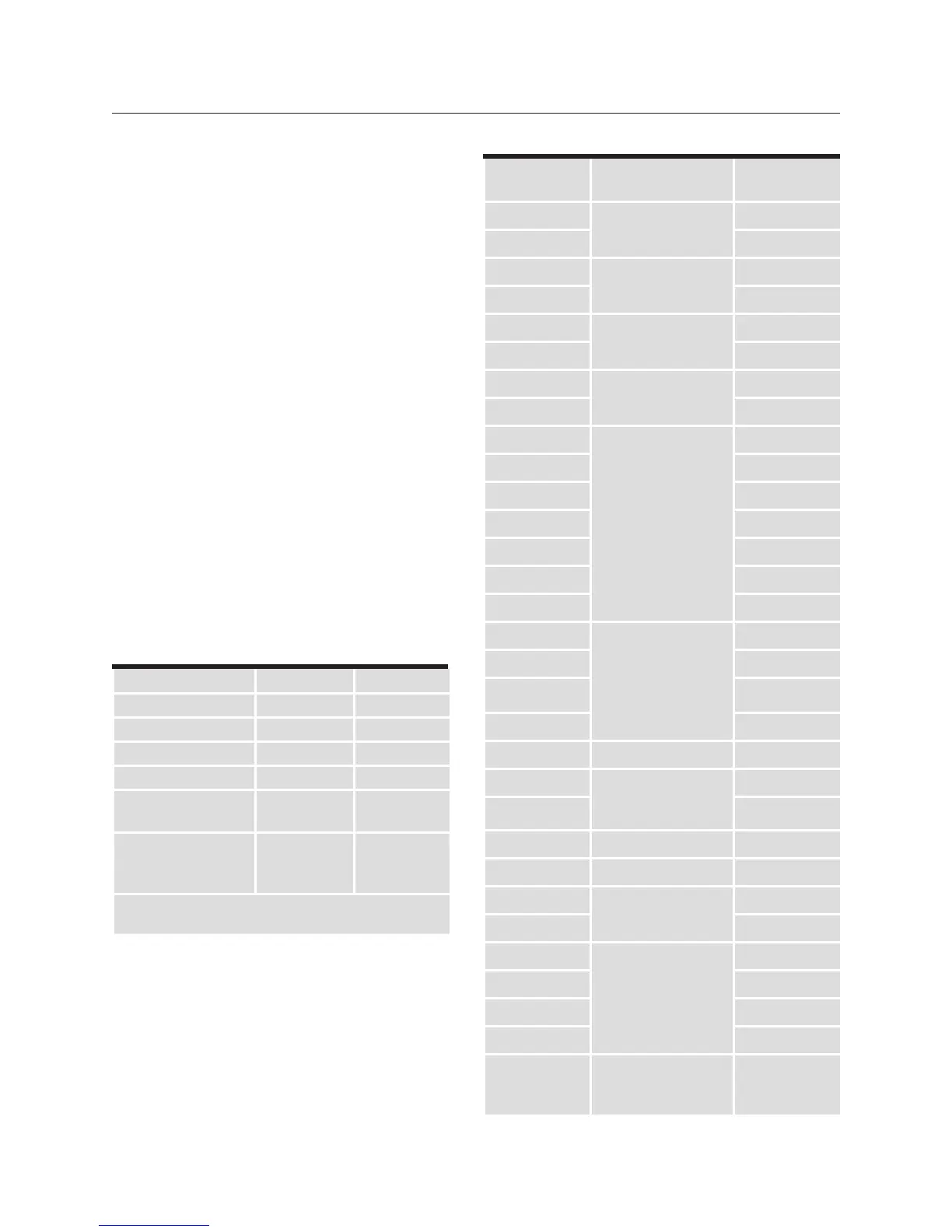

O-Ring

(Wetted)

Diaphragm

(Wetted)

