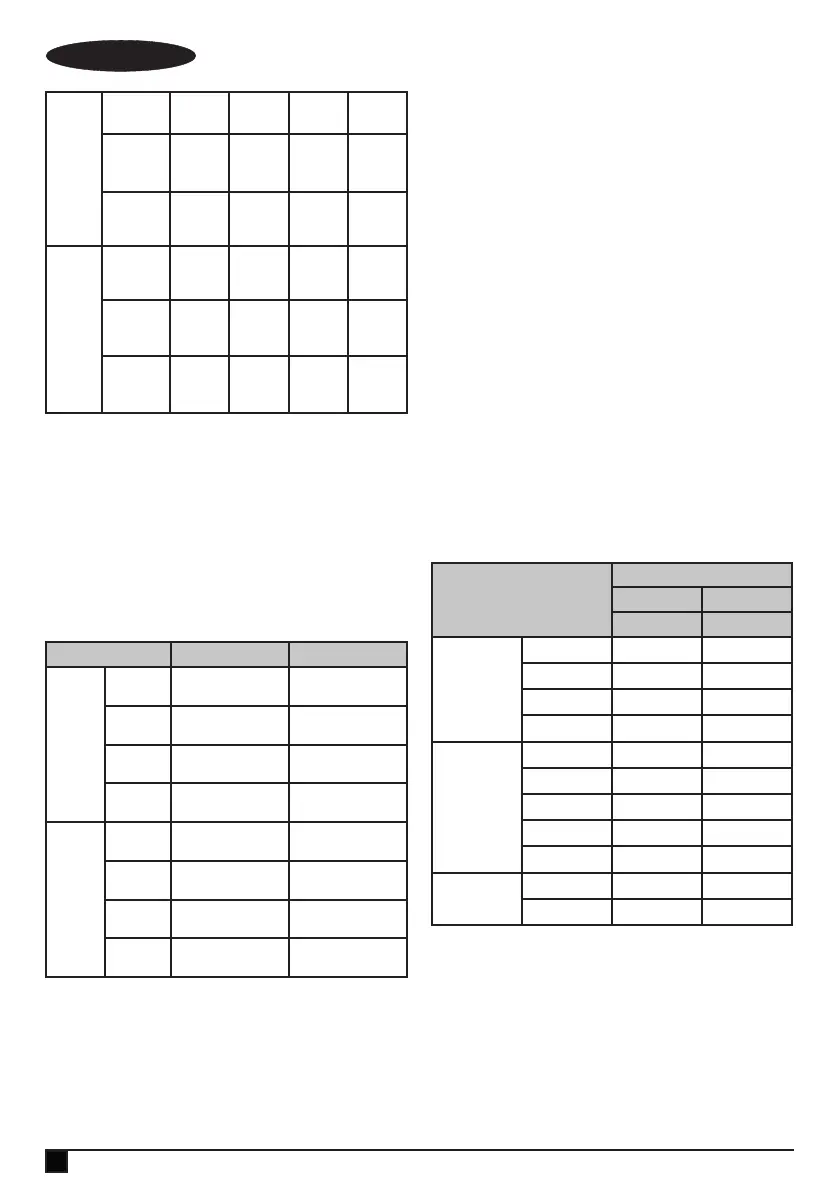

Inside

corner

Mitre angle

Left at

45 º

Right at

45 º

0 º 0 º

Moulding

position

Bottom

against

table

Bottom

against

table

Top

against

nce

Bottom

against

fence

Finished

side

Keep left

side of

cut

Keep

right side

of cut

Keep left

side of

cut

Keep left

side of

cut

Outside

corner

Mitre angle

Left at

45 º

Right at

45 º

0 º 0 º

Moulding

position

Bottom

against

table

Bottom

against

table

Top

against

nce

Bottom

against

fence

Finished

side

Keep left

side of

cut

Keep

right side

of cut

Keep

right side

of cut

Keep

right side

of cut

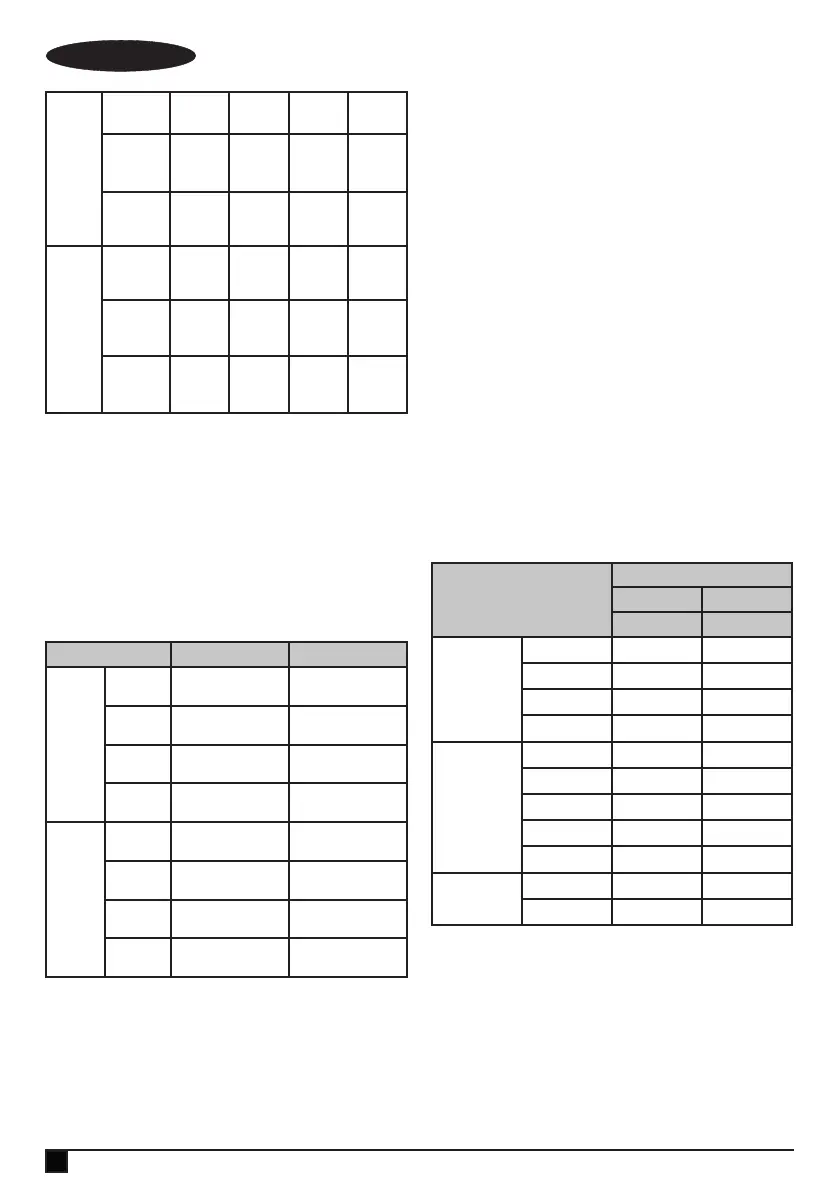

Crown moulding cut (g. L)

Crown moulding can only be cut at on the table with this

mitre saw.

● This mitre saw has special mitre stops on 31.6° left and

right and a bevel stop of 33.9° for special crown moulding,

i.e. 52° between the back of the moulding and the top

at surface that ts against the ceiling; 38° between the

back of the moulding and the bottom at surface that ts

against the wall.

● Refer to the following table to make this crown

moulding cut:

Settings Left side Right side

Inside

corner

Mitre

angle

Right 31.6 º Left 31.6 º

Bevel

angle

33.9 º 33.9 º

Moulding

position

Top against fence Bottom against fence

Finished

side

Keep left side of cut Keep left side of cut

Outside

corner

Mitre

angle

Right 31.6 º Left 31.6 º

Bevel

angle

33.9 º 33.9 º

Moulding

position

Bottom against fence Top against fence

Finished

side

Keep right side of cut Keep right side of cut

Note: These special stops can not be used with 45°

crown moulding.

Note: Since most rooms do not have angles of exactly 90°,

