System

Descriptions: SORVALL®

Centrifuges

Electrical

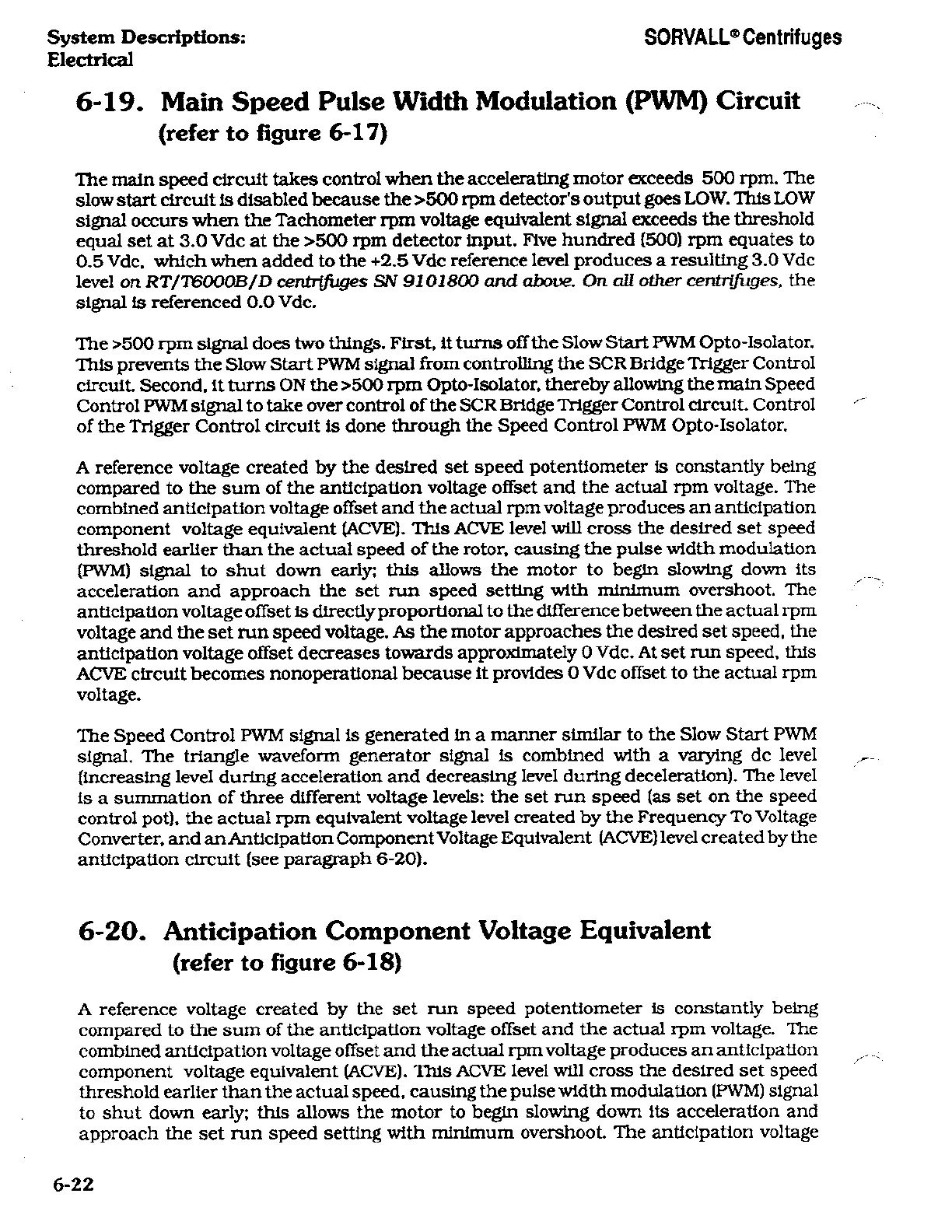

6-19. Main

Speed

Pulse

Width

Modulation (PWM)

Circuit

(refer

to

figure

6-17)

The

main

speed

circuit takes control

when

the

accelerating motor exceeds

500

rpm.

The

slow

start circuit

Is

disabled

because

the

>500

rpm

detector's

output

goes

LOW.

This

LOW

signal

occurs

when

the

Tachometer

rpm

voltage equivalent

signal exceeds

the

threshold

equal

set

at

3.0

Vdc

at

the >500

rpm

detector

input.

Five

hundred

(500)

rpm

equates

to

0.5 Vdc.

which

when added

to

the

+2.5

Vdc

reference

level

produces

a

resulting

3.0

Vdc

level

on

RT/T6000B/D

centrifuges

SN 9101800

and

above.

On

all

other

centrifuges,

the

signal

is referenced

0.0 Vdc.

The

>500

rpm

signal

does two

things.

First,

it

turns

off the Slow

Start PWM

Opto-Isolator.

This

prevents

the Slow Start

PWM

signal

from

controlling

the

SCR

Bridge

Trigger

Control

circuit.

Second,

it

turns

ON

the >500

rpm

Opto-Isolator, thereby allowing

the

main Speed

Control

PWM

signal

to

take over

control

of the

SCR

Bridge Trigger

Control

circuit.

Control

of

the

Trigger

Control circuit

is

done through

the

Speed

Control

PWM

Opto-Isolator.

A

reference voltage

created

by

the desired set

speed

potentiometer is constantly being

compared

to

the

sum

of

the

anticipation voltage onset

and

the

actual

rpm

voltage.

The

combined

anticipation

voltage

offset and

the

actual

rpm

voltage produces an

anticipation

component voltage equivalent

(ACVE).

This ACVE

level

will

cross

the

desired set

speed

threshold

earlier than

the

actual

speed

of the

rotor,

causing

the

pulse

width modulation

(PWM)

signal

to

shut

down

early;

this

allows

the

motor

to

begin slowing

down its

acceleration and

approach

the

set run

speed

setting

with

minimum

overshoot.

