During normal operation, this pump is immersed in water. Also, during rainstorms, water may be present in the surrounding

area of the pump. Caution must be used to prevent bodily injury when working near the pump. Electrical power should be

disconnected prior to touching, servicing, or repairing the pump.

Do not run the pump in a dry basin. If the pump is run in a dry basin, the surface temperature of the pump

will rise to a high level. This high temperature could cause skin burns if the pump is touched and will

cause serious damage to your pump. Do not install in locations classified as hazardous in accordance

with the National Electrical Code, ANSI/NFPA 70. Do not remove cord and strain relief. Do no connect

conduit to pump.

Caution

For best performance of check valves, when handling solids install in a horizontal position or at an angle of no more than

45°. Do not install check valve in a vertical position as solids may settle in valve and prevent opening on start-up. A gate

valve should follow the check valve to allow periodic cleaning of the check valve or removal of the pump. The remainder

of the discharge line should be as short as possible with a minimum of turns to minimize friction head loss. Sewage and

effluent applications will require a separate sump vent. A connection is provided on top of the sump or cover which must

be piped to the existing building vent or extended outside with its own standpipe.

When working on pump or switch, always unplug pump power cord in addition to removing or shutting off circuit

breaker before working on pump.

Wiring

Check local electrical and building codes before installation. The installation must be in accordance with their

regulations as well as the most recent National Electrical Code (NEC).

Pump should be connected or wired to its own circuit with no other outlets or equipment in the circuit line. Fuses and

circuit breaker should be of ample capacity in the electrical circuit.

Maintenance

If the pump does not operate properly or trouble shooting doesn’t work, consult your pump dealer or take pump to a

Stancor authorized service center.

