English

7

(original instructions)

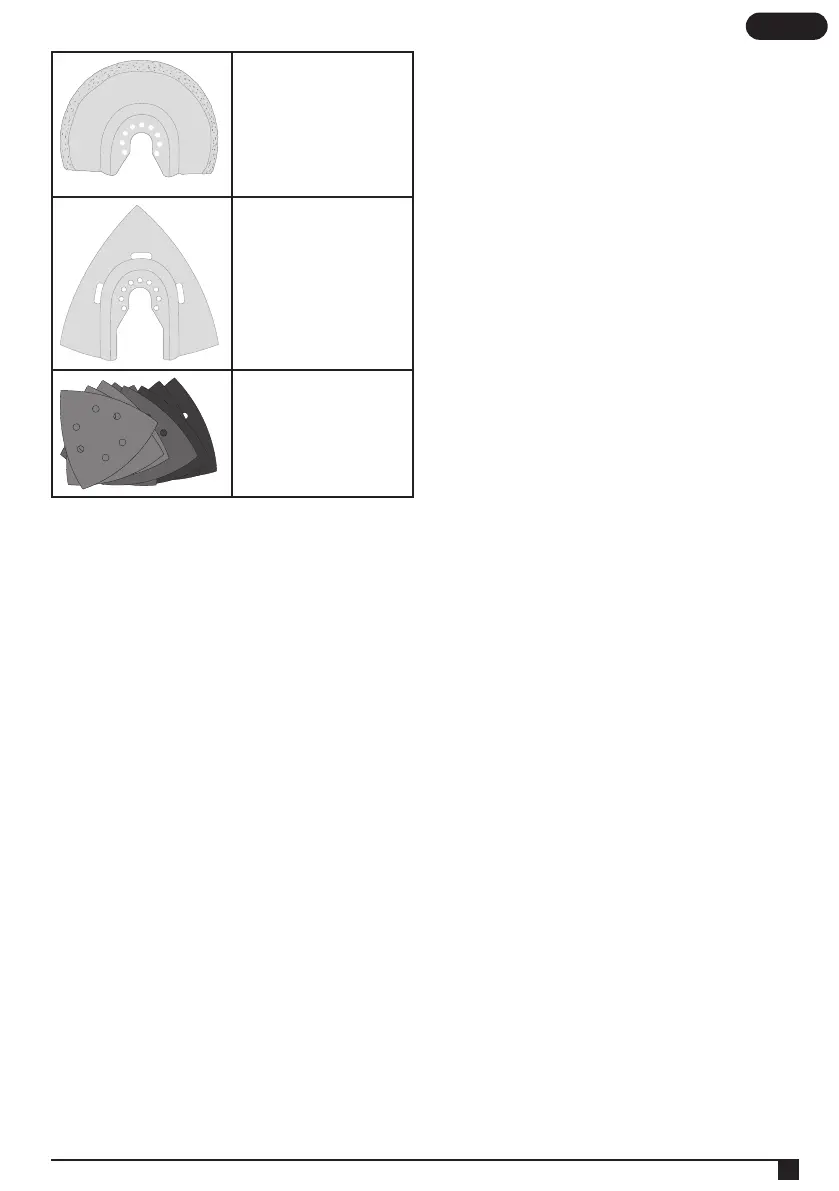

Carbide grout removal blade.

(Part number - STA26125-XJ)

Carbide coated surface ideal for

clearing grout and tile adhesive from

at surfaces and for fast stock

removal of wood, chipboard

and breglass.

Carbide rasp.

(Part number - STA26130-XJ)

Carbide coated surface ideal for grout

removal and for fast stock removal of

plastics, chipboard and breglass.

Sanding Sheets.

(Part number - STA32348-XJ)

Various grades for sanding of wood,

painted and varnished surfaces.

Assembly

Fitting and removing the accessories (g. A–G)

@

Warning! Before tting an accessory, disconnect the

tool from the mains supply.

Fitting a STANLEY FATMAX accessory (g. A–C)

● Hold the tool and squeeze the accessory clamping

lever (3).

● Slide the accessory (9) between the shaft and the

accessory holder making sure the accessory engages all

eight pins on the holder and is ush with the shaft.

● Release the accessory clamping lever.

Note: Some accessories, such as scrapers and blades can be

mounted at an angle if required (g. C).

Removing a STANLEY FATMAX accessory accessory

(g. A)

● Hold the tool and squeeze the accessory clamping

lever (3).

● Pull the accessory from the tool making sure the

accessory dis-engages from all eight pins on the holder.

● Release the accessory clamping lever.

@

Warning! Gloves must be worn when removing

accessories as then may become hot during use.

Fitting a sanding sheet (g. D)

● Line up the sanding sheet (10) with the sanding base (4)

as shown.

● Press the sheet rmly and evenly onto the sanding base,

making sure that the holes in the sheet coincide with the

holes in the base.

Removing a sanding sheet

● Pull the sanding sheet off the sanding base (4).

@

Warning! Never use the sanding base without a

sanding sheet or accessory in place.

Fitting the dust extraction adaptor (g. E)

● Line up the dust extraction adaptor (5) with the sanding

base (4) as shown.

● Press the adaptor rmly and evenly in to the

sanding base.

● Secure the adaptor by turning the locking

nut (11) clockwise.

● Connect a vacuum cleaner to the dust extraction adaptor.

Removing the dust extraction adaptor

● Turn the locking nut (11) anti-clockwise.

● Pull the dust extraction adaptor (5) out of the sanding

base (4).

Fitting the depth/cut guide (g. F)

The depth/cut guide allows you to precisely cut material at a

specied depth and more accurately track a marked cut line.

● Attach the depth/cut block (8) by inserting the tabs on the

guide into the slots on the main body.

● Secure the block to the main body with the bolt (12) and

tighten with the supplied hex wrench.

● Insert the guide (13) into the requried position and secure

by turning the depth/cut adjustment knob (14) clockwise.

Fitting alternative accessories (g. G)

● Place the spacer (6) onto the collar (15).

● Place the alternative accessory (16) onto the collar (15).

● Firmly attach the xing bolt (7) into place to ensure a tight

t for the alternative accessory (16).

Note: The spacer and xing bolt are not used to attach

STANLEY FATMAX accessories. STANLEY FATMAX

accessories are attached using the Super-lok

TM

Tool free

accessory clamping lever.

Use

@

Warning! Let the tool work at its own pace. Do

not overload.

@

Warning! Before cutting into walls, oors or ceilings,

check for the location of wiring and pipes.

Variable speed control (g. H)

The variable speed control allows you to adapt the speed of

the tool to the application.

● Set the variable speed dial (2) to the desired setting. At

setting 1 the tool will operate at low speed, 10,000 min

-1

.

At setting 6 the tool will operate at the maximum speed,

22,000 min

-1

.

Switching on and off (g. I)

● To switch the tool on, slide the on/off switch (1) forward

(position I).

● To switch the tool off, slide the on/off switch (1) to the rear

(position O).

Cut guide (g. F & J)

This feature allows you to more accurately track a marked

cut line.

● To use the cut guide, insert the guide (13) as shown in

gure J into the front slot on the depth/cut guide block (8).

Loading...

Loading...