– 16 –

Model SCM Air to Water Heat Pump — Installation, Operation & Maintenance Manual

Section 8: Start-up and Test (continued)

Anti-freeze cycle

1. Should the water temperature drop to 34°F during periods

of non-use, the pump will start and the antifreeze heater (if

connected) will energize and continue to operate until the

temperature reaches 38°F.

2. If the water temperature continues to fall and reaches 33°F,

the Alarm symbol and Fault Code AL will be displayed,

and the unit will automatically start in heating mode. It will

continue to run until the water temperature reaches 38°F.

3. NOTE: This provides the maximum level of protection in all

cases, but may use energy unnecessarily when a suitable

concentration of glycol anti-freeze is installed. When freeze

protection is sufcient, these value can be adjusted to

lower temperatures. Contact technical support for guidance

in re-conguring these parameters, however it must be

understood that the installer is responsible for ensuring

sufcient freeze protection to the lowest temperature allowed.

24-Hour follow-up

Approximately 24 hours after start-up and testing, return to the

installation to verify proper operation. Perform the following

checks.

1. Check system pressure. Add additional glycol/water mixture

if needed to restore pressure. (Pressure can drop as air is

removed from the system by the air vents.)

2. Sample the glycol/water mixture in the system. Verify inhibitor

and glycol levels.

3. Inspect the piping and components to ensure there are no

leaks. Repair any leaks immediately.

4. Close the isolation valves on either side of the y-strainer at

the SpacePak heat pump return connection. Remove the

screen and inspect for sediment. Clean if necessary.

• If the strainer has become clogged with sediment, determine

whether the system needs to be drained, cleaned and re-

lled. Excessive sediment accumulation in the strainer will

reduce ow and cause the unit to shut down.

5. Cycle the system on heating and cooling. Verify that all

components operate correctly.

Electric Heat

The SCM series heat pumps are equipped with integral 3 kW

electric heater elements contained within the water circuit. These

are powered by a 230VAC input (separate from the heat pump

power) and must have individual protection, (minimum 15A)

The heater function is managed by the Carel μC2 controller, and

it provides three different functions, all of which are adjustable

via the Display Keypad.

A. Freeze protection: When the heat pump is in standby,

it monitors the temperature of the water circuit. If the

temperature falls below the value of parameter A04, the

controller will start the circulator, and send a call for the

heaters to energize. The heaters are powered through a Time

Delay Relay (TDR), to ensure ow is established before the

heaters come on. Parameter A05 is a differential value, such

that the heaters will shut off when the temperature reaches

A04 + A05.

B. Heat boost: When the heat pump is operating in heating

mode, the Carel controller will call for the heater to be

energized when the water temperature falls below the value

of parameter A08, again controlled by the TDR. Parameter

A09 is a differential value, such that the heaters will shut off

when the temperature reaches A08 + A09.

C. Defrost operation: When enabled, via parameter d11 being set

to a value of 01, the controller will call for the heater to energize,

after the TDR duration, whenever the defrost cycle is active.

