8 9

and the Clamp Icons with the “+” and ”–” signs. The Alarm Icon and the Jump

Starter Icon will flash. The backlit LCD screen will display the following:

Turn off the Jump Starter Power Switch; connect the clamps to the battery, making

sure the clamps are connected with correct polarity; then turn the Jump Starter Power

Switch back on.

• Always disconnect the negative (black) jumper cable first, followed by the positive

(red) jumper cable, except for positive grounded systems.

Procedure

Take the following steps, observing all cautions and warnings in the “Important

Safety Instructions” section at the front of this manual.

1. Turn off vehicle ignition and all accessories (radio, A/C, lights, connected cell

phone chargers, etc.). Place vehicle in “park” and set the emergency brake.

2. Make sure the jump-starter power switch is in the off position.

3. Remove jumper clamps from clamp tabs. Connect the red clamp first, then the

black clamp.

4. Procedure for jump-starting a NEGATIVE GROUNDED SYSTEM (negative

battery terminal is connected to chassis) (MOST COMMON)

4a. Connect positive (+) red clamp to vehicle battery’s positive terminal.

4b. Connect negative (–) black clamp to chassis or a solid, non-moving, metal

vehicle component or body part. Never clamp directly to negative battery

terminal or moving part. Refer to the automobile owner’s manual.

5. Procedure for jump-starting POSITIVE GROUND SYSTEMS

Note: In the rare event that the vehicle to be started has a Positive Grounded System (positive battery

terminal is connected to chassis), replace steps 4a and 4b above with steps 5a and 5b, then

proceed to step 6.

5a. Connect negative (–) black clamp to vehicle battery’s negative terminal.

5b. Connect positive (+) red clamp to vehicle chassis or a solid, non-moving,

metal vehicle component or body part. Never clamp directly to positive

battery terminal or moving part. Refer to the automobile owner’s

manual.

