General Maintenance VirTis BenchTop 2K, 4K and 6K

38 Revision 004, 12/09

Condenser Chamber

The condenser is fabricated from stainless steel. Under normal use, it can be rinsed

and kept clean with a mild detergent. If corrosive materials are being freeze-dried,

thoroughly clean and rinse all parts of the freeze dryer that come in contact with

product vapor. This prevents build-up of corrosive materials, which protects the freeze

dryer and subsequent product loads. Add baking soda or a mild buffering agent to the

rinse water to help neutralize acidic residue. A siphon type squeeze bottle can be

used to direct the rinse spray into difficult to reach areas.

For more information, refer to Appendix C: Stainless Steel Cleaners.

Acrylic Parts

Clean acrylic covers and manifolds with a mild detergent. Use a soft cloth or

Kimwipes® to avoid scratching the acrylic.

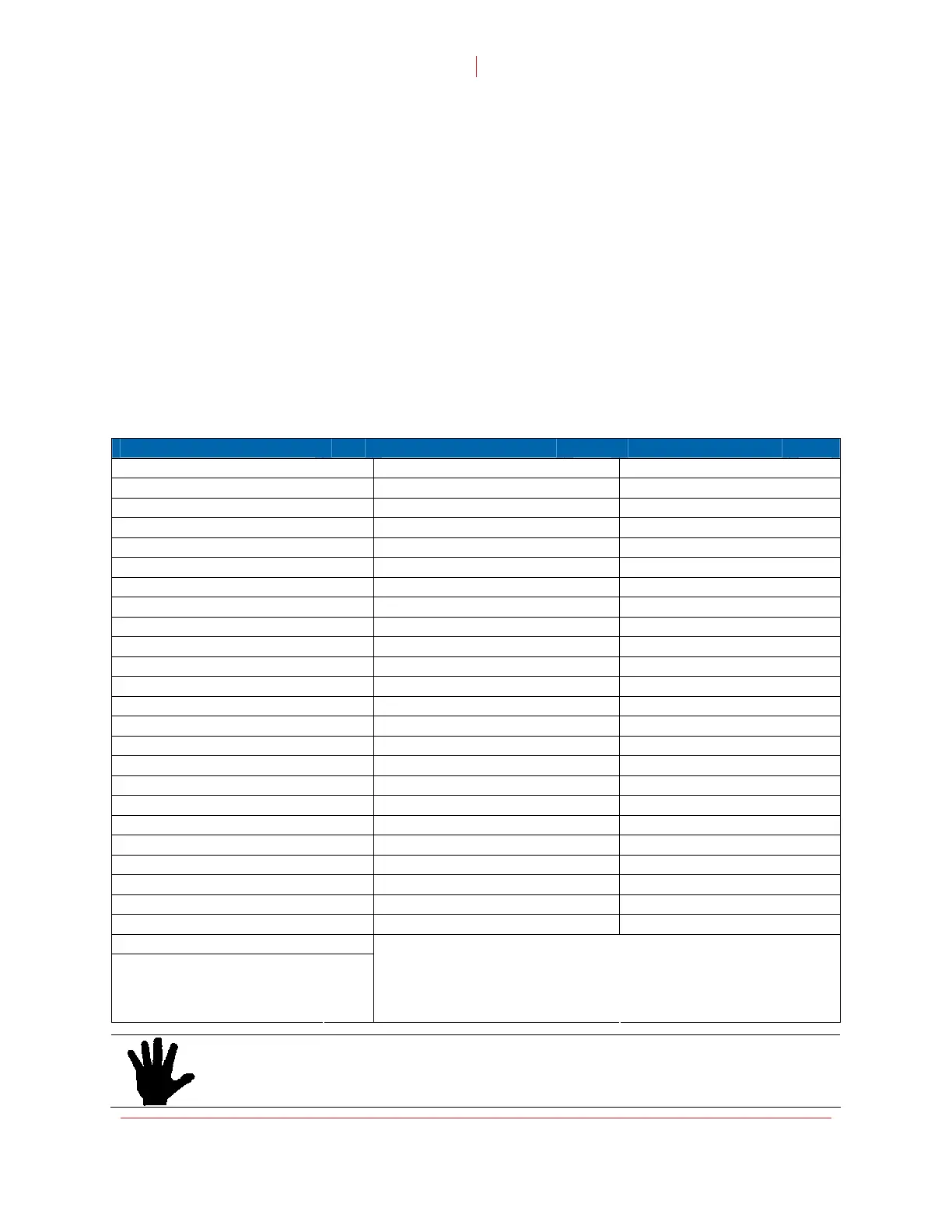

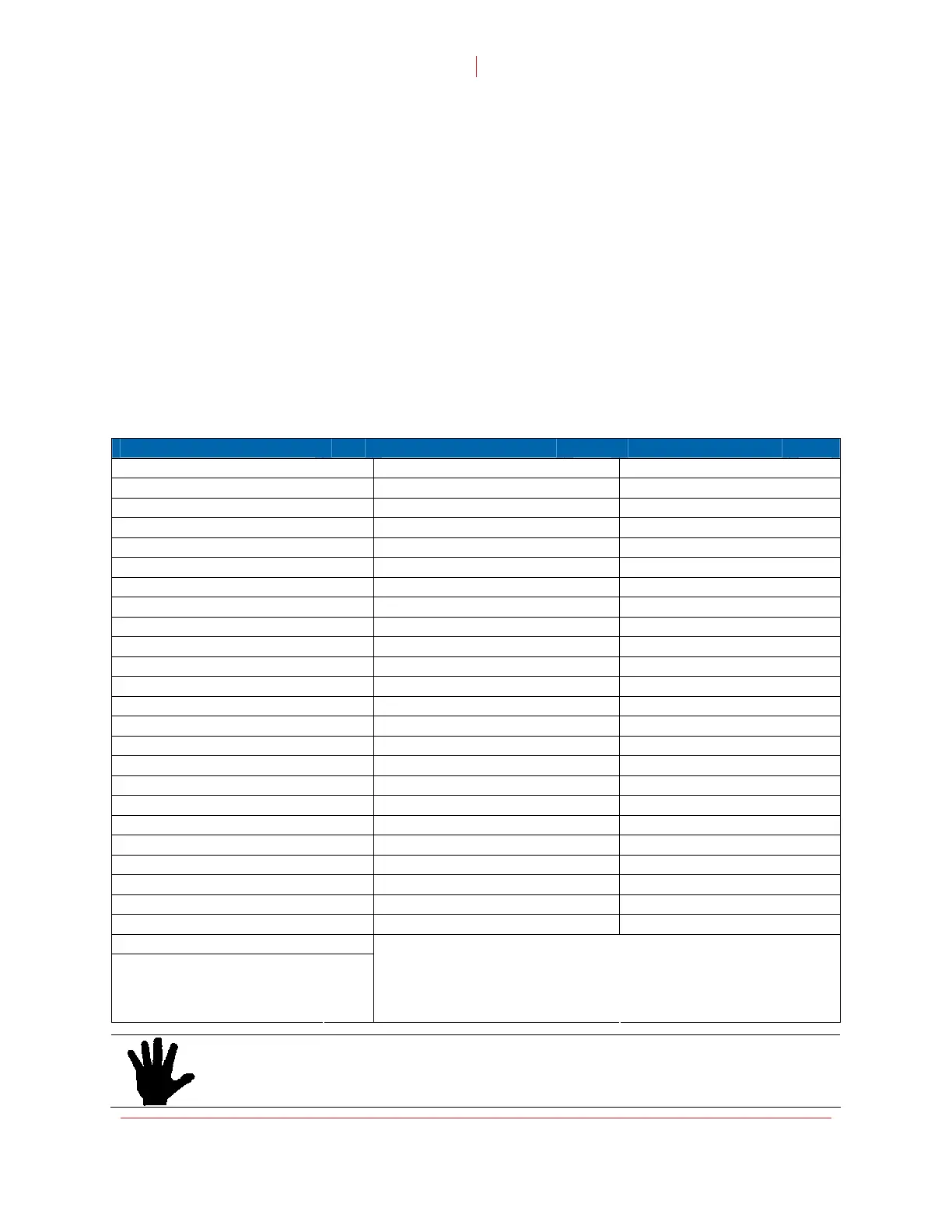

The following table may be used as a general guide to acrylic’s chemical resistances.

Chemical Code Chemical Code Chemical Code

Acetic Acid (5%) R Ethyl Alcohol (50%) LR Nitric Acid (10%) R

Acetic Acid (Glacial) N Ethyl Alcohol (95%) N Nitric Acid (40%) LR

Acetic Anhydride LR Ethylene Dichloride N Nitric Acid (Conc.) N

Acetone N Ethylene Glycol R Oleic Acid R

Acetonitrile N 2-Ethylhexyl Sebacate R Olive Oil R

Ammonium Chloride (Saturated) R Formaldehyde (40%) R Phenol Solution (5%) N

