5

8

1

5C 5D

8

7

2

6

1

5A

10A

9A

3A

3B

9B

10B

5B

11

INLET

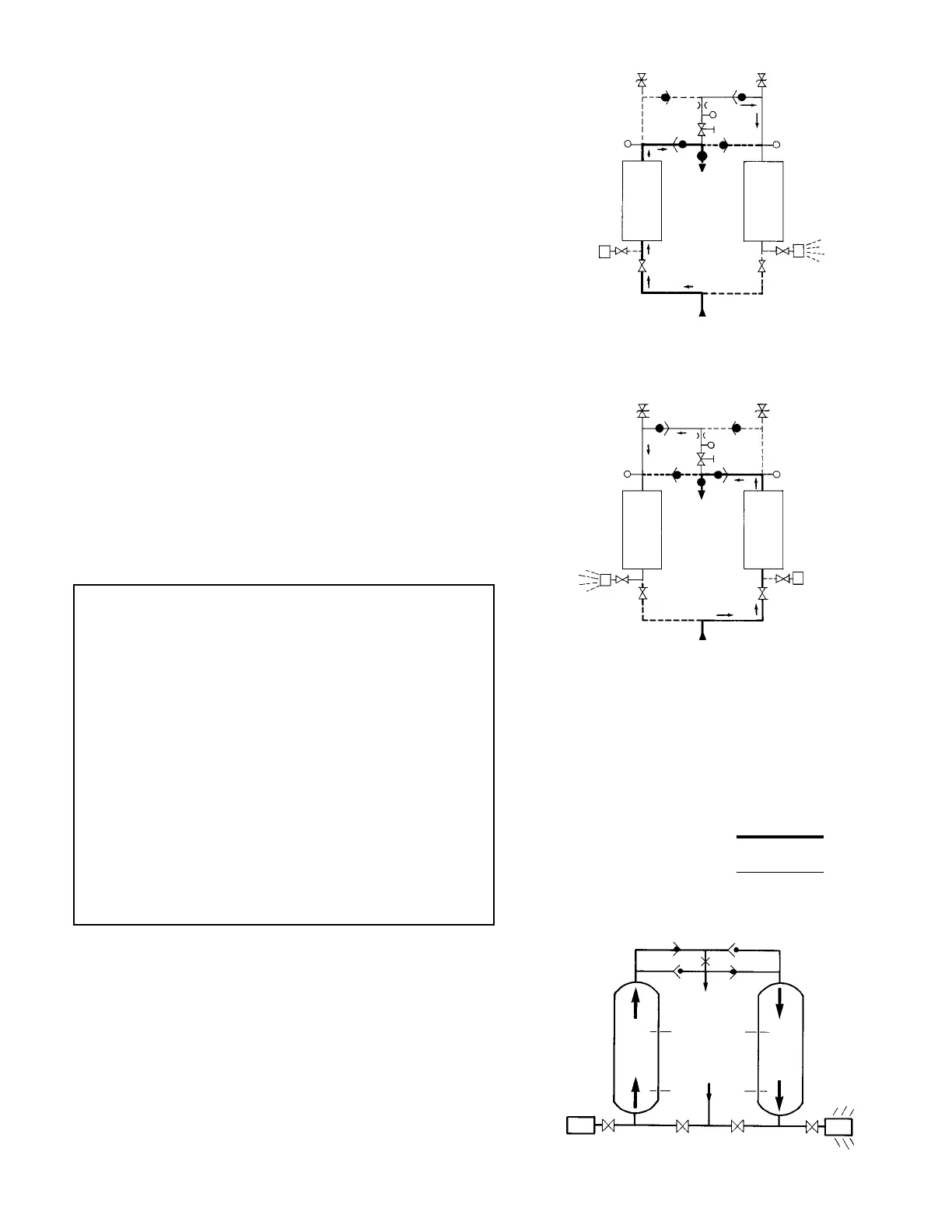

FIGURE 1A

88

5C

5D

7

2

6

1

1

5A

5B

11

10A

9A

3A

10B

9B

3B

INLET

LEGEND

Process Stream

Purge Stream

TOWER 4A DRYING: TOWER 4B REGENERATING

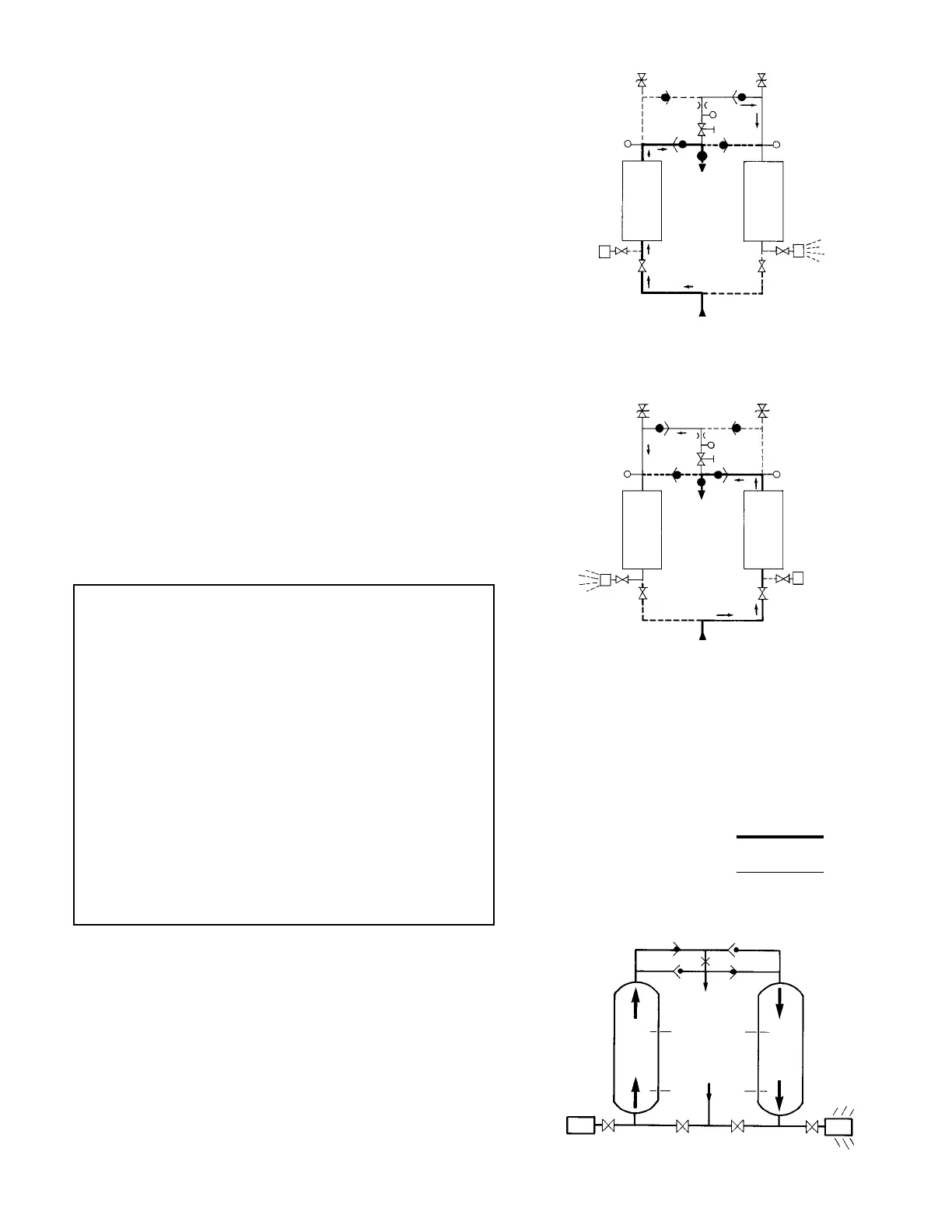

FIGURE 1C

7. Purge Orifice

8. Pressure Relief Valves

9. Purge / Repressurization Valves

10. Purge Mufflers

11. Moisture Indicator

1. Pressure Gauges

2. Purge Pressure Gauge

3. Inlet Switching Valves

4. Desiccant Drying Towers

5. Check Valves

6. Adjustable Purge Rate Valve

FIGURE 1B

TOWER 4B DRYING: TOWER 4A REGENERATING

1.2 Description of Operation

1.2.1 Dryer

(Refer to Figure 1A.)

Compressed air flows through inlet switching valve (3A) to tower

(4A) where the air is dried. After the air is dried it flows through check

valve (5A) and then to the dryer outlet.

A portion of the dry air, the purge stream, branches off from the

main air stream prior to the outlet. The purge stream flow rate is controlled

by the adjustable purge rate valve (6) and the purge orifice (7).

The purge flow, which has been throttled to near atmospheric

pressure, is directed through check valve (5D) to tower (4B). As the purge

flow passes over the desiccant in tower (4B), it removes the water vapor

which was deposited there while the tower was on-line drying. The purge

air then passes through purge and repressurization valve (9B) and purge

muffler (10B) to the atmosphere.

After regeneration, purge and repressurization valve (9B) closes

allowing tower (4B) to repressurize slowly. Adequate repressurization time

is allowed so that tower 4B is fully repressurized before switchover. After a

controlled time period, air inlet switching valve (3B) opens and inlet

