Installation of Bearing Display Module BDM

4

Measuring

circuit board

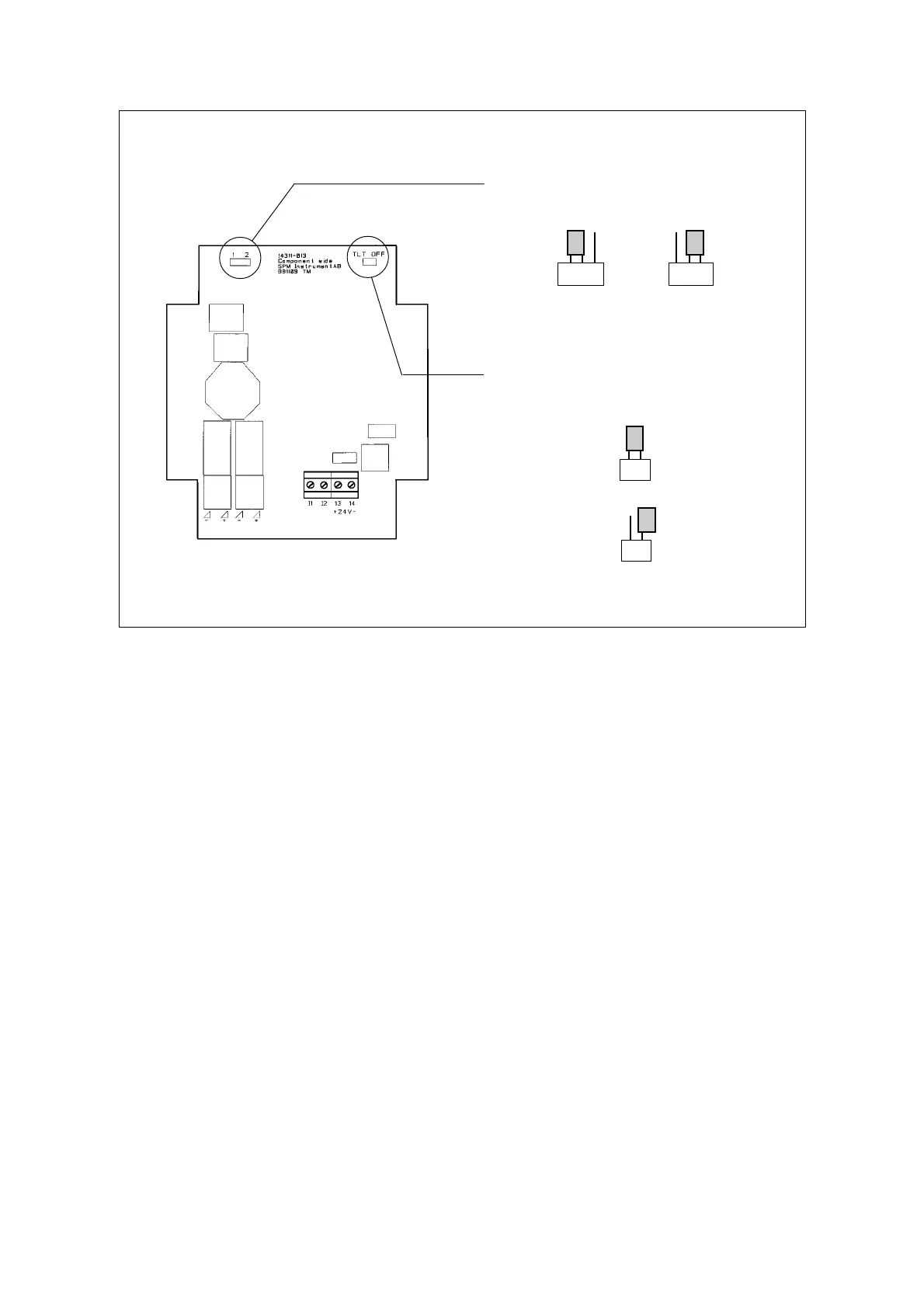

BDM modules contain two circuit boards, the bearing measuring circuit board (lower) and the display

circuit board (upper) for 4 – 20 mA analog signals. The analog output(s) on the measuring board are

factory connected to the display board.

All electric connections are made to the upper display circuit board. The lower board has two jumpers,

one is used to select the measuring range and one to select TLT OFF (this jumper is factory mounted on

one of the contact pins).

Measuring range setting

The jumper socket marked 1 2 in the upper left corner on the circuit board is used to set the measuring

range in unnormalized shock values:

1. 0 – 80 dBsv 2. 20 – 100 dBsv

One of these ranges must be selected and have effect on both channels. The factory setting is 0 - 80 dBsv.

