10

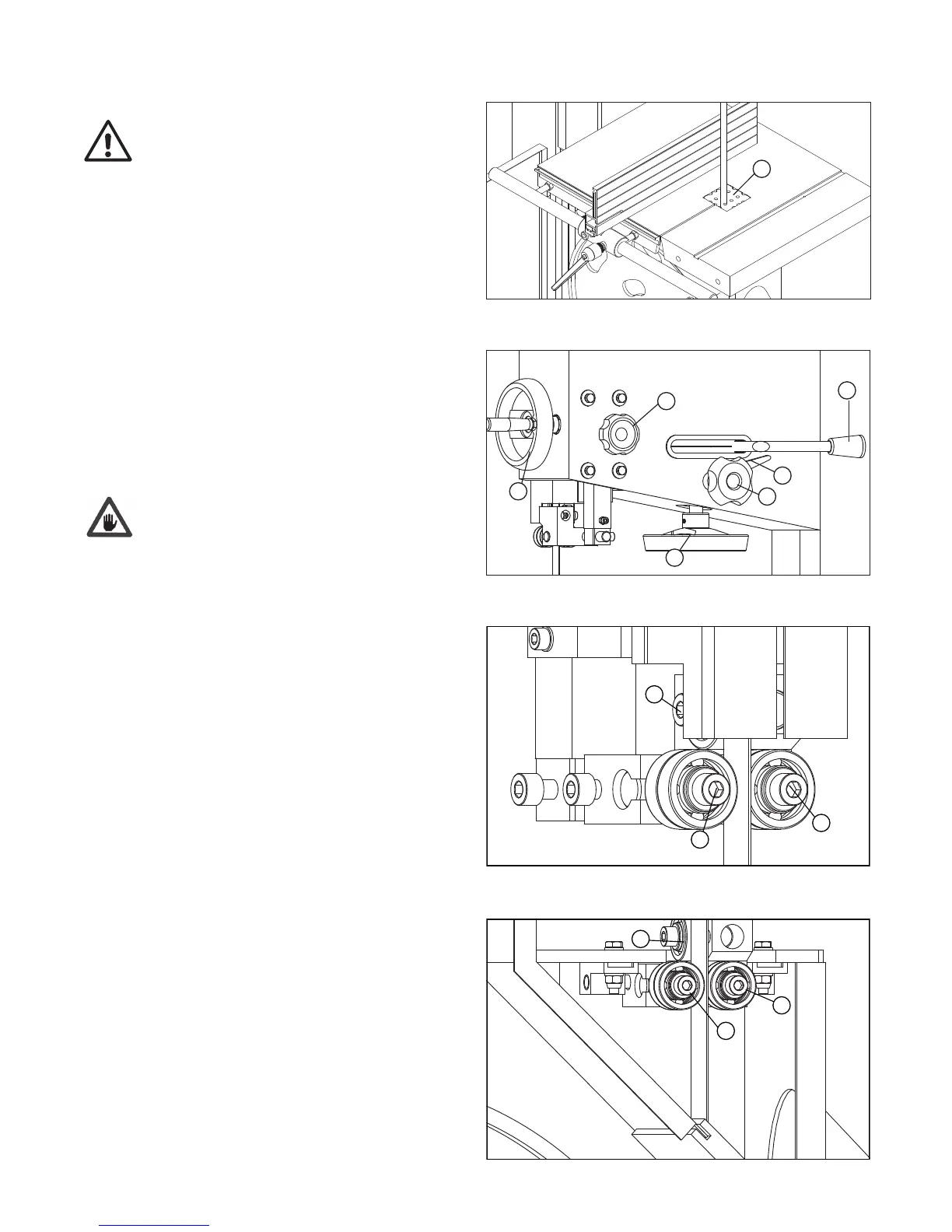

Fig 7.2

A

Blade Mounting and Adjustment

Before fitting the blade ensure that the machine is unplugged

from the power supply. Turn the brake off to allow manual

movement of the band wheels.

