4. Using The Machine

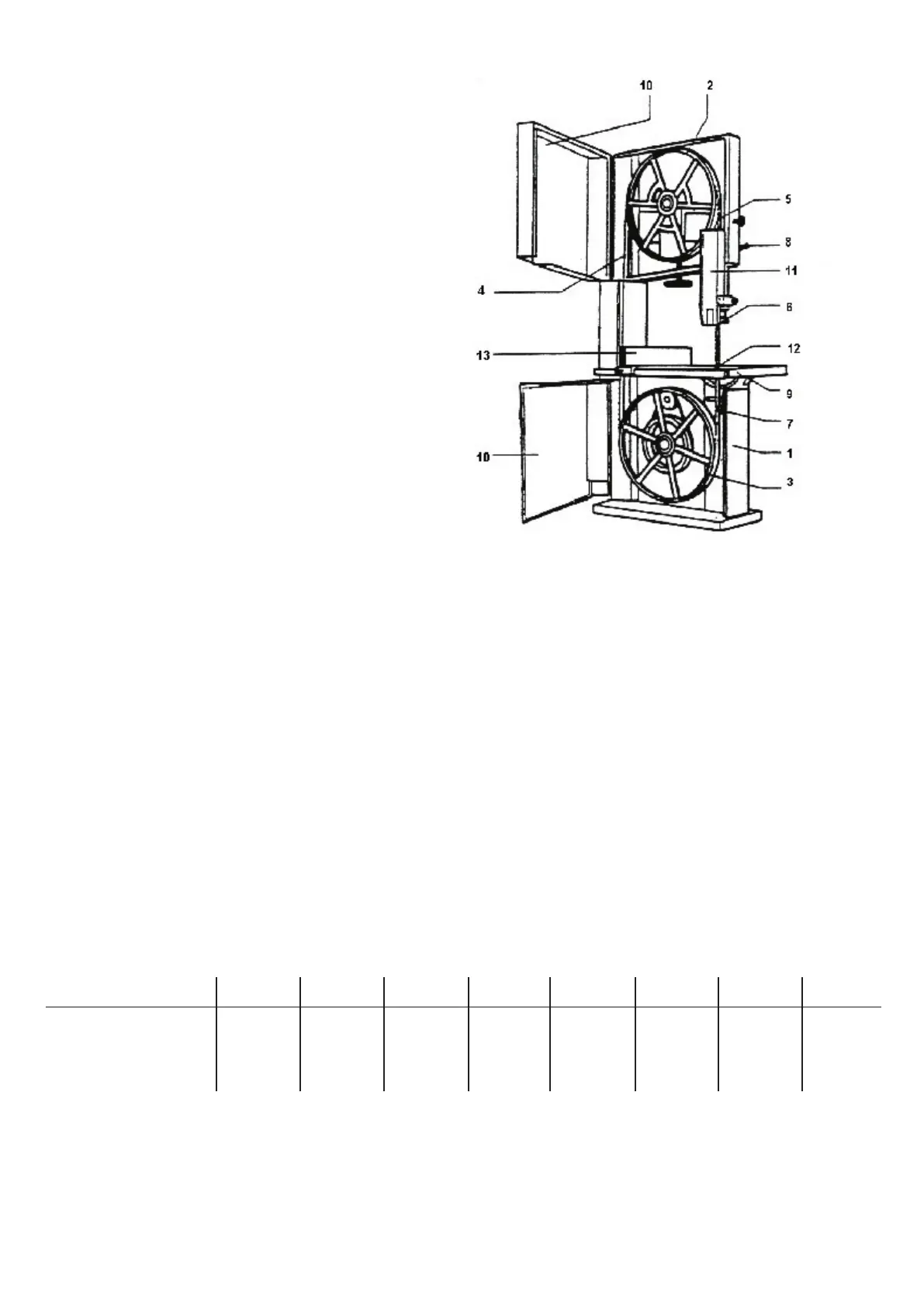

4.1 PRINCIPAL MACHINE PARTS

1 Base

2 Upper bandwheel

3 Lower bandwheel

4 Blade upward portion

5 Blade downward portion

6 Upper blade guide

7 Lower blade guide

8 Blade guide height adjustment

9 Table

10 Bandwheel door guard

11 Adjustable blade guard

12 Table insert

13 Rip fence

ATTENTION!! DISCONNECT THE ELECTRICAL SUPPLY

BEFORE EVERY ADJUSTMENT

ATTENTION!! IN CASES OF BLADE BREAKAGE WAIT UNTIL

THE UPPER

BANDWHEEL HAS COMPLETELY STOPPED

BEFORE OPENING THE DOOR.

4.2 CHOICE AND MAINTENANCE OF BLADES

The table below defines the blade length and maximum width, depending on the type of the machine.

Selection of width and type of tooth depends upon the materials to be cut and the type of operation, narrow blades are suitable for

cutting curved lines, profiles etc.., wide blades are best for straight cutting.

It is advisable to use finer teeth for hard woods or thin material and coarser teeth for softwoods or deep material. In every case, the

distance between each tooth should be sufficient to clear the sawdust produced during the cutting operation. If the clearance is not

correct this can cause overheating and jamming of the blade, causing subsequent breakage .

Do not use flawed or deformed blades.

It is highly recommended that the blade be changed regularly. Use a specialised saw doctor for welding, sharpening and re-setting

blades. The use of high quality blades is also recommended

Causes of blade breakage:

• Excessive blade thickness in relation to the bandwheel size.

• Defective welding

• Incorrect tension, particularly if the blade is over tensioned the tension spring no longer fulfils its function

• Overloading the blade caused by using a badly ground or badly set blade, or by not slackening the tension

• After use it is recommended to slacken the tension, especially overnight, (placing a visible notice of this operation on the machine).

Re-tension before next next operation.

• Misalignment of the bandwheels due to unauthorized intervention of the regulating screws of the lower bandwheel.

• Irregularity of bandwheels surface, e.g an accumulation of sawdust whilst cutting resinous materials.

352SB* 401S 440R 501S 581S 681S 781S

Blade Length (Min) 3560mm / 141” 3850 4060mm / 160” 4170mm / 165” 4610mm / 182” 5100mm / 201” 5750mm / 227”

Blade Length (Max) 3640mm / 143” 4170mm / 164” 4280mm / 168” 4680mm / 184” 5150mm / 203” 5820mm / 229”

Blade Width mm 6 - 30 6 - 30 6 - 50 6 - 35 6 - 35 6 - 40 6 - 45

401E

Blade Length 3850mm

Blade Width mm 6 - 30

Loading...

Loading...