The range can be changed at any time. Note that the display range program or the PLC must be changed

accordingly.

TLT OFF (test)

In case of transducer line fault (open or short circuit), the analog signal goes down to <1 mA. To avoid

problems with e.g. a PLC, one can move the jumper to both contact pins at ”TLT OFF” on the circuit

board. This will eliminate the transducer line test and keeps the channel output at min. 4 mA in case of

fault.

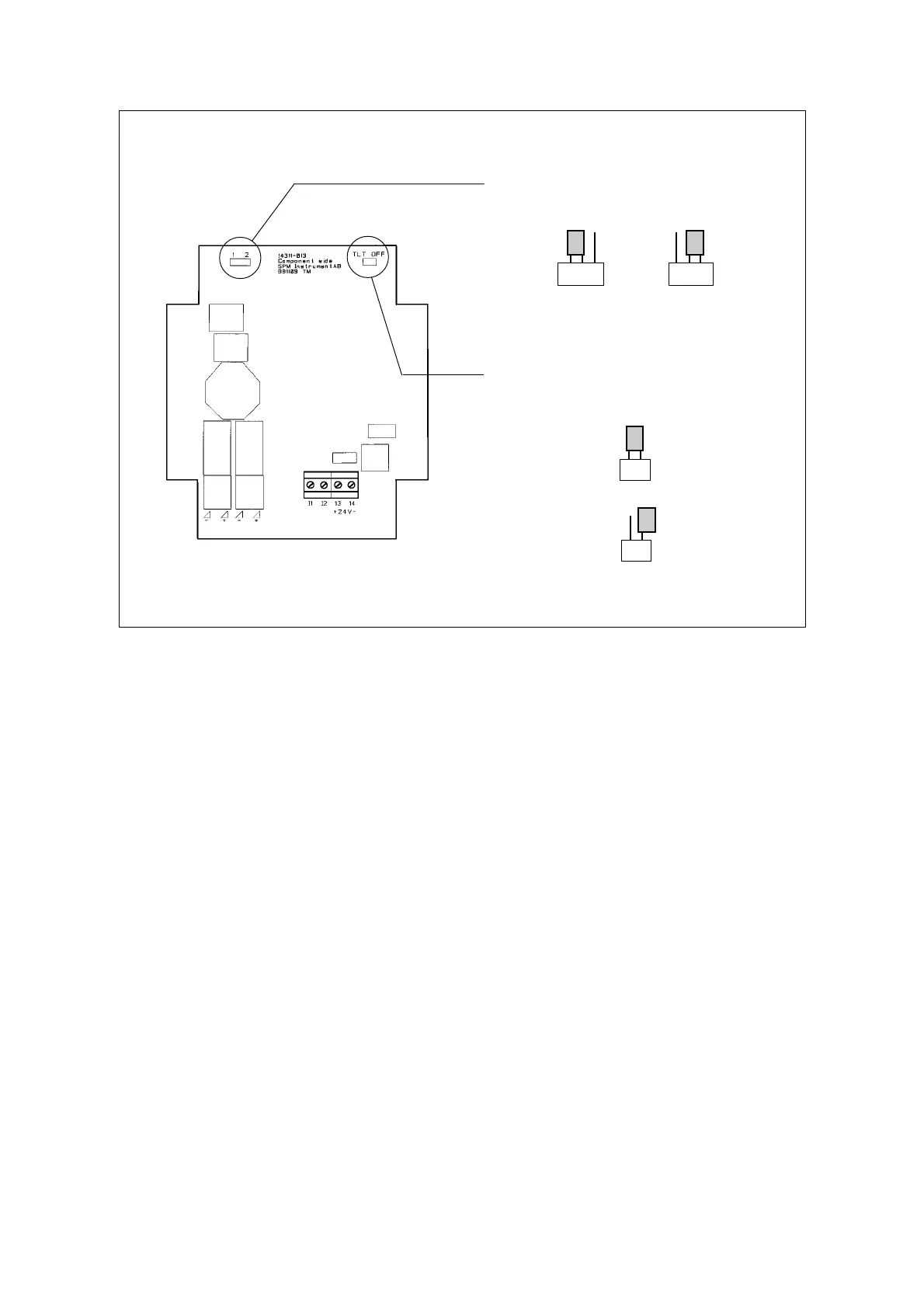

0 – 80 dBsv 20 – 100 dBsv

TLT OFF (test)

12

12

A jumper can be set at TLT OFF for test

(min. 4 mA in case of TLT fault)

TLT (normal)

Jumper for setting of measuring range

Loading...

Loading...