The

anticipation

voltage

offset Is

directly proportional to

the difference

between

the

actual

rpm

voltage

and

the

set run

speed voltage.

As

the

motor

approaches

the

desired

set

speed,

the

anticipation

voltage

offset

decreases

towards

approximately

0

Vdc.

At

set

run

speed,

this

ACVE

circuit becomes

nonoperatlonal

because

it

provides

0 Vdc

offset

to

the actual

rpm

voltage.

The

Speed

Control

PWM

signal

is

generated

in

a

manner

similar

to

the

Slow Start

PWM

signal.

The

triangle waveform

generator

signal

is combined

with

a varying

dc

level

(Increasing

level

during

acceleration and

decreasing

level

during deceleration).

The

level

is

a

summation

of three different

voltage

levels:

the

set run speed (as set on

the

speed

control

pot),

the

actual

rpm

equivalent

voltage

level created

by

the

Frequency

To

Voltage

Converter,

and

an Anticipation Component

Voltage Equivalent

(ACVE)

level created

by

the

anticipation

circuit

(see

paragraph

6-20).

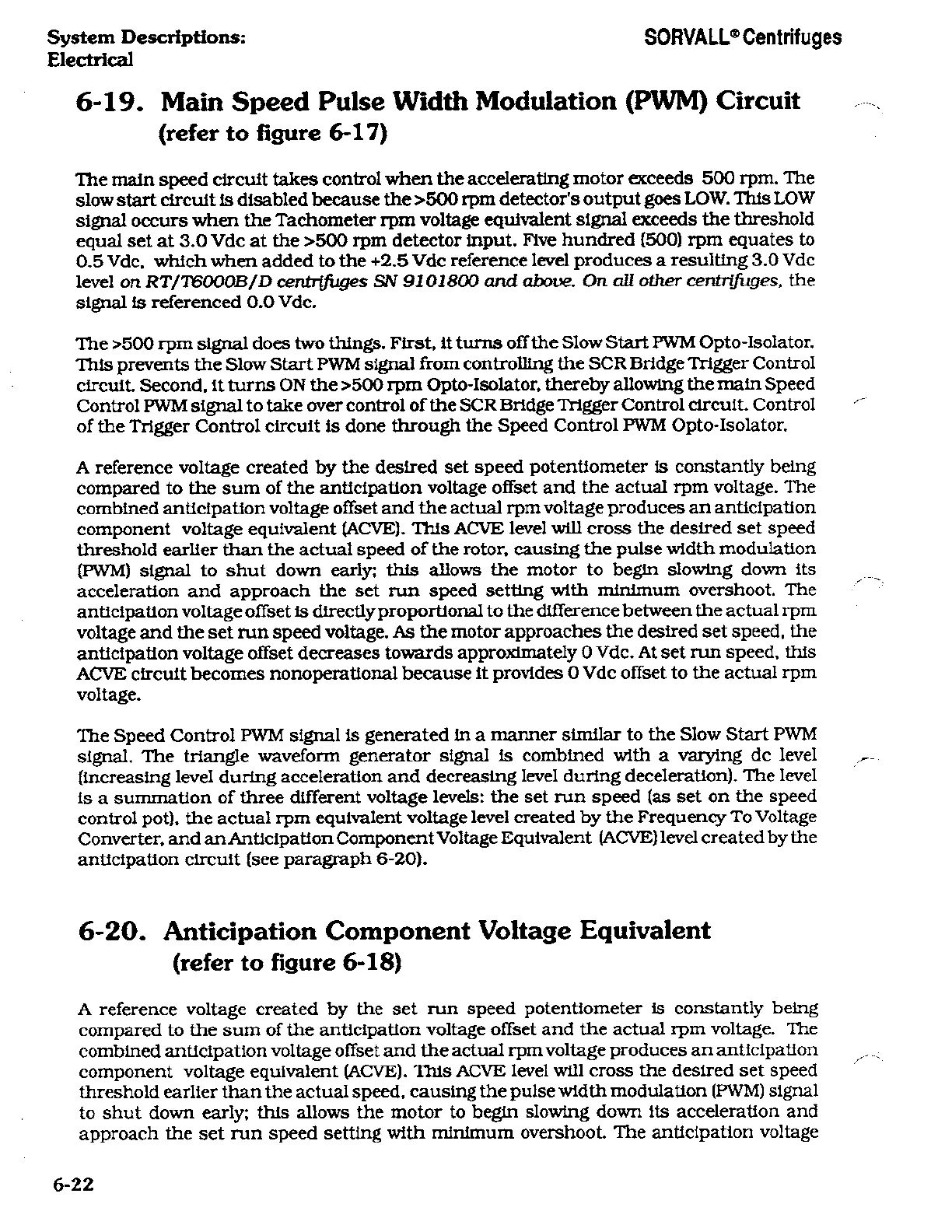

6-20.

Anticipation

Component

Voltage Equivalent

(refer

to

figure

6-18)

A

reference voltage

created

by

the

set run

speed

potentiometer

is

constantly being

compared

to

the

sum

of

the

anticipation voltage

offset and

the

actual

rpm

voltage.

The

combined anticipation

voltage

offset and

the

actual

rpm

voltage produces an

anticipation

component

voltage equivalent

(ACVE).

This ACVE

level

will

cross

the

desired

set speed

threshold earlier than

the

actual

speed,

causing

the

pulse

width

modulation

(PWM)

signal

to shut down

early;

this

allows

the

motor

to

begin slowing

down

its

acceleration

and

approach

the

set

run

speed

setting

with

minimum overshoot.

The

anticipation voltage

6-22

Loading...

Loading...