Designator

Viton

Monel

A4

Kalrez A6

Viton

Hastelloy-B

H4

Kalrez H6

Viton

Hastelloy-C

J4

Kalrez J6

Viton

Carpenter-20

L4

Kalrez L6

Viton GLT

316L SS

M1

Buna-N M2

Viton M4

Neoprene M5

Kalrez M7

Aflas M8

EPR M9 Note 6

Viton

TCP

Teflon-Coated

Polyimide

N1

Buna-N N3 Note 4

Buna-N

N4 Standard

Note 1

Kalrez N5

Kalrez Kalrez N6

EPR

TCP

Teflon-Coated

Polyimide

N7

Aflas N8

Buna-N Buna-N P1

Neoprene Neoprene R1

Viton

Viton

S1

Viton GLT S2

Buna-N

Tantalum

W2

Viton W4

Neoprene W5

Kalrez W6

EPR

Ethylene

Propylene

EPR

Ethylene Propylene

Y1

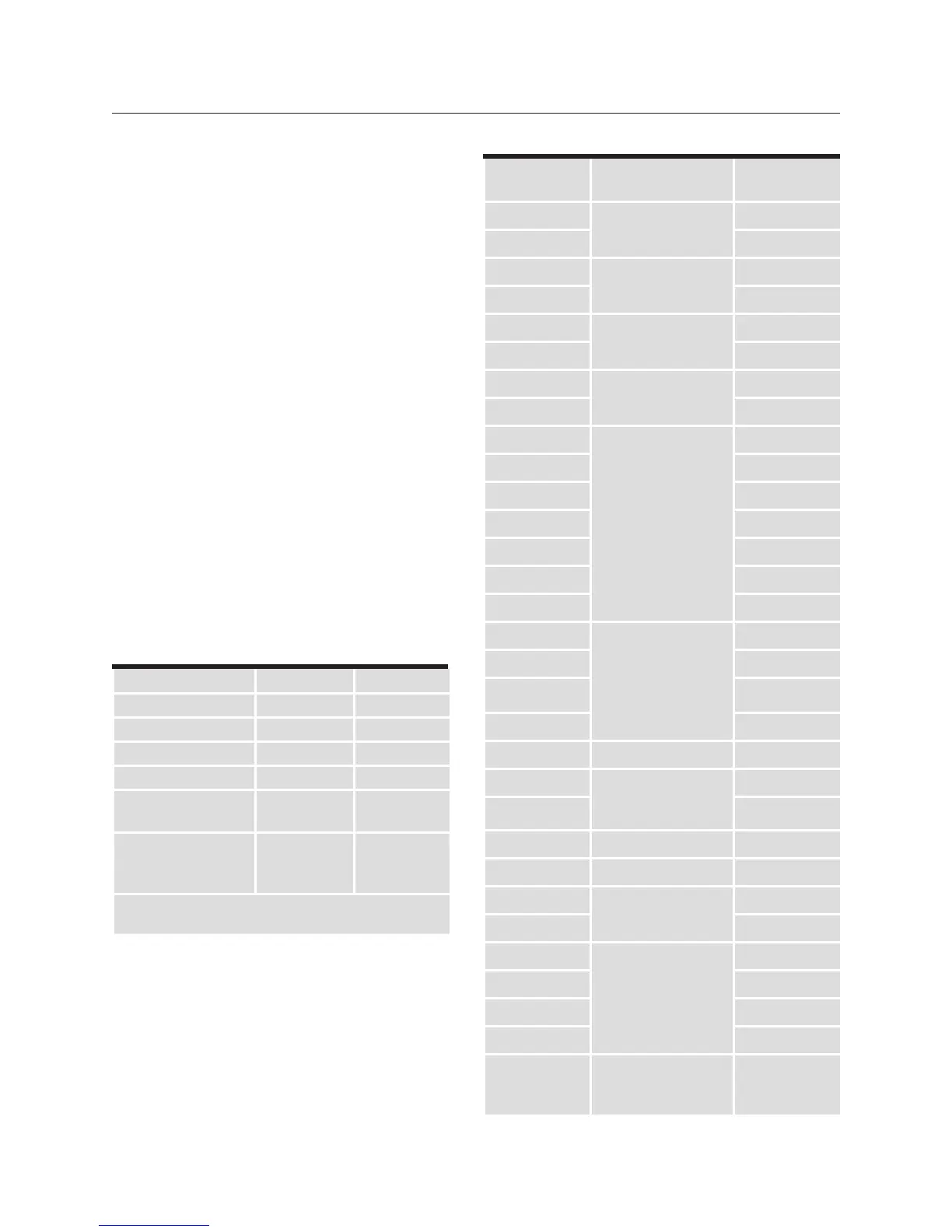

O-Ring Material ° F ° C

Viton 32 to 400 0 to 204

Viton GLT -20 to 400 -29 to 204

Kalrez* 5 to 400 -15 to 204

Aflas 25 to 400 -4 to 204

Buna-N

Neoprene EPR

-30 to 200 -34 to 93

TCP Teflon Coated

Polyimide

Diaphragm

-30 to 400 -34 to 204

*Kalrez or equivalent

Perfluoroelastomer (FFKM) o-rings

6. M9 diaphragm system is suggested for

steam applications up to 400

o

F.

7. Dead bands are slightly higher when using

H, J, W, N3, or N6 series diaphragm options.

Consult the factory.

Loading...

Loading...