4.5 TABLE INSERT FOR DUST EXTRACTION

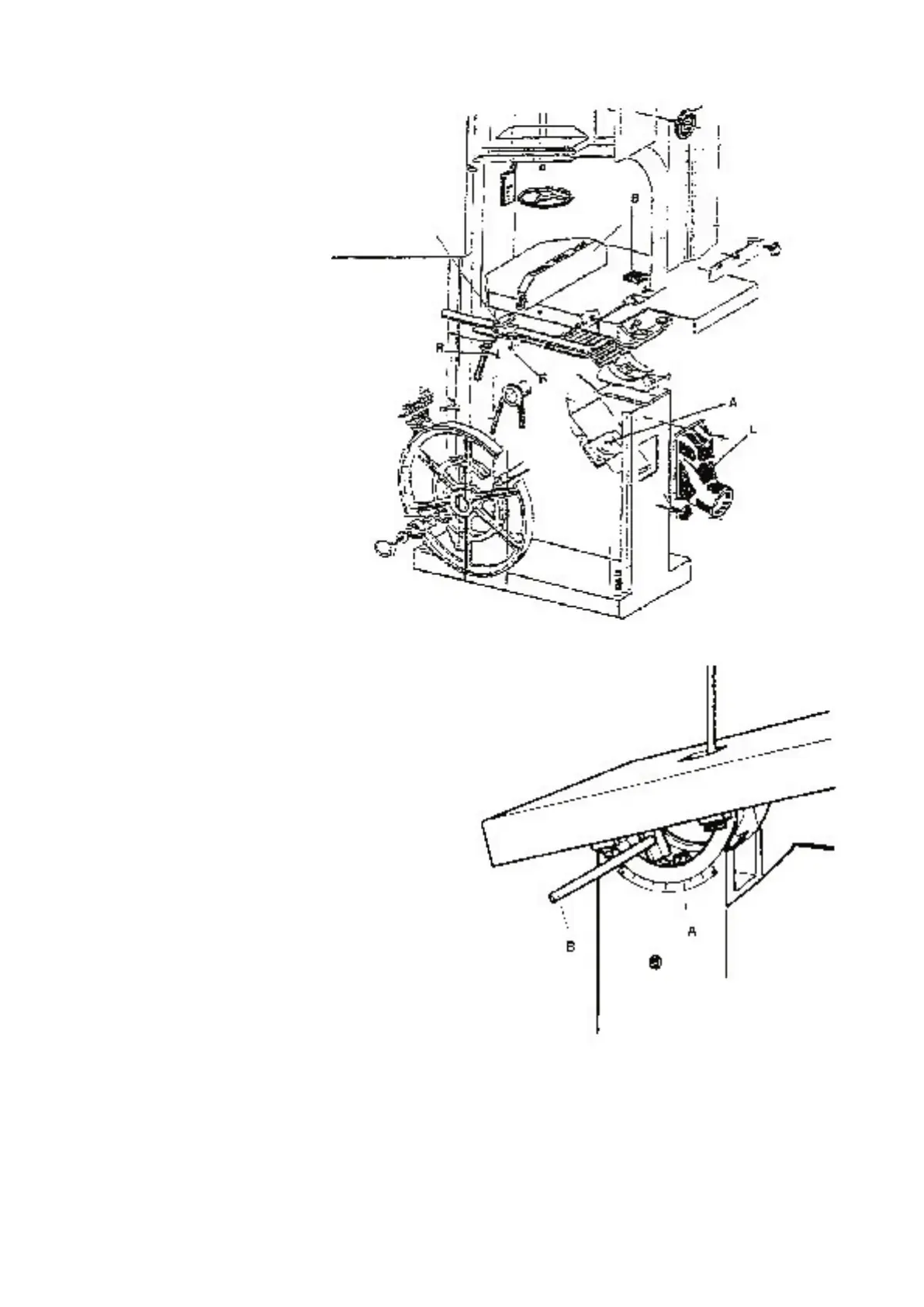

4.7 TILTING THE WORK TABLE

The table can be tilted to a maximum of 20°

To incline it, loosen off the locking ratchet handle FIG. 21

position B. Use the box spanner provided to turn rack and pinion

mechanism FIG. 21 position A. Turn until table is at required angle.

