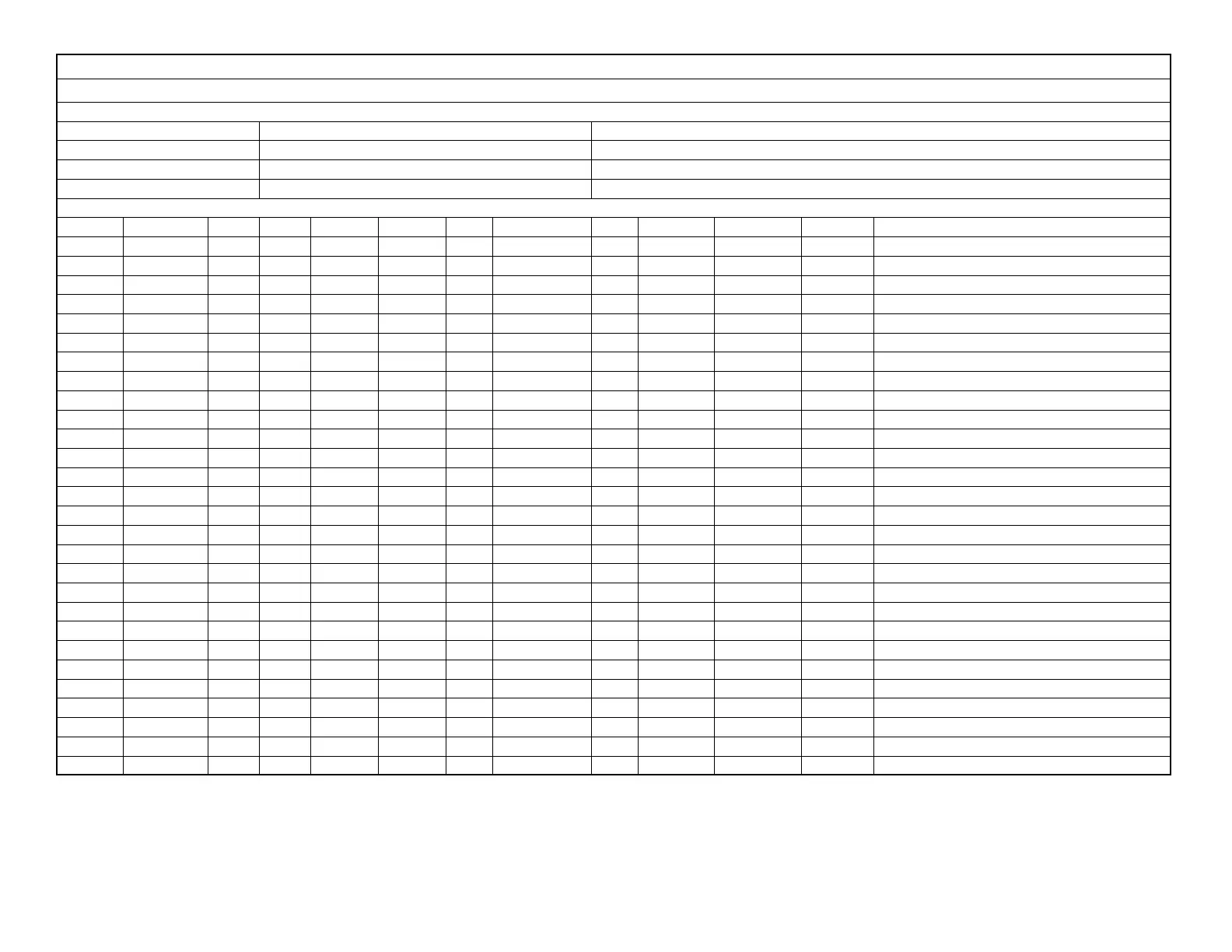

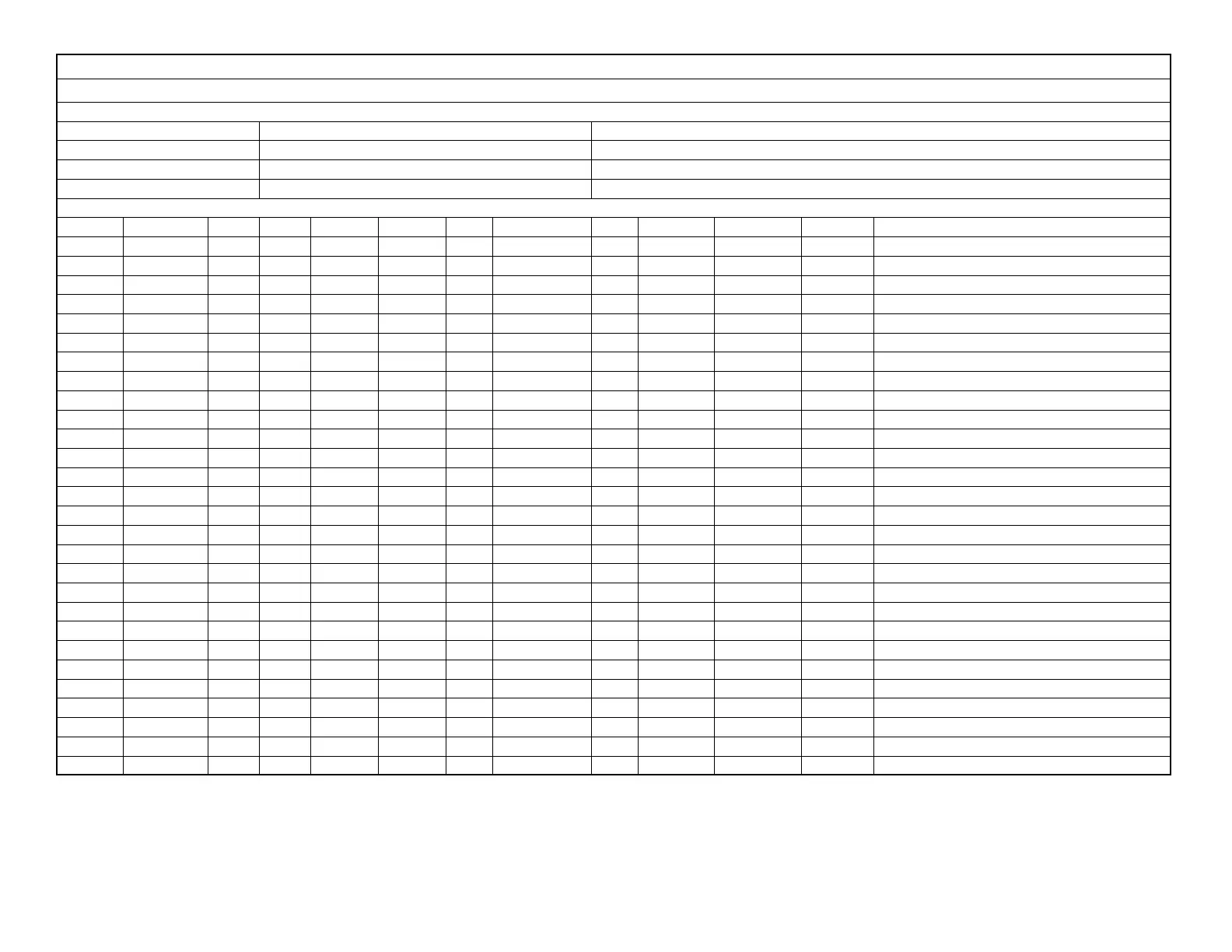

Step No. Step Type Gas 1 Gas 2 Vacuum Exhaust Heat HH:MM:SS Rate PID Set Guar Soak End Step Notes

1 ramp time 0:00:01 24 1 no Initialize start from room temperature

2 soak on 0:00:40 1 no Evacuate the chamber

3 soak on 0:00:05 1 no Backfill to 10 psig

4 soak on on 0:00:30 1 no Purge with nitrogen

5 soak on 0:01:00 1 no Initial vacuum

6 ramp time on on 0:01:30 240 4 no Ramp to 240 C under vacuum

7 soak on on 0:02:00 240 2 no Soak at 240 C under vacuum

8 soak on on 0:00:10 2 no backfill to 4 psig

9 ramp time on 0:01:00 325 4 no Ramp to 325 C with 4 psig

10 soak on 0:02:00 325 2 no Soak at 325 C with 4 psig

11 ramp time 0:00:01 24 1 no Initialize controller to room temperature

12 soak 0:04:00 1 no Allow solder to cool below melting point

13 soak on on 0:02:00 1 no Assist cooling with gas1 and exhaust

14 END ALL OFF

17

18

19

20

21

22

23 PID settings Pband Rate Reset

24 PID 1 20 3 7

25 PID 2 25 2 14

26 PID 3 15 3 14

27 PID 4 7 3 7

28 PID5 60 3 27

29

30

SST International Model 1200

Sample Profile

Profile Name:

Lid AuSn 30 psig

Gas 1 Pressure Set: Gas 2 Pressure Set:

30 psig

Gas 2 Flow Meter Set:

20 SCFH

Date Programmed:

80 SCFH

Gas 1 Flow Meter Set:

Loading...

Loading...