3

Installation of Bearing Display Module BDM

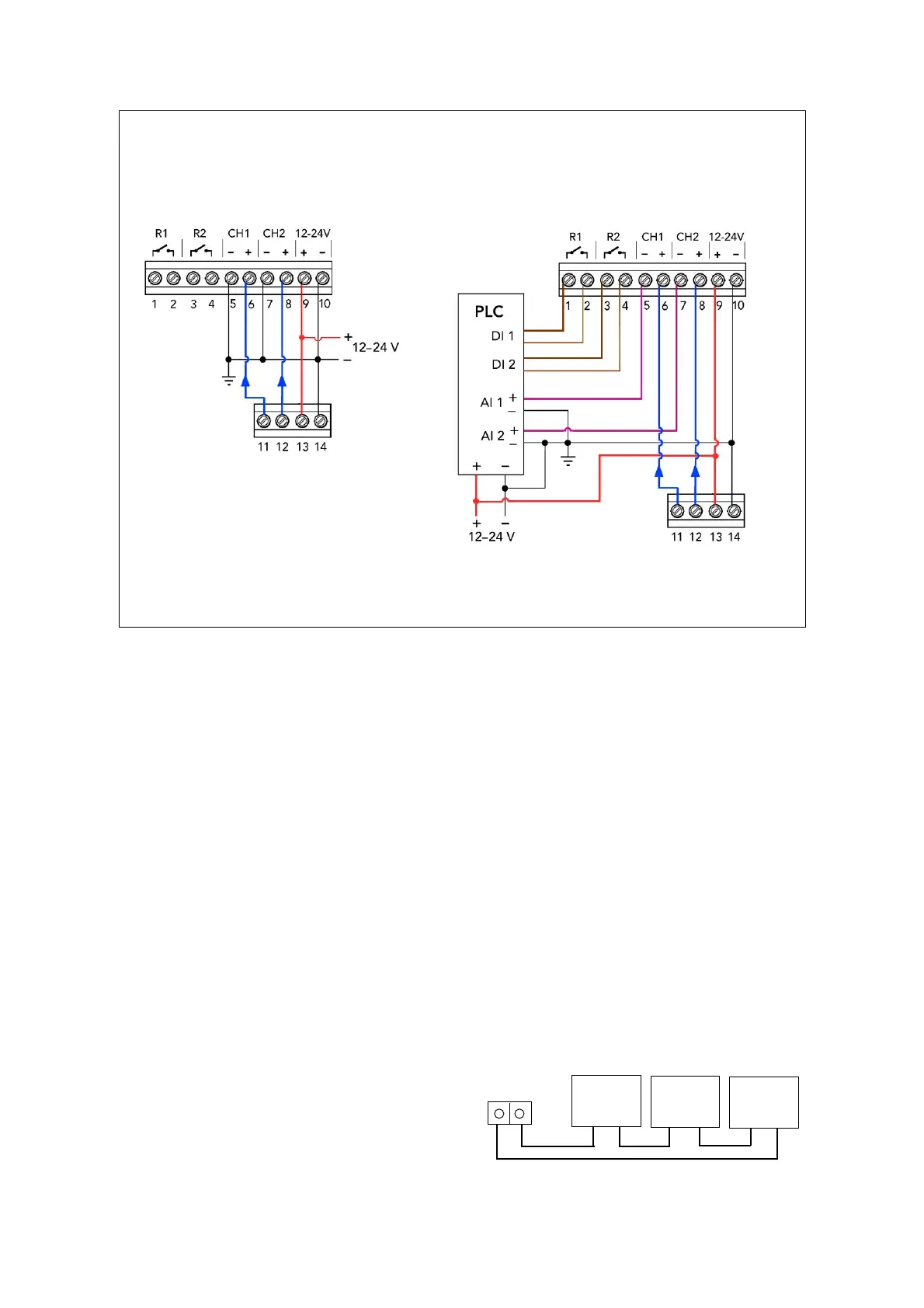

The analog signals 4 - 20 mA can also be used in

the AMS unit for on-line condition monitoring in

connection with the SPM Condmaster

®

Pro soft-

ware.

Note that the max. total loop resistance of a 4-

20 mA circuit depends on the signal source. As a

rule, loop resistance should not exceed 400 Ω in

a CMM system.

