Inspection and other services should always be

carried out on hard and level ground with the engine

shut down.

Inspection and Maintenance Service Tables.

To make sure your plate compactor is always in good

working condition before using , carry out the

maintenance inspection in accordance with Tables 1

through 3.

TABLE 1.MACHINE INSPECTION

Function of controlling system

part

(For details, see separate engine Manual)

Tightness of fastening

Threads

Engine oil check and

replenishment

Every 8 hours(every day)

(Replenish to specified

Max.level)

At first 20 hours.Then every

100 hours

CAUTION:

These inspection intervals are for

operation under normal

conditions.Adjust your inspection

intervals based on the number

hours plate compactor is in use,

and particular working conditions.

CAUTION:

Fuel piping and connections should

be replaced every 2 years.

Daily Service

● Check for leakage of fuel or oil.

●Remove soil and clean the bottom of compaction

plate.

●Check engine oil.

Check for loose screws including tightness.See Table

3 below(tightening torque),for re-tightening.

TABLE 3.

TIGHTENING TORQUE(in.kg/cm)Diameter

Changing Vibrator Oil

when changing the vibrator oil,remove the drain plug

100(6mm) 300-350(8mm) 650-700(10mm)

* (In case counter-part is of aluminum

(Threads in use with this machine are all right handed)

Material and quality of material is marked on each bolt, and

screw.

Changing Vibrator Oil

When changing the vibrator oil, remove the drain plug

located at the bottom-right of the vibrator, and simply

tip the compactor to drain the oil.Note that the oil will

drain more easily while it is hot.Replace the oil with

200ML of 10W-3C motor oil.

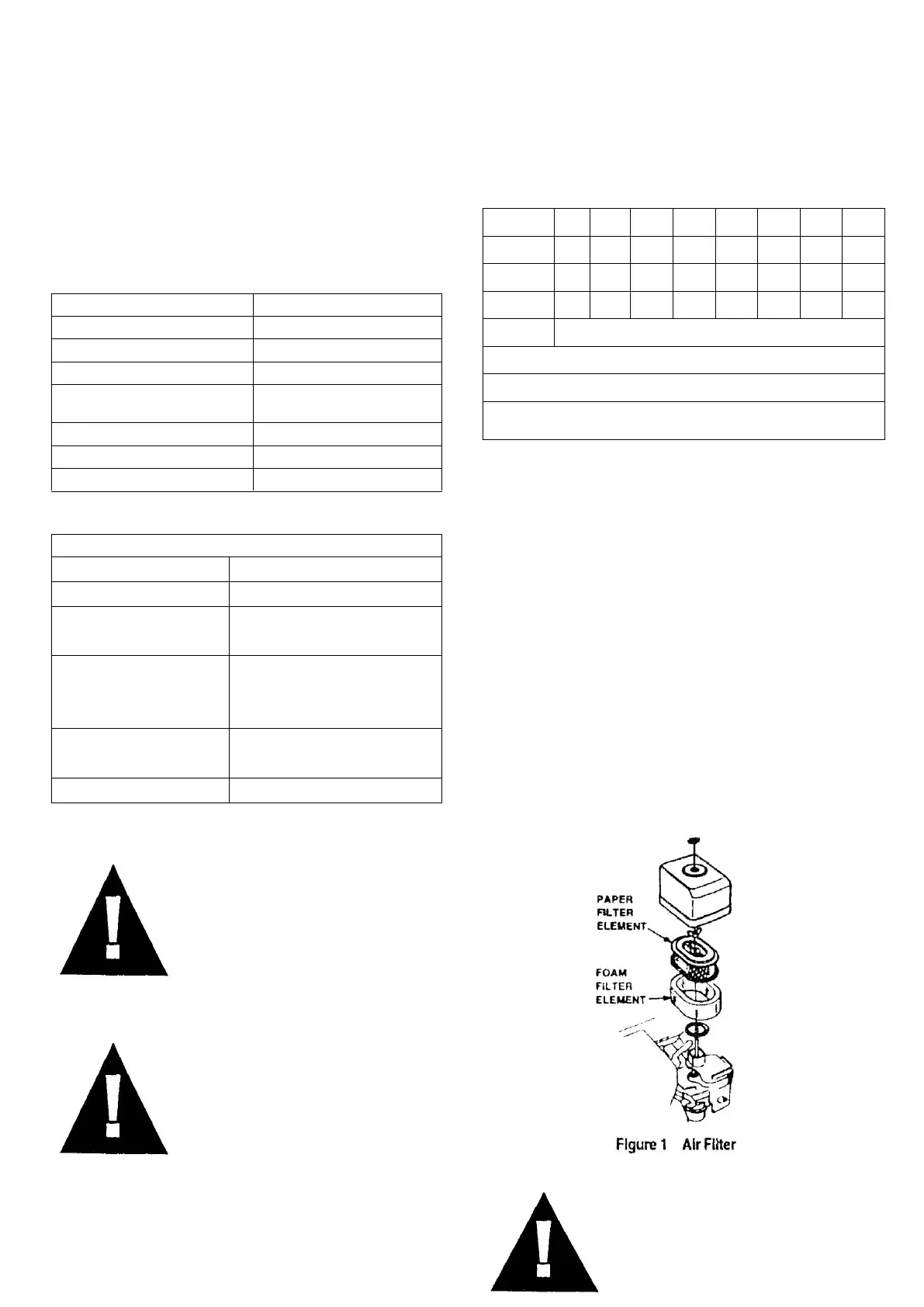

Air Filter

1.The air filter element should be cleaned because a

clogged air cleaner can cause poor engine starting,

lack of power and shorten engine Iife substantially.

2.To clean or replace air filter loosen the wing nut on

the air filter housing(Figure 1),remove the cover

and take out air filter cartridge.If only cleaning of

the air filter is desired blow through the air filter

cartridge from the inside, moving a jet of dry

compressed air up and down until all dust is

removed.

CAUTION:

NEVER attempt to check the V-belt

with the engine running.Severe

injury can occur if your hand gets

Loading...

Loading...