8

ENGLISH

2. Do not touch the blade or the workpiece immediately

after operation, they may be extremely hot and could burn

your skin.

3.Always secure the blade firmly. Insufficient tighten of

the blade may cause blade breakage or serious personal

injury.

4. Use only T type blades. Using blades other than T type

blades cause insufficient tightening of the blade, resulting

in a serious personal injury.

5. Use suitable saw blade for different type of the

workpieces for getting better cutting result.

Connecting a vacuum cleaner to the tool (Fig.C)

♦ Slide the vacuum nozzle (14) into the dust extraction

outlet (10).

Residual risks

Additional residual risks may arise when using the tool

which may not be included in the enclosed safety warnings.

These risks can arise from misuse, prolonged use etc.

Even with the application of the relevant safety regulations

and the implementation of safety devices, certain residual

risks can not be avoided. These include:

♦ Injuries caused by touching any rotating/moving parts.

♦ Injuries caused when changing any parts, blades or

accessories.

♦ Injuries caused by prolonged use of a tool. When using

any tool for prolonged periods ensure you take regular

breaks.

♦ Impairment of hearing.

♦ Health hazards caused by breathing dust developed

when using your tool (example:- working with wood,

especially oak, beech and MDF.)

USE

Adjusting the shoe plate for bevel cuts (Fig. D)

Warning! Never use the tool when the shoe plate is

loose or removed. Always secure the shoe plate firmly

before using power tool. Insufficient tightening of the shoe

plate may cause serious personal injury.

The shoe plate (9) can be set to a left or right bevel angle

of 45°.

♦ Lift dust cover (4).

♦ Loosen the two screws-shoe plate (15).

♦ Pull the shoe plate (9) forward, rotate the shoe plate to

the left or right and push it back into the 45° location.

♦ Tighten the screws-shoe plate (15).

To reset the shoe plate for 0° cuts:

♦ Loosen the two screws-shoe plate (15).

♦ Pull the shoe plate (9) forward, rotate to the centre and

push it back into the 0° location.

♦ Tighten the screws-shoe plate (15).

♦ Turn down dust cover (4).

♦ WARNING: Turn down the dust cover to prevent chips

from flying. However, when making bevel cuts, lift it

all the way.

Variable speed control:

♦ (SJ60)(Fig.A-1): A speed controller (3) is located on

the top of the Jigsaw. The speed increases as the

wheel is turned from a low speed setting of 1 to a high

speed setting of 6.

♦ (SJ45)(Fig.E): A speed controller (3) is located on the

top of the trigger switch. Turn the speed controller to

“+” direction to increase speed and turn the speed

controller to “-” direction to decrease speed.