Loop resistance R = 47 + 47 + 75 = 169 Ω

+ cable resistance. Maximum 400 Ω

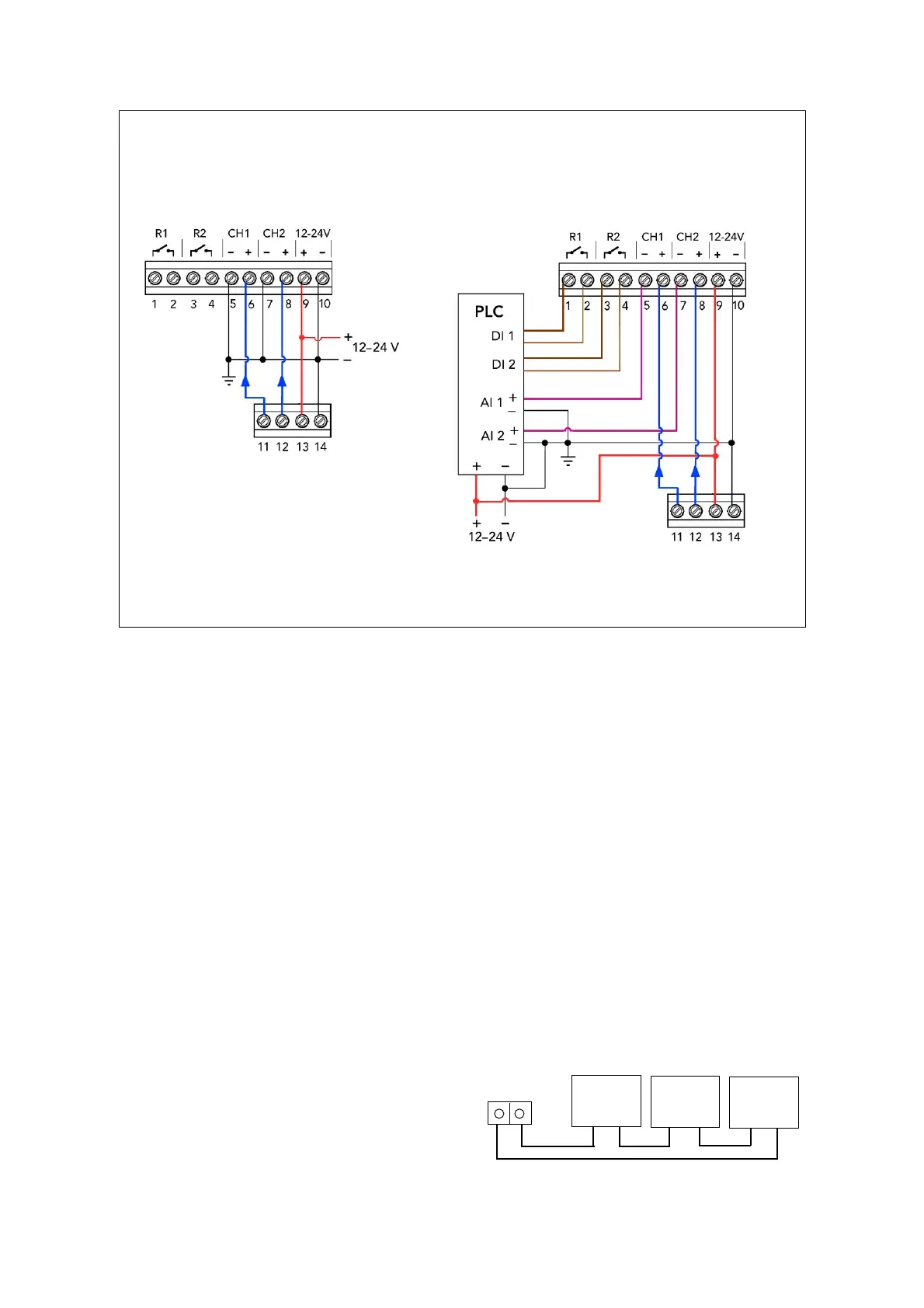

Electrical installation

When used as a stand-alone display unit, the module is connected to a 12 - 24 V DC power source with

earth reference. All electric connections are made to the upper circuit board. The jumpers connecting

the analog channels to earth are factory mounted and can be removed when connecting to a PLC.

BDM modules are delivered with jumpers that connect the 4 - 20 mA output of the lower measuring

circuit to the upper display circuit.

When connected to a PLC, the display module can get its power supply from it. The jumpers from the

analog channels are removed. The analog channels are connected to the PLC's AI (analog in) unit, the

relays to the DI (digital in) unit.

Please note: The return line from the current loop are connected to the negative pole on the power

supply.

Mechanical installation

The module is wall mounted, with 4 screws through the back of the casing. The screw diameter is 4 mm, the

spacing is 109 x 94 mm. The module housing has a transparent lid fixed to the box by four screws and has

to be opened for installation and programming. The maximum vibration exposure is 5 mm/s RMS. The

temperature range is 0 to 55 °C (32 - 130 °F). The incoming signal/power cables must have a diameter of 5.5

to 10 mm to maintain IP65.

Analog

signal

– +

PLC

75 Ω

+ –

AMS

47 Ω

+ –

BDM

47 Ω

+ –

4–20 mA

BDM connected to PLC

measuring circuit board

(lower)

BDM

measuring circuit board

(lower)

Loading...

Loading...