8

UK

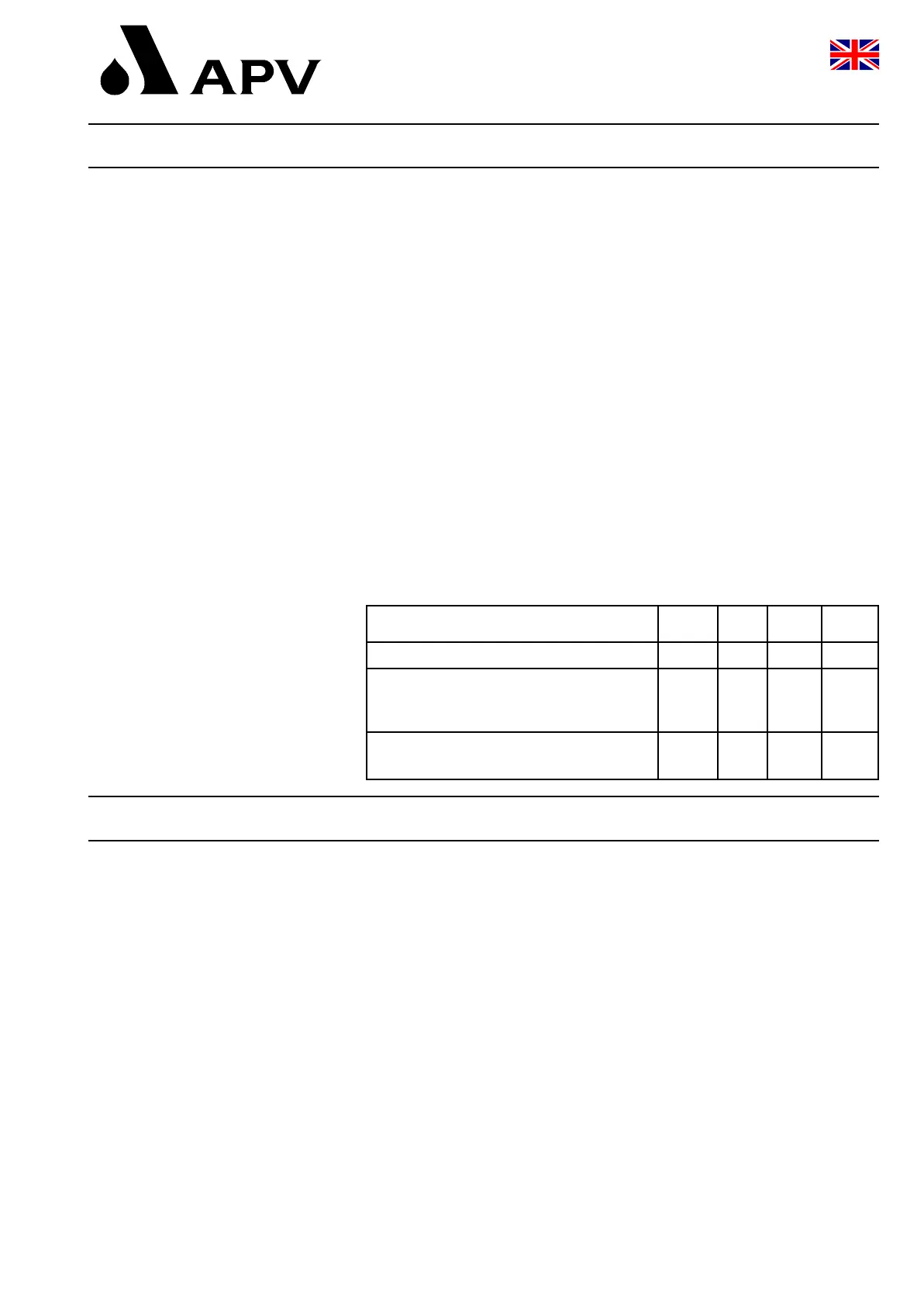

DN 50 80 100

max. tightening torque in Nm ( M ) 22 40 65

operating leakage at about

5 bar in L ( Qs) 1,4 4,0 4,2

( opening and closing operation )

pneumatic air consumption

at 6 bar in NL ( V ) 1,8 5,5 5,5

9. Technical Data

- max. line pressure : 10 bar

- max. operating temperature : 135

o

C EPDM, HNBR

*FPM, *VMQ

- short-term load : 140

o

C EPDM, HNBR

*FPM, *VMQ

* no steam

- throughput cleaning

at 3 bar admission pressure : about 5 - 10 l/min.

-actuator

max. control pressure : 10 bar

min. control pressure : 6 bar

turning angle : 90

o

- leakage connection : G1/8

- cleaning connection (for hose ) : 8 x 1mm

- air connection (for hose) : 6 x 1mm

(Use dry and clean air, only.)

10. Maintenance

- Dismantling and installation of seals according to service

instructions.

- Assembly and adjustment of turning actuator according to

service instructions.

- Slightly grease all seals.

Recommendation:

APV food-grade-grease for EPDM and FPM

(750 g/tin - ref.-No. 000 70-01-019/93)

(60 g/tube - ref.-No. 000 70-01-018/93)

or

APV food-grade-grease for VMQ and Perbunan

(600 g/tin - ref.-No. 000 70-01-017/93)

(60 g/tube - ref.-No. 000 70-01-016/93)

! Do not use grease containing mineral oil with EPDM seals !

! Do not use Silicone-based grease with VMQ seals !

Double - Seat Ball Valve DELTA DKRT 2

Tank Outlet Valve

Operating Manual : Rev. 4

Loading...

Loading...