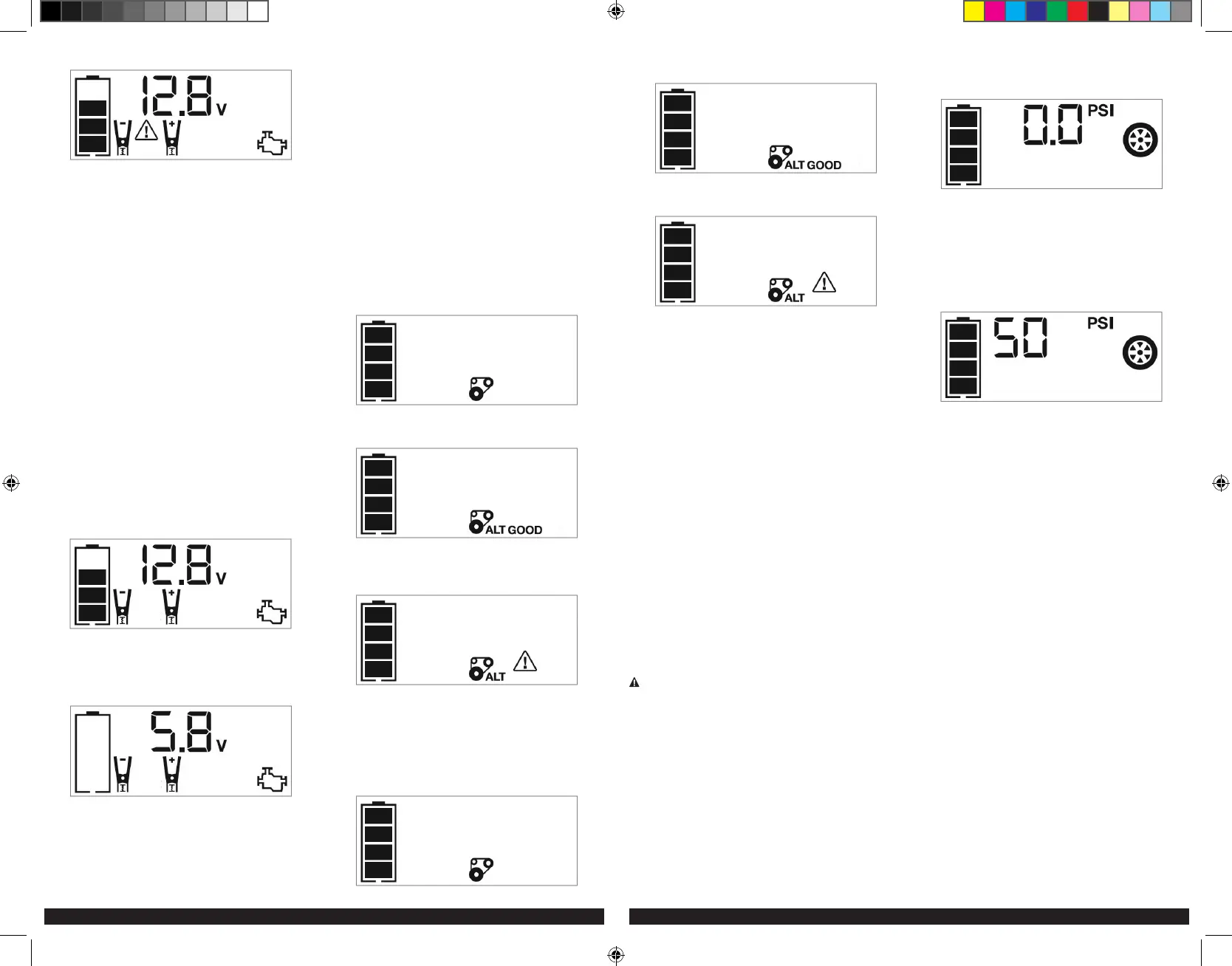

6. When the clamps are connected properly, the unit will automatically turn on in

jump-starter mode. The backlit LCD screen will display the following to indicate

the unit is ready to jump-start:

The Battery Status icon, Battery Voltage Indicator, Clamp Icons and the “+” and

”–” signs light solid. The jump starter icon will flash to indicate the clamps are

properly connected.

7. Turn the Jump-Starter Power Switch on. Turn on the ignition and crank the

engine in 5-6 second bursts until engine starts. The backlit LCD screen will

display the following:

8. The Battery Status Icon, the Battery Voltage Indicator, Jump Starter Icon,

Clamp Icons and the “+” and ”–” signs light solid to indicate the unit is jump-

starting.

9. Turn the Jump-Starter Power Switch off.

10. Disconnect the negative (–) engine or chassis clamp first, then disconnect the

positive (+) battery clamp.

IMPORTANT: Always turn the unit off when not in use. Recharge this unit fully

after each use.

NOTICE – TO REDUCE THE RISK OF PROPERTY DAMAGE:

• Vehicles that have on-board computerized systems may be damaged if vehicle

battery is jump-started. Before jump-starting this type of vehicle, read the vehicle

manual to confirm that external-starting assistance is advised.

• Excessive engine cranking can damage the vehicle‘s starter motor. If the engine

fails to start after the recommended number of attempts, discontinue jump-start

procedure and look for other problems that need to be corrected.

• If vehicle fails to start, turn off the ignition, turn off the Jump-Starter Power

Switch, disconnect the jump-start system’s leads and contact a qualified technician

to investigate why the engine did not start.

ALTERNATOR CHECK

Set up the unit and connect to the battery following steps 1 through 5 in the

“Jump-Starter” section.

Part 1

No Load (turn OFF all vehicle’s accessories): The vehicle battery must be fully

charged before testing the alternator. Run the engine long enough to achieve

normal idle speed and verify there is a no-load voltage.

1. Press the Alternator Check Button to start the check. The backlit LCD screen will

display the following to indicate the unit is analyzing the alternator:

The Battery Status Icon will light solid and the Alternator Icon will flash.

2. If the unit detects that the alternator is good, the backlit LCD screen will

display the following:

The Battery Status Icon, Alternator Icon, and “ALT GOOD” will light solid.

3. If the unit detects that the alternator is out of typical voltage range, the backlit

LCD screen will display the following:

4. The Battery Status Icon, Alternator Icon and “ALT” will light solid. The Fault

Icon will flash.

5. Press the Alternator Check Button again to stop the test and turn off the unit.

Part 2

Under Load (accessories ON): Next, load the alternator by turning on as many

accessories as possible (except for A/C and Defrost).

1. Press the Alternator Check Button to start the check. The backlit LCD screen will

display the following to indicate the unit is analyzing the alternator:

The Battery Status Icon will light solid and the Alternator Icon will flash.

2. If the unit detects that the alternator is good, the backlit LCD screen will

display the following:

The Battery Status Icon, Alternator Icon, and “ALT GOOD” will light solid.

3. If the unit detects that the alternator is out of typical voltage range, the backlit

LCD screen will display the following:

The Battery Status Icon, Alternator Icon and “ALT” will light solid. The Fault

Icon will flash.

4. Press the Alternator Check Button again to stop the test and turn off the unit.

IMPORTANT: Always turn the unit off when not in use. Recharge this unit fully

after each use.

Notes: The unit may detect that the alternator is out of typical voltage range because someone has added

a number of accessory loads on the charging system, thereby increasing current demand from the

alternator. MAKE SURE THAT THE ALTERNATOR IS RATED TO SUPPORT THE APPLICATION.