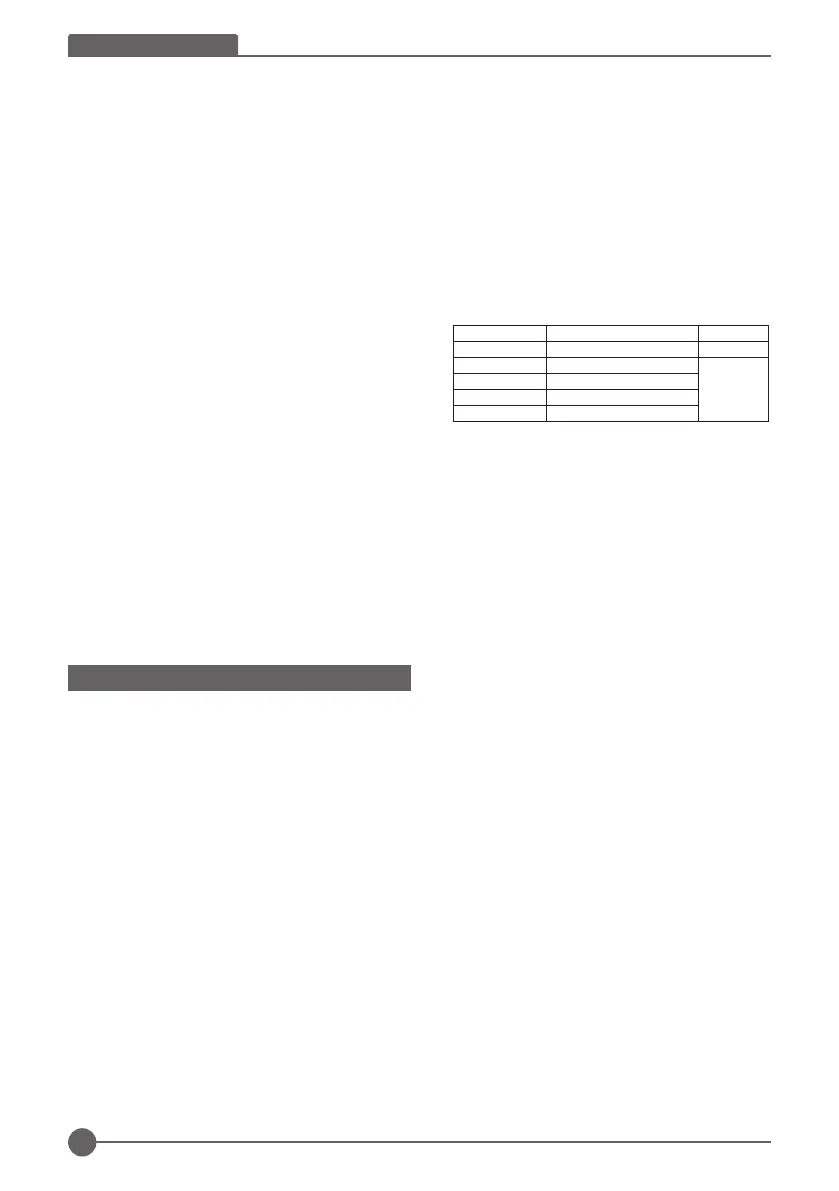

♦ Refer to the table to select the proper speed for the

workpiece to be cut. However, the appropriate speed

may differ with the type or thickness of the workpiece. In

general, higher speeds will allow you to cut workpieces

faster but the service life of the blade will be reduced.

Workpiece to be cut

Wood high speed

medium speed

5-6

3-4

3-6

3-6

1-4

Stainless steel

Mild steel

Aluminum

Plastics

Number on speed controller-SJ60 Speed of SJ45

♦ WARNING: If the tool is operated continuously at low

speeds for a long time, the motor will get overload and

heated up.

Switching on and off (Fig.A-1,Fig.A-2)

♦ To switch the tool on, press the trigger switch (1).

♦ For continuous operation, press the trigger switch (1),

then press the lock-on button (2).

♦ To switch the tool off, release the trigger switch. To

switch the tool off, when in continuous operation,

press the trigger switch once more and release it.

How to Use the Sightline Feature (Fig. F)

♦ Use a pencil to mark the cutting line.

♦ Position the jig saw over the line (16).

♦ Viewing from directly above the jig saw, the line of cut

can be followed easily.

Cutting mode (SJ60 only)

♦ Pendulum stroke or action provides a more aggressive

blade motion and is designed for cutting soft materials

such as wood or plastic. It provides a faster cut, but

with a less smooth cut across the material. Your jig

saw has a Pendulum Stroke dial. Use of this dial is

explained in the next section.

♦ Warning: Never use pendulum action to cut metal.

Pendulum Stroke dial (Fig. G - SJ60)

♦ The SJ60 has these four cutting modes with increasing

amounts of pendulum action:

♦ Position 0: metal and aluminium and sheet metal (no

pendulum action).

♦ Position I: for laminates, hard wood, work tops.

♦ Position II: for plywood and PVC/Plastics.

♦ Position III: for soft wood and fast cutting

To adjust the pendulum action (Fig.G):

♦ Rotate the Pendulum Stroke selector (8) to the

required position.

Loading...

Loading...