To mount the blade first remove the table insert (Fig 7.2, A) Place the

blade onto the bandwheel checking the teeth are in a correct position, and

then tighten the tension using the handwheel (Fig 7.3, A). The correct

tension value is indicated on the tension scale inside the upper door, the

indicated value corresponds to the width of the blade.

Turn the bandwheels manually, checking that the blade does not interfere

with any fixed parts and that the blade is placed correctly on the

bandwheels. The points of the teeth should slightly protrude over the edge

of the bandwheels. To adjust the blade position on the bandwheels slacken

the locking lever (Fig 7.3, B), and then turn the knob (Fig 7.3, C): the

blade will move inwards when turn the knob clockwise and the blade will

move further out when turn the knob anticlockwise; A quarter of one circle

is sufficient to make a noticeable displacement. Tighten the locking lever

after the blade is positioned correctly.

Reinstall the table insert, close the band wheels accessing doors.

After use we recommend slackening the blade tension, and to display a

visible sign on the machine advising of this procedure.

Remeber to check and re-tension before use. This operation prevents

damage to the bandwheel tyres.

Setting the Blade Guard and Guides

Adjusting the Saw Blade Guard

The adjustable saw band guard should be positioned as close as possible to

the work piece. To adjust the height, release the locking knob (Fig 7.3, D)

and turn the hand wheel (Fig 7.3, E) to move the guard up or down. Lock

the knob once the correct guard position is obtained. This operation must

always be carried out when the machine has stopped.