This check may not be accurate for every make, manufacturer and model of vehicle. Check only 12

volt systems.

PORTABLE COMPRESSOR

The built-in 12 volt DC compressor is the ultimate compressor for all vehicle tires,

trailer tires and recreational inflatables. A nozzle adaptor is supplied that screws

onto the end of the Sure Fit

®

nozzle at the free end of the compressor hose.

The compressor hose with tire fitting is stored in the compressor hose storage

compartment. Refer to the “Features” illustration for locations of compressor hose.

The Compressor Power Button and Compressor Pressure Control Buttons are located

on the control panel on the front of the unit.

Before proceeding, check the unit’s battery status on the LCD screen. Four solid bars

in the battery icon indicates a full battery. When the battery level is nearly empty

with only one solid bar, the unit MUST be recharged before use or the unit’s built-in

low voltage protection will activate. The empty Battery Status Icon will flash for a

short period of time before automatic shut down.

The compressor may be used by removing the air hose from the storage hatch and

if required, fitting the nozzle adapter to the air hose. The compressor is capable

of inflating up to 120 pounds per square inch (psi) pressure. The compressor can

operate long enough to fill up to 3 average sized tires before the battery must be

recharged. Return hose to the storage compartment after use.

IMPORTANT: Make sure the Jump Starter Power Switch has been turned off before

attempting to use the unit as a Compressor.

WARNING – TO REDUCE THE RISK OF INJURY OR PROPERTY DAMAGE:

Follow all safety instructions found in the “Specific Safety Instructions For

Compressors” section of this instruction manual.

NOTICE – TO REDUCE THE RISK OF PROPERTY DAMAGE:

When the compressor is operated at a low PSI, the unit may start in low and

gradually rev up. When the compressor is operated at higher PSIs, the unit may

operate normally for several minutes, then rev down for a few minutes before

returning to normal operation. This feature protects the unit from overheating

during normal use. In any event, do not operate compressor continuously for

extended periods of time (approximately 10 minutes, depending on ambient

temperatures), as it may overheat. This could damage the compressor. If the

compressor must be operated for longer periods: every 10 minutes press the

Compressor Power Button to turn the compressor off, then restart after a cooling

down period of approximately 30 minutes.

In any event, the compressor will automatically shut down after operating

continuously for 10 minutes.

Inflating Tires or Products With Valve Stems

1. Screw the Sure Fit

®

nozzle onto the valve stem. Do not overtighten.

