Speck Pumpen Vakuumtechnik GmbH

zertifiziert: DIN EN ISO 9001

Supplementary Operating Instructions for Explosion Protection

10

7.2 Starting up / Operation / Shutdown

Compressors for the conveying of potentially explosive gas- and vapour-mixtures may initially be put into

operation, if all assembly components corresponding to the requirements of the manufacturer of the

individual components as well as the overall requirements of the compressor manufacturer were installed

and inspected in regard to their operability in detail as well as in the system and are thus fully capable of

functioning in terms of their provision.

7.2.1 General procedural method

• If an explosion danger already exists during the installation of the compressor or if a magnet-coupled

execution is entailed in the installed liquid-ring machine, the inspection in a rotational direction may

not take place under dry conditions. That concerns both the hydraulic area and the sealing areas of

double-action slide ring gaskets.

• A potential equalization for the total system according to EN 50014:2000 section 15 and further

applicable regulations must be ensured.

• The anti-cavitation protection pipe must be installed and be operational.

• Foreign particles from ferrous material may not get under the coupling protection. Danger of spark

formation.

• The operation with closed shut-off equipment in the suction- and pressure-pipes is not permissible.

7.2.2 Sufficient supply with operating liquid

After inspection for the absence of malfunction, the clearance to start by LS- 01 or LS- 02 (comp. Fig. 7.1)

and the start of the liquid-ring compressor, the appropriate time lag is necessary for the activation of the

flow-rate switch FS- 04. The time lag depends on the size of the compressor, the intake pressure and the

viscosity of the operating liquid. It is between 5 s and 90 s.

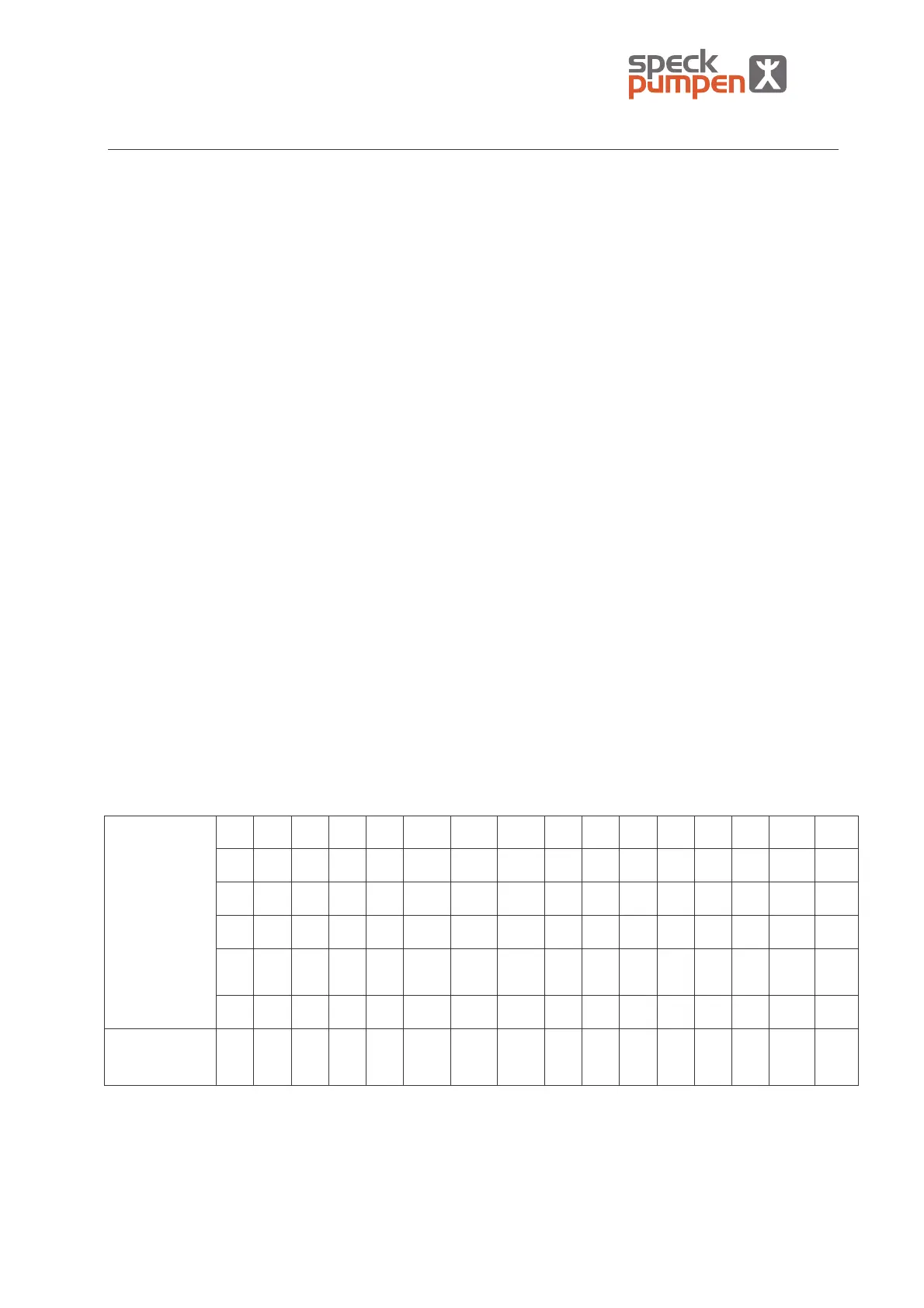

The volumetric currents of the operating liquid depend on the size of the compressor, the operating liquid

used and the operating parameters. The switching points of the switch FS- 04 are therefore to be

adjusted (see data sheet). The following table shows the switching ranges for water as the operating

liquid with a differential of at least 600 mbar between suction- and operating liquid-pressure.

VH

20

VH

40

VH

60

VH

110

VH

140

VH

180

VH

300

VH

350

VH

400

VH

500

VH

600

VH

800

VH

1200

VH

1600

VU

20

VU

40

VU 80

VU

140

VU

220

VU

300

VU

450

VU

500

VU

600

VU

800

VU

1200

VU

1600

VZ

30

VZ

50

VZ

110

VZ

140

VZ

180

VN 95

VN

125

VN

180

V

6

V/V

G

30

V/V

G

55

V/V

G95

V/VG

130

V/VG

155

V/VG

255

V

330

V

430

Compressor-size

VI 2 VI

8/15

VI

30

VI

55

Switching point

FS- 04

[l/min]

0,5

to

1,0

1,0

to

2,0

3,5

to

5,0

3,5

to

5,0

6,5

to

10

9,0

to

13,5

9,0

to

13,5

9,0

to

13,5

10

to

18

10

to

18

10

to

18

12

to

22

12

to

22

20

to

60

20 to

60

20 to

60

Tab. 7.1 Amounts of operating liquid in the liquid-ring compressors

Loading...

Loading...