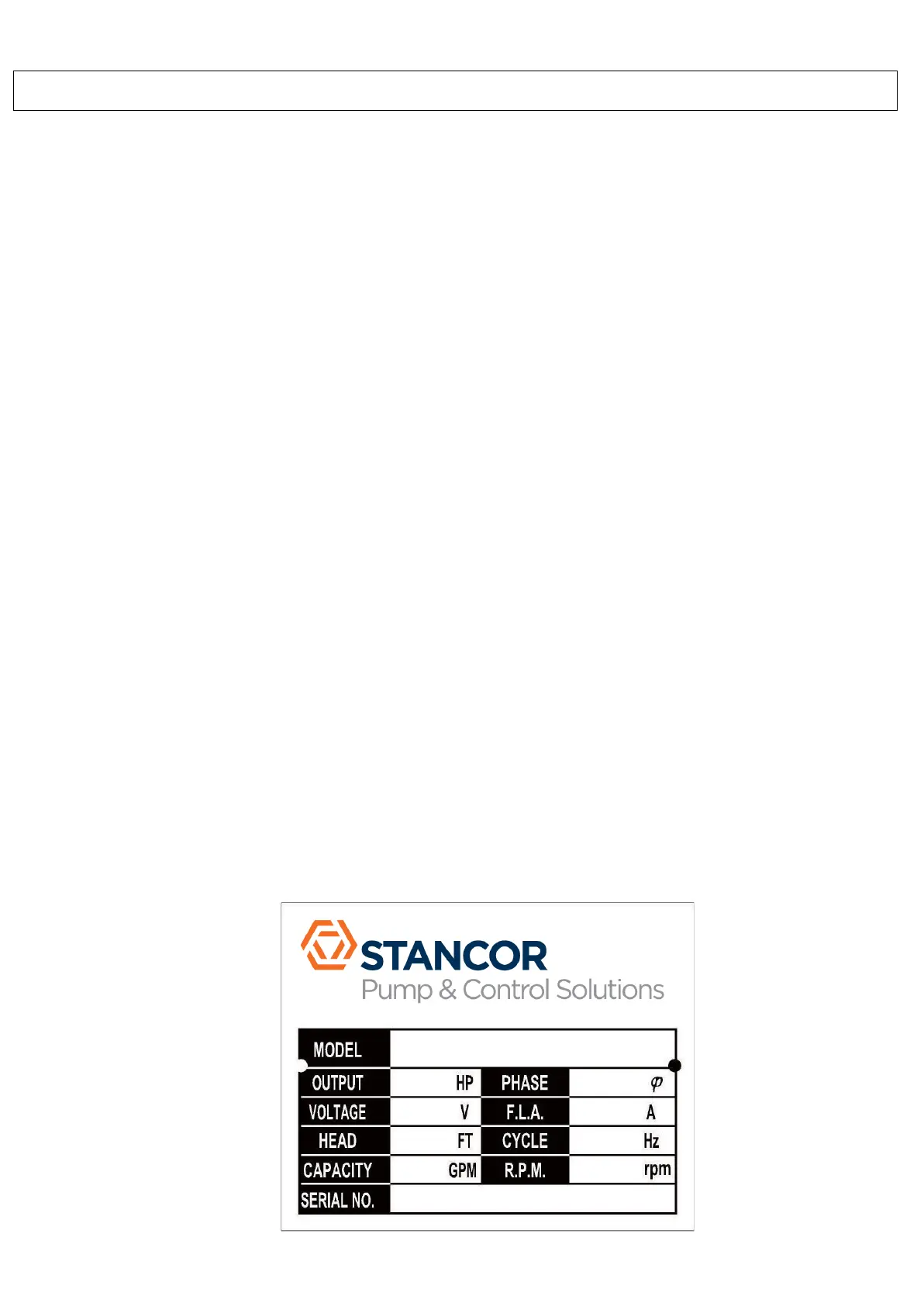

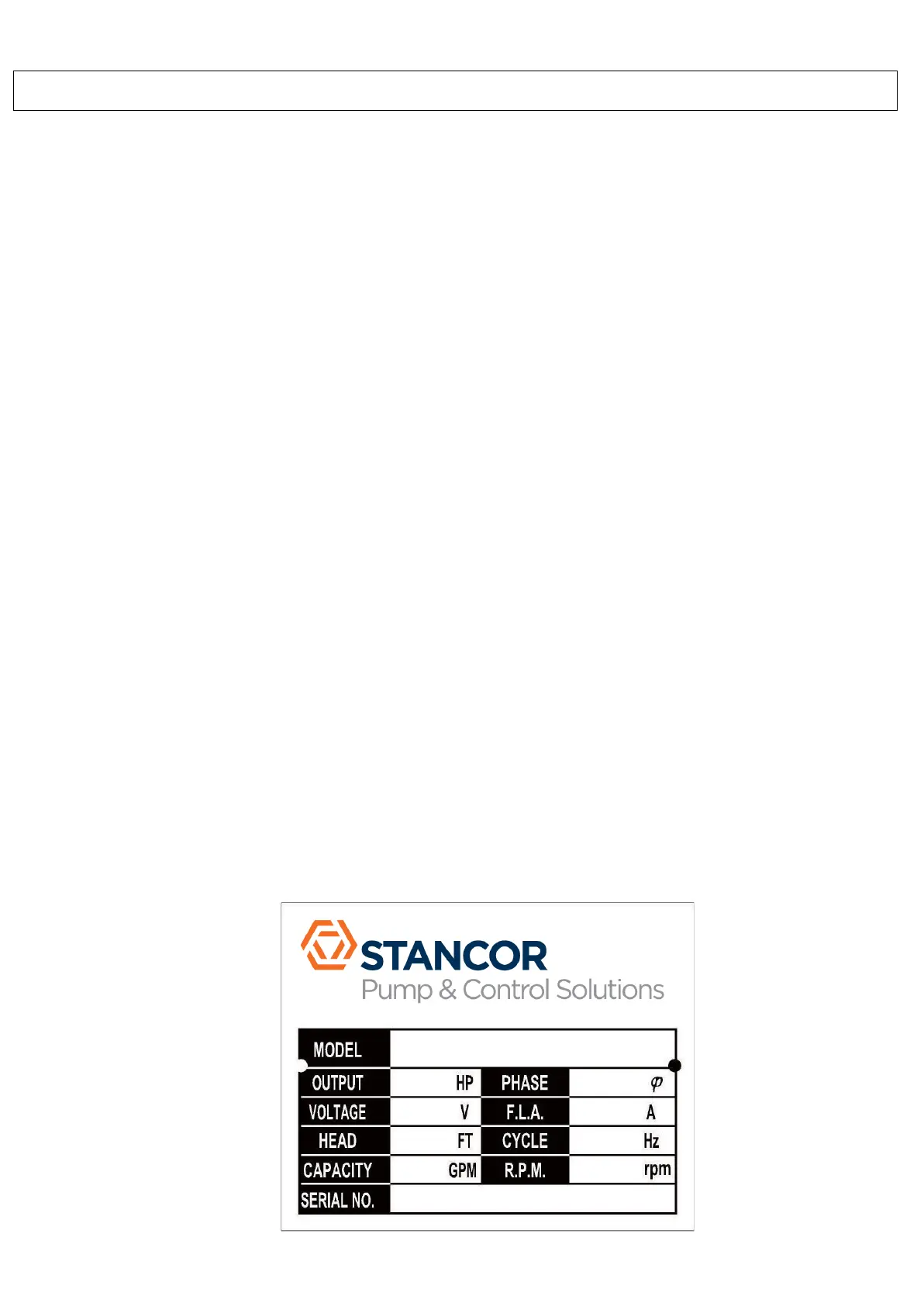

Nameplate format

DO NOT USE TO PUMP FLAMMABLE OR EXPLOSIVE FLUIDS SUCH AS GASOLINE, FUEL OIL, KEROSENE, ETC.

FAILURE TO FOLLOW THIS WARNING CAN RESULT IN PERSONAL INJURY, DEATH AND/OR PROPERTY DAMAGE.

Loading...

Loading...