Speck Pumpen Vakuumtechnik GmbH

zertifiziert: DIN EN ISO 9001

Supplementary Operating Instructions for Explosion Protection

33

8 Maintenance

Regular maintenance is to be performed with use in an operation prone to explosion. Defective parts and

components are to be replaced. Only replacement parts approved by the pump manufacturers are to be

used.

The operator alone is responsible for the performance of monitoring procedures, maintenance

and inspections. The procedures used are to be documented in written form.

So that with easily inflammable gases no potentially explosive gas-air mixtures can arise, the compressor

must be sufficiently flushed with inert gas before the opening of the compressor as well as before the

reconnection after the opening of the compressor.

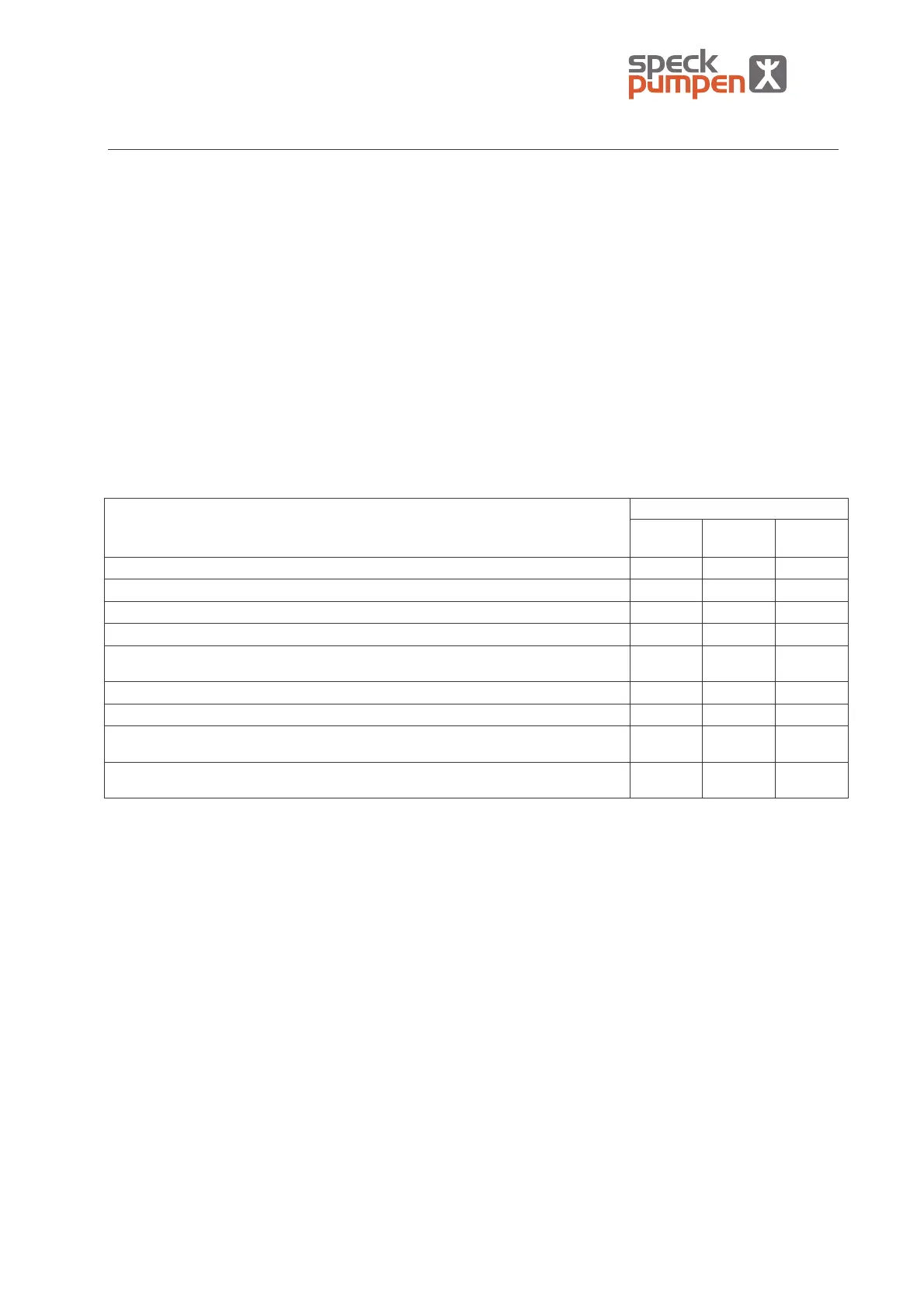

Checklist for maintenance work

Intervals

Maintenance procedures

every

14 days

every

2000 h

every

8000 h

Acoustic test for absence of cavitation

X

Acoustic check of the bearings (compressor and motor)

X

Visual test for absence of leakage

X

Visual run-out test of the coupling

X

Relubrication of the anti-friction bearings VU 300/450; VU/VH 500/600 with 8g

grease

X

Relubrication of the anti-friction bearings VU/VH 800 – 1600 with 15g grease

X

Replacement of all bearings and gaskets (dynamic and static)

X

Disassembly of the compressor and test of all parts for mechanical, corrosive and

cavitation damages.

X

Functional test of the control technology. (Equipment-specific operating instructions

are to be observed.)

X

Loading...

Loading...