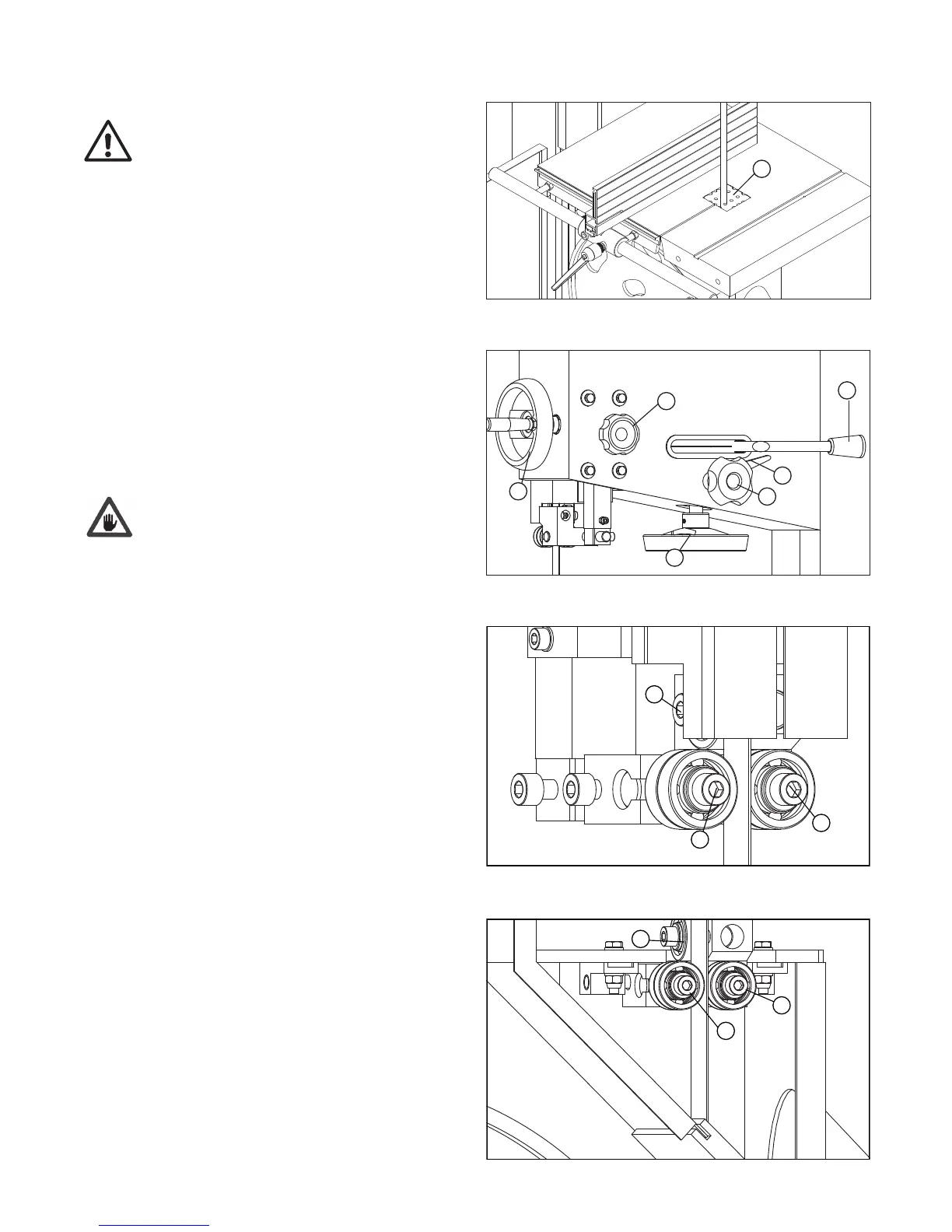

Roller Bearings Blade Guide

The roller bearings should be positioned as close to the blade as possible

but without touching it, to help maintain the correct cutting direction

during use. The positioning of these bearings is controlled by screw A of Fig

7.4. Once they have been adjusted, tighten screw A. They should be 2 mm

behind the teeth of the blade. The rear bearing prevents excessive backward

movement of the blade during operation and should be 1 - 2 mm from the

back of the blade. This can be adjusted using screw B of Fig 7.4.

Lower Saw Blade Guide

The roller bearings should be positioned as close to the blade as possible

but without touching it, to help maintain the correct cutting direction during

use. The positioning of these rollers is controlled by screw A of Fig 7.5.

Once adjusted, tighten screw A. They should be 2 mm behind the teeth of

the blade. The thrust shaft prevents excessive backwards movement of the

blade during operation and should be 1 - 2 mm from the back of the blade.

This can be adjusted using screw B of Fig 7.5.

CAUTION

Fig 7.3

A

B

C

D

E

F

Fig 7.5

-28-

4.4 BLADE MOUNTING AND ADJUSTMENT

- To mount blade first remove the table insert (A of FIG.4.4.1)

Place the blade onto the bandwheel checking the teeth are

in a correct position, and then tighten the tension using the

handwheel (A of FIG.4.4.2). The correct tension value is

indicated on the tension scale inside the upper door, the

indicated value corresponds to the width of the blade.

- Turn the bandwheels manually, checking that the blade does

not interfere with any fixed parts and that the blade is placed

correctly on the bandwheels. The points of the teeth should

slightly protrude over the edge of the bandwheels. To adjust the

blade position on the bandwheels slacken the locking lever( B

of FIG.4.4.2), and then turn the knob(C of FIG.4.4.2): the blade

will move inwards when turn the knob clockwise and the blade

will move further out when turn the knob anticlockwise; A quarter

of one circle is sufficient to make a noticeable displacement.

Tighten the locking lever after the blade is positioned correctly.

- Then reinstall the table insert, close the band wheels accessing

doors.

After use we recommend slackening the blade tension, and to

display a visible sign on

the machine advising of this procedure.

Remeber to check and re-tension before use. This operation

prevents damage to the bandwheel tyres.

Fig.4.4.1

A

Fig.4.4.2

A

B

C

CAUTION

4.5 SETTING BLADE GUARD & GUIDE

AJUSTING THE SAW BLADE GUARD

The adjustable saw band guard should be positioned as close

as possible to the workpiece. To adjust the height, release the

locking knob(D of Fig.4.4.2 ) and turn the handwheel (E of

Fig.4.4.2) to adjust the guard up or down. Lock the knob once

the correct position of guard is obtained.

This operation must always be carried out while the machine is

stopped.