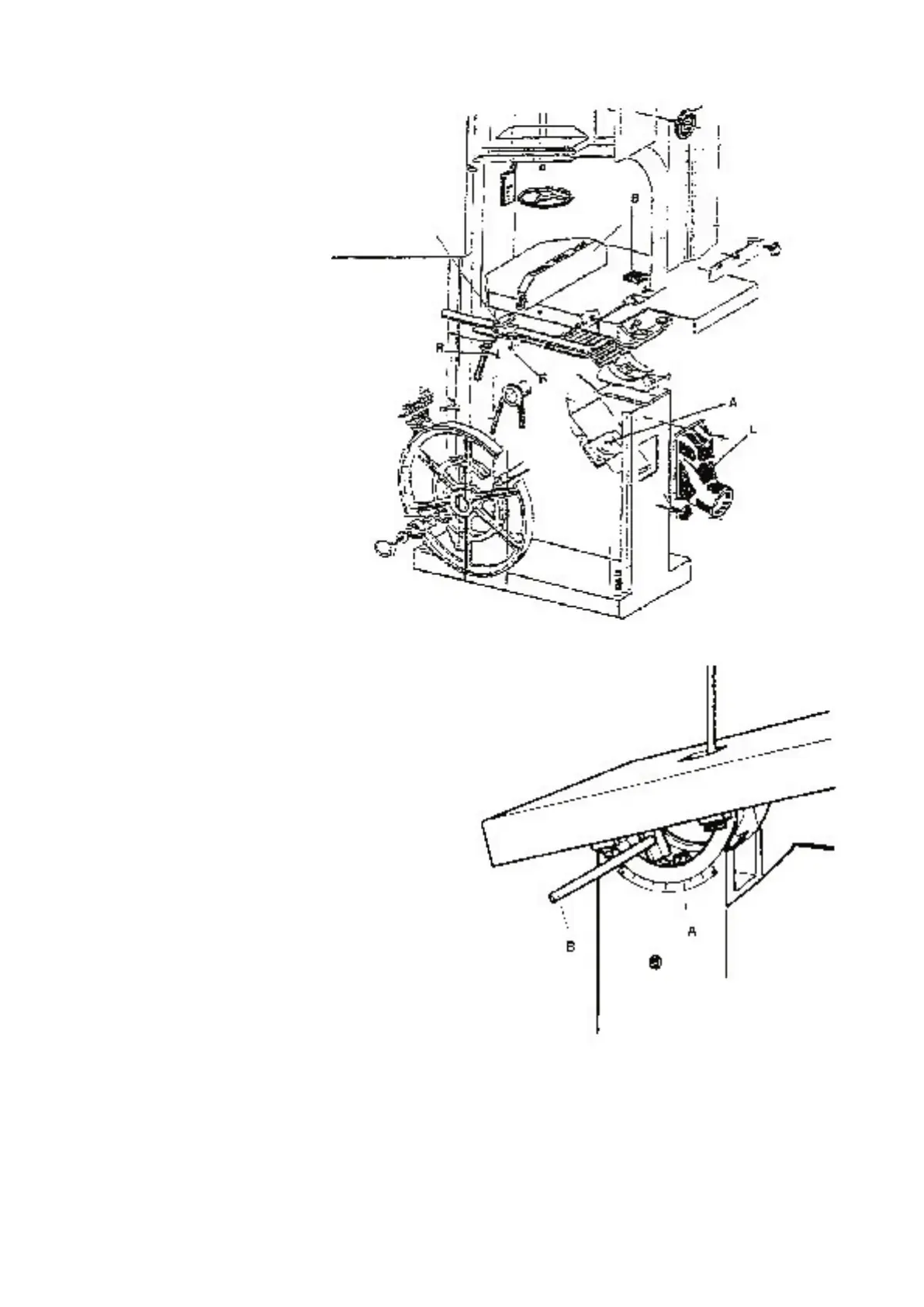

The machines are equipped with a

removable plastic insert on the work-

table, FIG.20, pos “B”, the relieved holes

of the insert improve dust extraction.

By adjusting the 4 screws at the bottom

of the opening of the work-table it is

possible to change the height of the

insert in relation to the work surface.

Models with fly-wheels up to 600 mm

diameter have one extraction outlet,

models with larger diameters have a

second outlet fitted on the base , under

the work-table ( FIG. 20, pos “

L” ).

It is recommended that the insert “ A

“ be replaced when the blade cutting

clearance widens, this will maintain

maximum efficiency of dust extraction.

4.6 CUTTING DIRECTION

AND PARALLELISM

If the cut is not perfectly parallel when

using the parallel rip fence the possible

causes are:

• Incorrect grinding and setting

of the blade

• Insufficient blade tension

• Incorrect setting of the parallel rip fence

in respect of the blade; to adjust the

parallelism of the guide, slacken, without

removing, the 2 screws “

R “, FIG. 20,

adjust the guide position and re-tighten,

firmly, the 2 screws

FIG. 20

FIG. 21

Loading...

Loading...