8

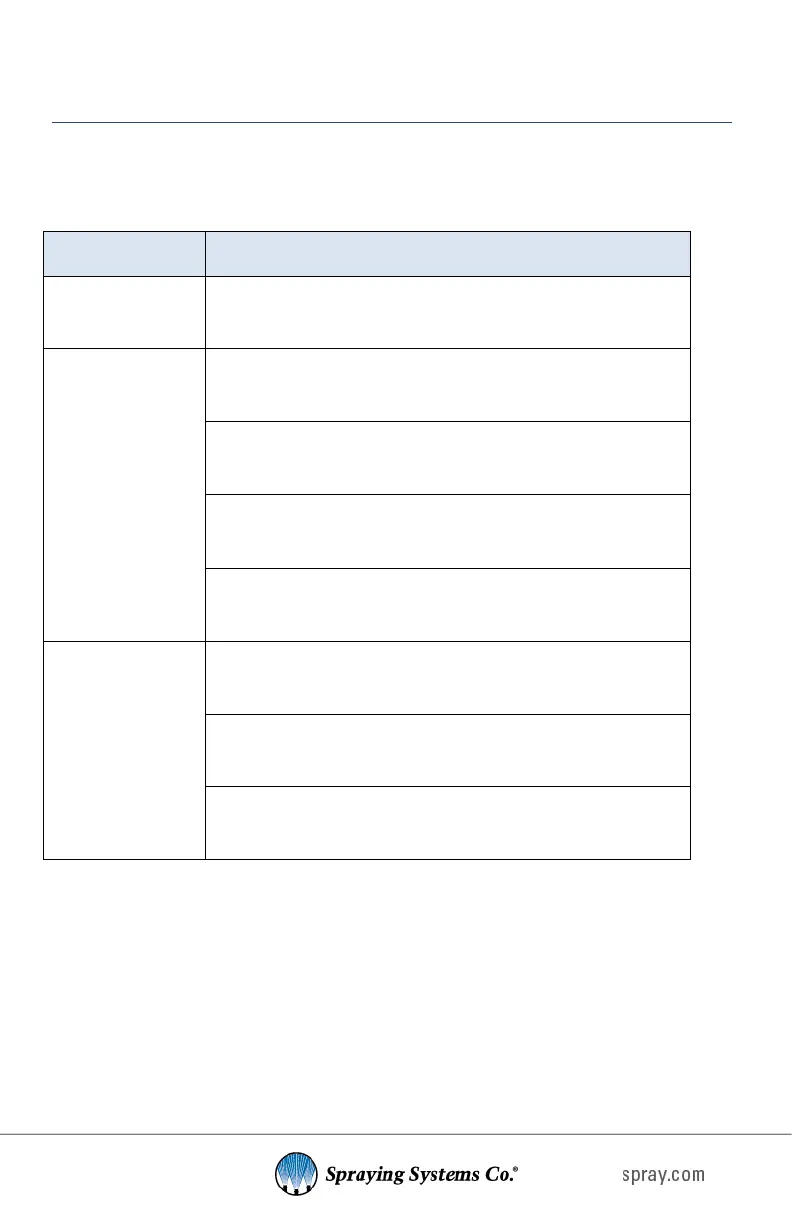

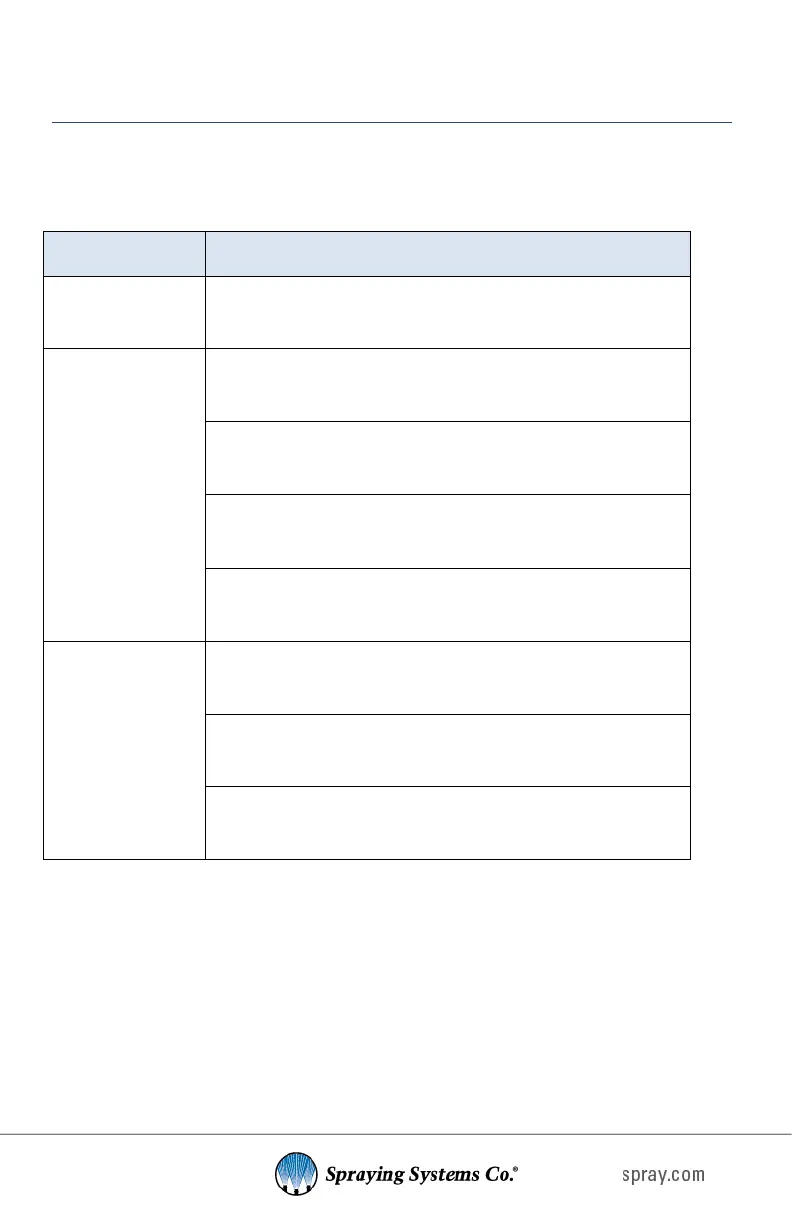

TROUBLESHOOTING

Certain conditions could occur to cause a malfunction or unsatisfactory operation

of the spray nozzle. These conditions are addressed in the table below:

Problem Possible Cause

Poor spray

performance

Clogged spray tip. Remove spray tip and clean orifice or

replace tip.

No fluid flow

Clogged spray tip. Remove spray tip and clean orifice or

replace tip.

Debris in fluid passages. Disassemble nozzle and clean fluid

passages.

Plunger not operational. Check coil for nominal resistance of

67 Ohms. If open or shorted, replace nozzle.

Check fuse. If open, replace with 3/10 amp fast acting fuse.

No shut-off

Debris in fluid passages. Disassemble nozzle and clean fluid

passages.

Broken spring. Disassemble nozzle and replace spring.

Worn seat. Disassemble nozzle and replace with

AB10000AUH-03-Z1-KIT spare parts kit.

Loading...

Loading...