ne tuning is needed, always make a test cut to conrm the

correct angles.

Setting the cutting depth (g. M)

The depth of cut can be preset for even and repetitive

shallow cuts.

● Adjust the cutting head down until the teeth of the blade

are at the required depth of cut.

● While holding the upper arm in position, turn the

stop knob (47) until it touches the stop plate (49).

● Check the blade depth by moving the cutting head front

to back through the full motion of a typical cut along the

control arm.

Carrying the tool (g. B, J, H, N)

● Loosen the mitre detent lever (11) (g. B) and turn the

table all the way to the right. Lock the table at the 45°

mitre angle.

● Pull the cutting head to the front of the saw and lock the

carriage with the lock knob (48) (g. J).

● Lower the cutting head and push in the lock pin (46)

(g. H).

● Carry the mitre saw with the front and the rear carrying

handles (24, 27).

@

Warning! Do not carry the machine by the guard.

Blade and tooth type

Material

Tooth type

600 ~ 100T 24 ~ 100T

TCG ATB

Wood

Lumber ● ●

Plywood ● ●

Hardwood ● ●

Chipboard ● ●

Plastic

PVC ●

ABS ●

Acrylic ●

PC ●

PS ●

Non-ferrous

metal

Aluminium ●

Copper ●

Your mitre saw has been supplied with a negative rake saw

blade. It is advisable to use a negative rake saw blade.

● TCG type - For cutting aluminium sheets, tubing

extrusions and other non-ferrous metals such as

copper, brass.

● ATB type - For general cutting and trimming of wood,

plywood, and sizing pressboard, hardboard, and particle

board, when a neat cut is needed.

Always use a negative rake blade when cutting non-

ferrous metals.

14

ENGLISH

(Original instructions)

Loading...

Loading...