Ammonium Hydroxide (10%) R Gasoline (Regular, Leaded) LR Soap Solution (Ivory) R

Ammonium Hydroxide (Conc.) R Glycerine R Sodium Carbonate (2%) R

Aniline N Heptane R Sodium Carbonate (20%) R

Battery Acid R Hexane (Commercial Grade) R Sodium Chloride (10%) R

Benzene N Hydrochloric Acid N Sodium Hydroxide (1%) R

Benzyl Alcohol N Hydrofluoric Acid (40%) R Sodium Hydroxide (10%) R

Butyl Acetate N Hydrogen Peroxide (3%) R Sodium Hydroxide (60%) R

Calcium Chloride (Sat.) R Hydrogen Peroxide (28%) N Sodium Hypochlorite (5%) R

Calcium Hypochlorite R Isooctane R Sulfuric Acid (3%) R

Carbon Tetrachloride N Isopropyl Alcohol LR Sulfuric Acid (30%) R

Chloroform N Kerosene R Sulfuric Acid (Conc.) N

Chromic Acid (40%) N Lacquer Thinner N Toluene N

Citric Acid (10%) R Methyl Alcohol (50%) LR Transformer Oil R

Cottonseed Oil (Edible) R Methyl Alcohol (100%) N Trichloroethylene N

Detergent Solution (Heavy Duty) R Methyl Ethyl Ketone (MEK) N Turpentine LR

Diesel Oil R Methylene Chloride N Water (Distilled) R

Diethyl Ether N Mineral Oil R Xylene N

Dimethyl Formamide N Naphtha (VM&P) R Trifluroacetic Acid N

Dioctyl Phthalate N

Ethyl Acetate N

Codes:

R = Resistant (withstands long periods

of exposure at temperatures up to 50 °C)

LR = Limited Resistance

(withstands short periods of

exposure at room temperature)

N = Not Resistant (immediate

damage may occur upon exposure)

CAUTION! DO NOT USE ORGANIC SOLVENTS OR ABRASIVE CLEANERS.

© SP Industries, Inc. 2009

Loading...

Loading...