switching valve (3A) closes, purge and repressurization valve (9A) then

opens.

(Refer to Figure 1B.)

Tower (4B) is now drying the main air

stream while tower (4A) is being regenerated by the purge air stream. The

operation of the inlet switching and purge and repressurization valves is

sequenced by the control system located in the electrical box.

1.2.2 Optional Automatic Purge Saving System (Refer to Figure 1C)

Assume Tower A is on-line drying the air while tower B has just

gone off-line to be regenerated. At the beginning of tower B’s regenera-

tion cycle a temperature measurement is made at position B1. After the

tower has been regenerated, another measurement is made at B1. The

drop in temperature sensed during regeneration is an indirect measure

of the water vapor content of the inlet air. The Purge Saving System’s

microprocessor then uses this information to calculate an allowable

temperature rise in the bed during the drying cycle.

When tower B goes back on-line, a temperature probe at

position B2 measures the initial bed temperature at this point and then

monitors the bed until the calculated temperature rise occurs. The

temperature rise occurs as heat of adsorption is released during the

drying process. The time for the temperature rise to occur depends on

flow rate. At 100% flow the temperature rise takes five minutes, at 50%

flow it takes 10 minutes.

When the calculated temperature rise is reached, the towers

switch with tower A now drying and tower B being regenerated. Tower B

regenerates for 3.9 minutes, repressurizes, and remains idle until it is

called upon for the next drying cycle.

TOWER

4B

TOWER

4A

OUTLET

OUTLET

TOWER

4A

TOWER

4B

OUTLET

INLET

A2

B2

TOWER

A

TOWER

B

B1

A1

Loading...

Loading...