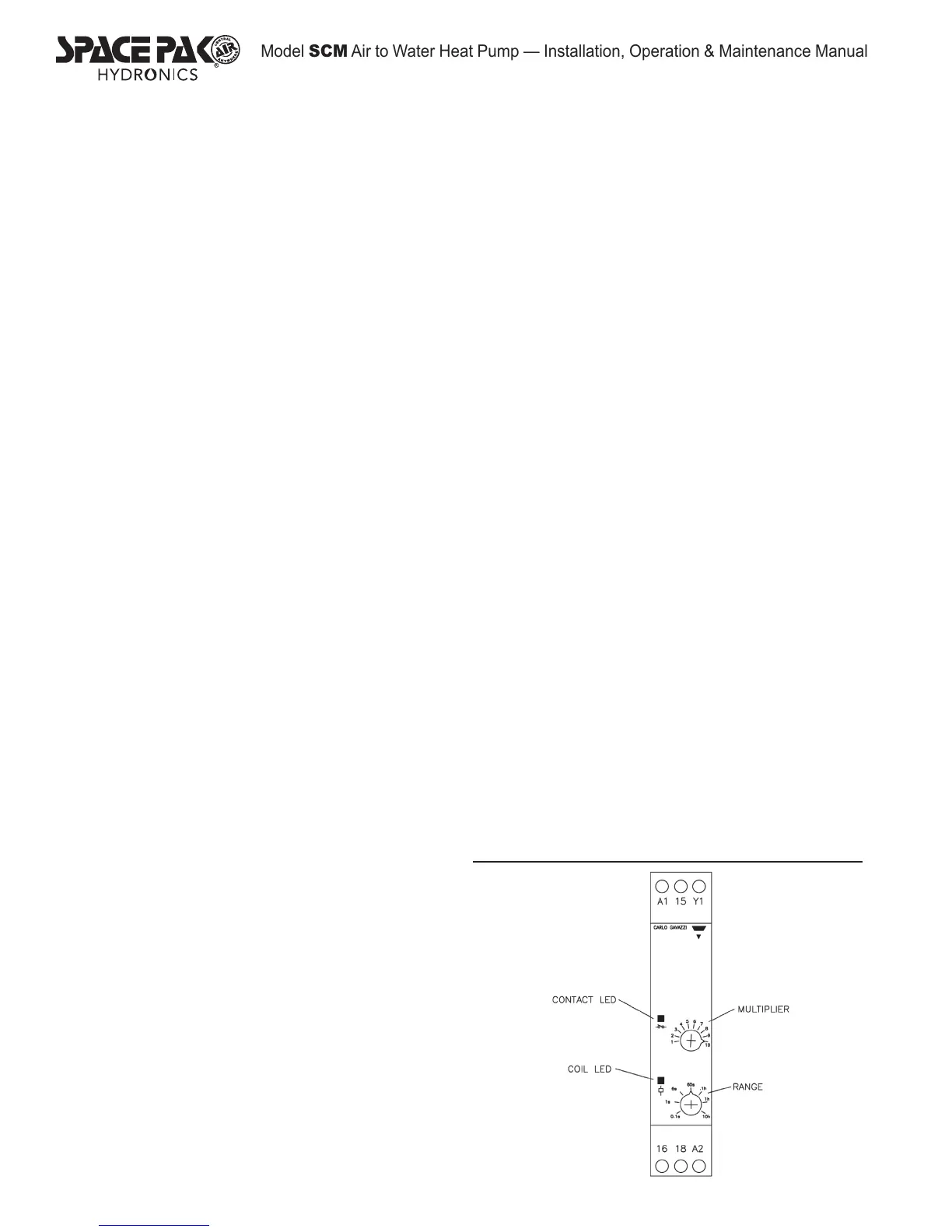

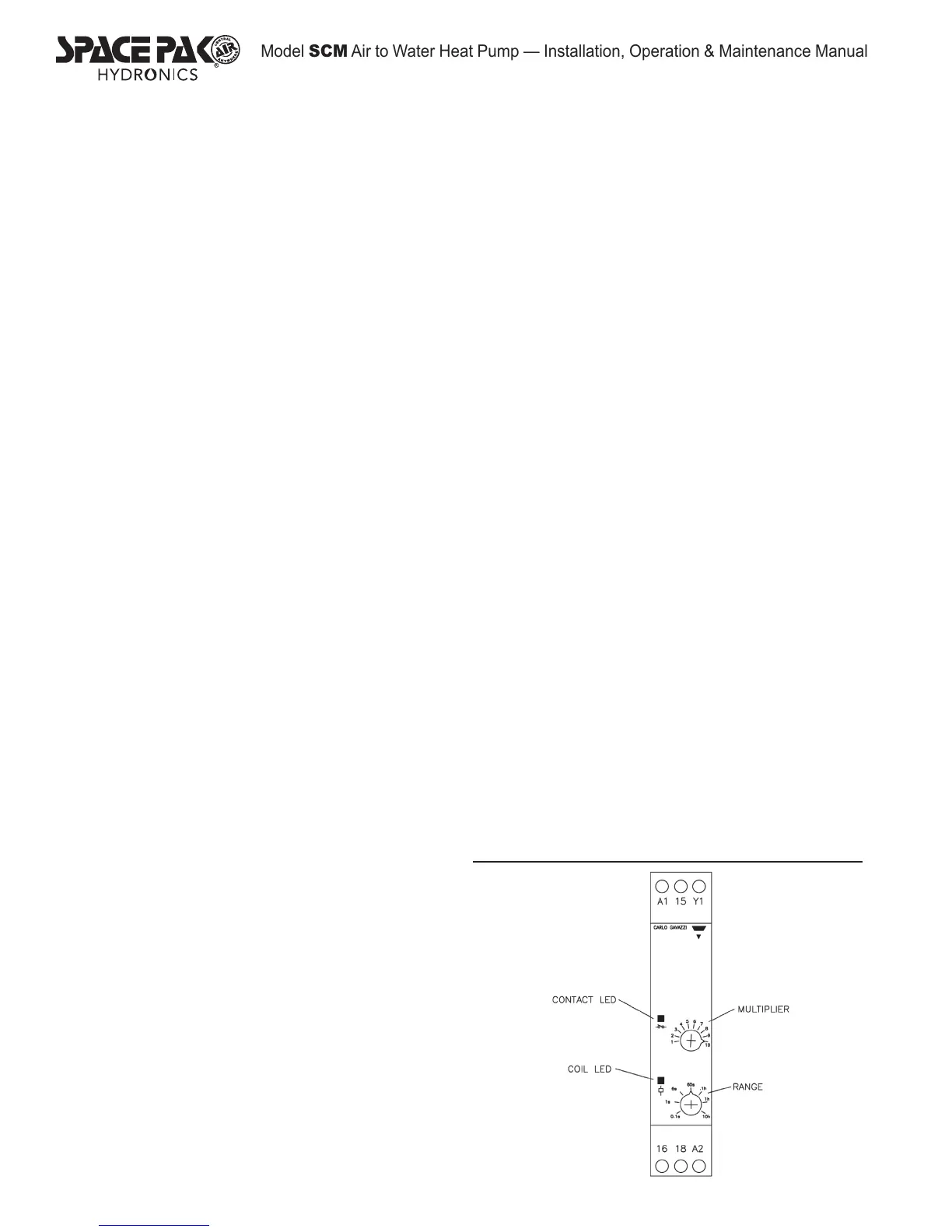

Time Delay Relay

In all instances, the heaters receive power only after a time

interval, controlled by the TDR. See Figure 15. The TDR can be

adjusted to provide a delay from .01 second, to 100 hours. This

is accomplished by two dials on the face of the components. The

lowed dial establishes the range, in increments of 0.1 second, 1

second, 6 seconds, 60 seconds, 0.1 hour, 1 hour, and 10 hours.

The upper dial is the multiplier, and increased the range from 1 to

10 times. The factory default is 10 minutes as shown in the gure;

the range is 60 seconds, and the multiplier is 10. This may be

excessively long for most applications, and may be adjusted to a

shorter interval, especially if it is primarily used for defrost operation.

When the TDR receives a signal from the controller, the Coil

LED will begin to ash, and continue for the duration of the time

delay. Once the delay has expired, the Coil LED will change to

solid, and the Contact LED will illuminate also. When the signal

is removed from the TDR, the contact will open immediately.

Protection

The heater circuit must rst prove water ow before energizing

the heaters, and maintain a circuit through an overtemp

protection device (located within the heater element) which

opens at 201°F. Should either of these conditions fail, the heaters

will immediately de-energize.

Heater Capacity

The internal circuit and switching is sufciently robust to carry the

load of the 3kW internal heater, or the (2) 3kW heaters within the

available BT-H series buffer tanks, but it cannot power all three

heaters. Therefore, the internal heater must be disconnected

from power when connecting buffer tank heaters.

Figure 15

Loading...

Loading...