ROLLER BEARINGS BLADE GUIDE

The roller bearings should lightly touch the blade, to prevent

vibration during operation and ensure correct direction of

cutting. The positioning of these bearings is controlled by screw

“A”(Fig.4.5.1), once they have been adjusted, tighten the screw

“A”(Fig.4.5.1); they should be 2mm behind the teeth of the

blade.The rear bearing prevents excessive backward movement

of the blade whilst in operation , and should be 1-2 mm from the

back of the blade: this can be adjusted by srew “B”(Fig.4.5.1).

LOWER SAW BLADE GUIDE

- To roller bearing should lightly touch the blade, to prevent

vibration during operation and ensure correct direction of

cutting. The positioning of these rollers is controlled by screw

“A”(Fig.4.5.2), once they have been adjusted, tighten the screw

“A”(Fig.4.5.2); they should be

2 mm behind the teeth of the

blade.The thrust shaftprevents excessive backward movement

of the blade whilst in operation , and should be 1-2 mm from the

back of the blade: this can be adjusted by srew “B”(Fig.4.5.2).

Fig.4.5.1

D

E

A

A

B

Fig.4.5.2

-28-

4.4 BLADE MOUNTING AND ADJUSTMENT

- To mount blade first remove the table insert (A of FIG.4.4.1)

Place the blade onto the bandwheel checking the teeth are

in a correct position, and then tighten the tension using the

handwheel (A of FIG.4.4.2). The correct tension value is

indicated on the tension scale inside the upper door, the

indicated value corresponds to the width of the blade.

- Turn the bandwheels manually, checking that the blade does

not interfere with any fixed parts and that the blade is placed

correctly on the bandwheels. The points of the teeth should

slightly protrude over the edge of the bandwheels. To adjust the

blade position on the bandwheels slacken the locking lever( B

of FIG.4.4.2), and then turn the knob(C of FIG.4.4.2): the blade

will move inwards when turn the knob clockwise and the blade

will move further out when turn the knob anticlockwise; A quarter

of one circle is sufficient to make a noticeable displacement.

Tighten the locking lever after the blade is positioned correctly.

- Then reinstall the table insert, close the band wheels accessing

doors.

After use we recommend slackening the blade tension, and to

display a visible sign on

the machine advising of this procedure.

Remeber to check and re-tension before use. This operation

prevents damage to the bandwheel tyres.

Fig.4.4.1

A

Fig.4.4.2

A

B

C

CAUTION

4.5 SETTING BLADE GUARD & GUIDE

AJUSTING THE SAW BLADE GUARD

The adjustable saw band guard should be positioned as close

as possible to the workpiece. To adjust the height, release the

locking knob(D of Fig.4.4.2 ) and turn the handwheel (E of

Fig.4.4.2) to adjust the guard up or down. Lock the knob once

the correct position of guard is obtained.

This operation must always be carried out while the machine is

stopped.

ROLLER BEARINGS BLADE GUIDE

The roller bearings should lightly touch the blade, to prevent

vibration during operation and ensure correct direction of

cutting. The positioning of these bearings is controlled by screw

“A”(Fig.4.5.1), once they have been adjusted, tighten the screw

“A”(Fig.4.5.1); they should be 2mm behind the teeth of the

blade.The rear bearing prevents excessive backward movement

of the blade whilst in operation , and should be 1-2 mm from the

back of the blade: this can be adjusted by srew “B”(Fig.4.5.1).

LOWER SAW BLADE GUIDE

- To roller bearing should lightly touch the blade, to prevent

vibration during operation and ensure correct direction of

cutting. The positioning of these rollers is controlled by screw

“A”(Fig.4.5.2), once they have been adjusted, tighten the screw

“A”(Fig.4.5.2); they should be

2 mm behind the teeth of the

blade.The thrust shaftprevents excessive backward movement

of the blade whilst in operation , and should be 1-2 mm from the

back of the blade: this can be adjusted by srew “B”(Fig.4.5.2).

Fig.4.5.1

D

E

7. Installation and Operation

Loading...

Loading...