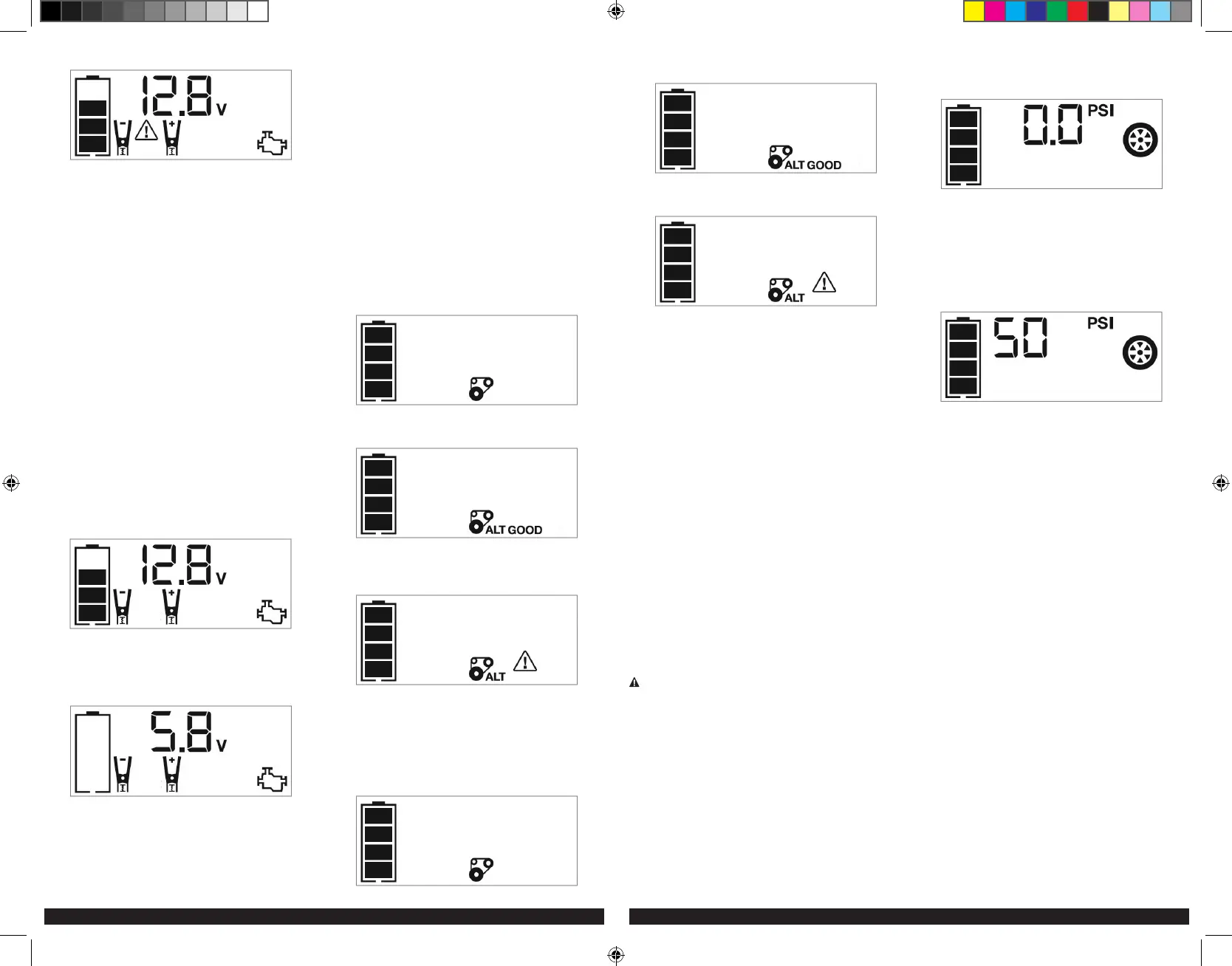

2. Press the Compressor Power Button. A beep will sound and the backlit LCD

screen will display the following:

The Compressor Icon will light and the digital display will alternately show the

flashing pre-set psi value (that was last set by the compressor pressure control

buttons) and the current pressure of the item being inflated (which will light

solid).

3. Press the “+” and “–” Pressure Control Buttons to set the desired pressure from

a range pre-set values (between 3 and 120), which will display on the backlit

LCD screen. The unit will sound a beep with each press of the buttons (holding

the button speeds up the upward or downward value selection). Once the

desired pressure has been entered, release the button and the flashing digital

display will show the new selected pressure, as follows:

The new selected value is now stored in the unit’s memory until it is manually

reset.

4. Press the Compressor Power Button once more to begin inflating. The

Compressor Icon will flash and the digital display will only show the current

pressure value (which will light solid) to indicate the compressor is activated.

Monitor the pressure on the LCD screen.

IMPORTANT NOTE: To interrupt during inflation, press the Compressor Power

Button again.

5. When desired pre-set pressure is reached, the compressor will automatically

stop.

6. Press the Compressor Power Button again to turn off the unit.

7. Unscrew and remove the Sure Fit

®

nozzle from the valve stem.

8. Allow the unit to cool, then recharge before storing away.

9. Store the compressor hose and Sure Fit

®

nozzle in storage compartment.

Inflating Other Inflatables Without Valve Stems

Inflation of other items requires use of the nozzle adapter.

1. Screw the nozzle adapter into the Sure Fit

®

nozzle. Do not overtighten.

2. Insert the nozzle adapter into item to be inflated.

3. Follow steps 2 through 4 of the “Inflating Tires or Products With Valve

Stems” section.

IMPORTANT: Small items such as volleyballs, footballs, etc. inflate very rapidly.

Keep this in mind when setting pressure. Take extra care not to over-inflate.

4. When the desired pressure is reached, the compressor will automatically stop.

Press the Compressor Power Button again to turn off the unit.

5. Disconnect the adapter from the inflated item.

6. Unscrew and remove the nozzle adapter from the Sure Fit

®

nozzle.

7. Allow the unit to cool, then recharge before storing away.

8. Store the compressor hose, Sure Fit

®

nozzle and nozzle adapter in the storage

compartment.

USB PORTS

The USB Power Button and the four USB Ports are located on the left hand side of

unit. The USB Power/Fault Indicator is a translucent ring around each of the four

USB Ports. Refer to the “Features” section to locate.

IMPORTANT NOTES:

The top two USB Ports provide a total of 3.1A (5V each). The bottom two USB Ports

provide a total of 3.1A (5V each).

When the USB Ports are in use, the unit will monitor for the following USB fault

conditions on all the USB Ports: low battery voltage fault, overload and short

PP1DCS_ManualENSP_040721.indd 8-9PP1DCS_ManualENSP_040721.indd 8-9 4/7/2021 11:58:05 AM4/7/2021 11:58:05 AM

Loading...

Loading...